Aluminium profile bending machine

An aluminum profile and bending technology, which is applied in the field of aluminum bending processing, can solve problems such as inconvenient installation and manufacturing, complex transmission structure, and high energy loss, so as to save driving energy and solve the effect of complex transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

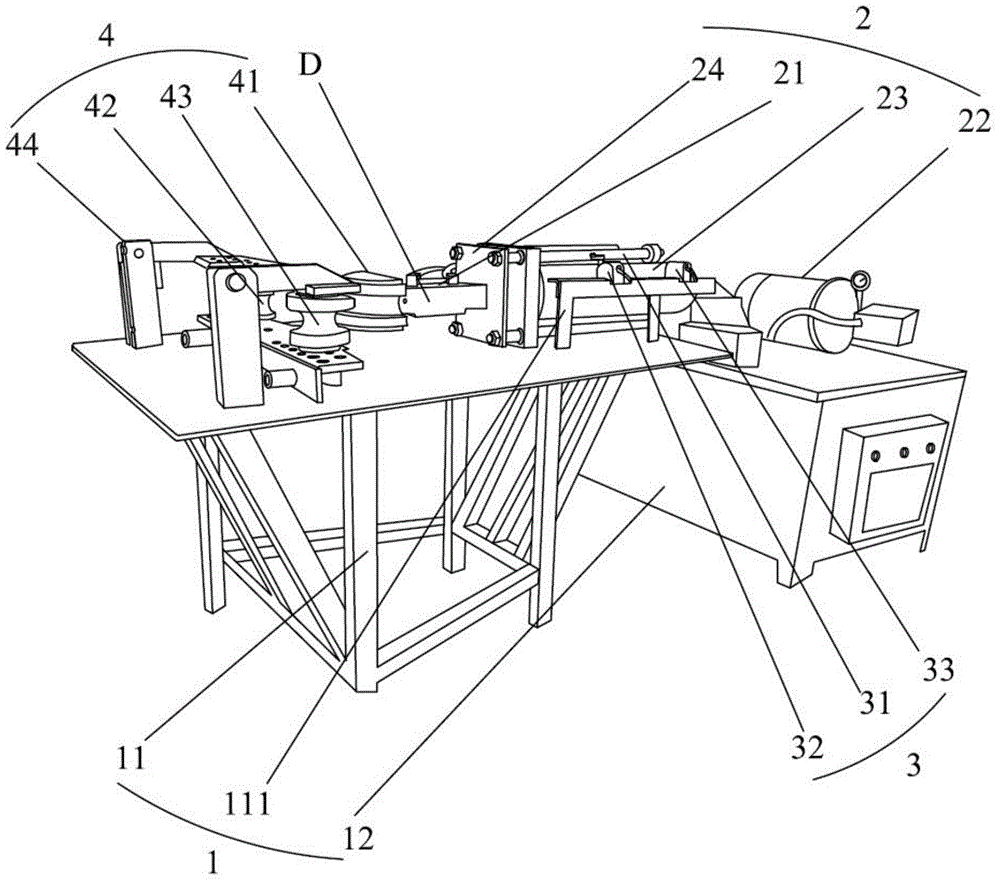

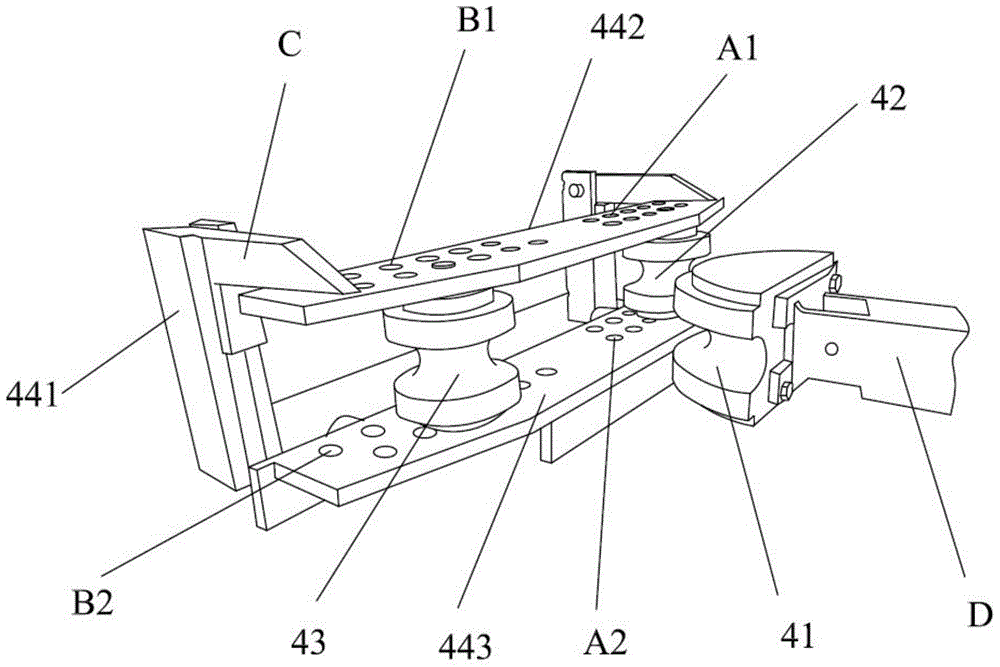

[0025] Please also see figure 1 , figure 2 and image 3 , The aluminum profile bending machine of the present invention includes a frame 1 , a push-pull mechanism 2 , an arc adjustment limit mechanism 3 and a bending mechanism 4 .

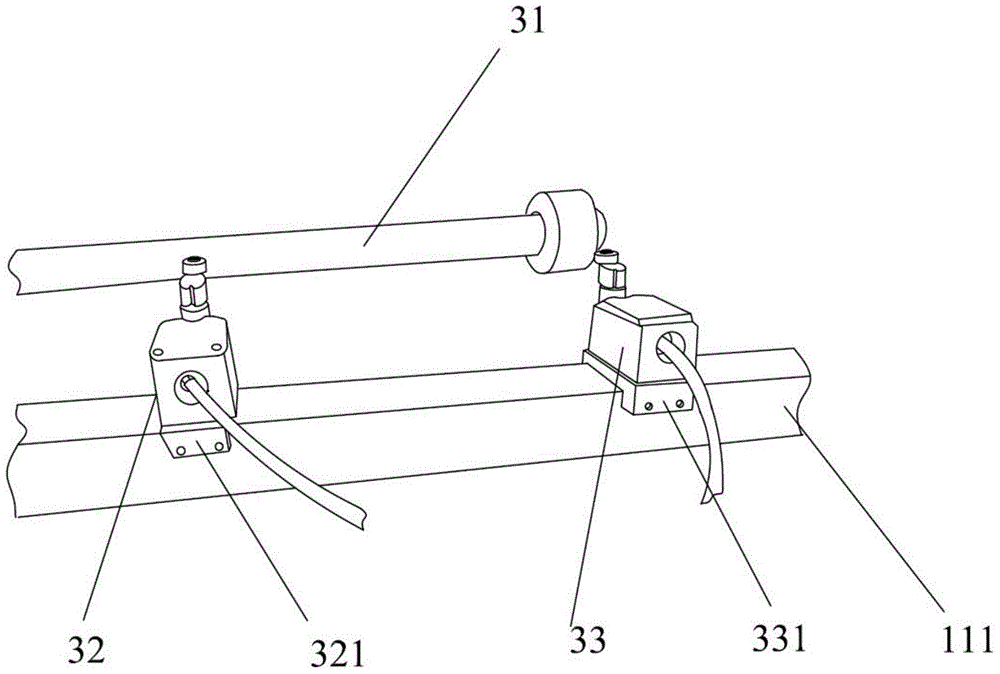

[0026] The frame 1 includes a workbench 11 and a console 12 . The workbench 11 and the console 12 are adjacently arranged. One side of the top surface of the workbench 11 is provided with a limit mechanism mounting bracket 111 and an oil cylinder mounting frame; the limit mechanism mounting bracket 111 is adjacent to the oil cylinder mounting frame.

[0027] In this embodiment, the push-pull mechanism 2 is an oil cylinder oil pump assembly, and the output shaft of the push-pull mechanism 2 is the piston rod 21 of the oil cylinder. The oil pump 22 of the push-pull mechanism 2 is installed on the console 12; the oil cylinder 23 is fixed on the oil cylinder mounting frame of the workbench 11, and its input end communicates with the output end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com