Scrapping and grinding device and operation method thereof

An operation method and scraper technology, applied in suction equipment, medical science, laparoscopy, etc., can solve problems such as poor visibility, fatigue, iatrogenic injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

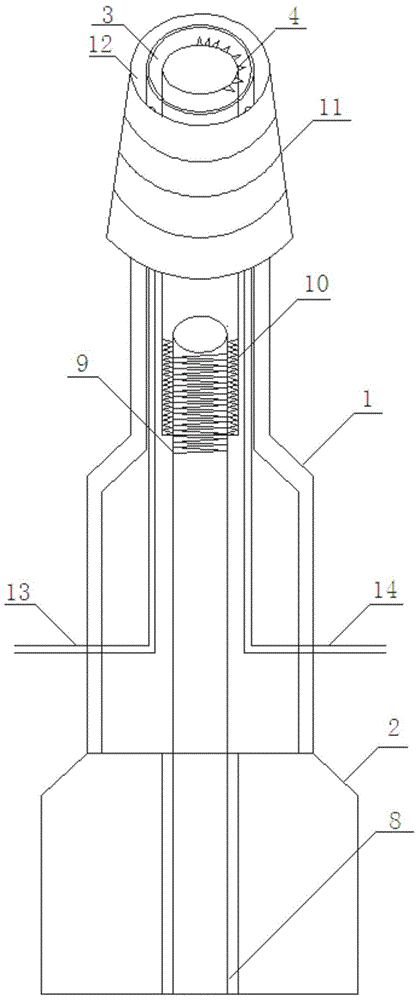

[0027] The technical solution of the present invention will be further described in conjunction with the accompanying drawings and embodiments, which is believed to be clear to those skilled in the art.

[0028] A scraper, comprising an upper shell and a base, the upper shell is provided with a bone drill cavity along the inner wall of the shell, the bone drill cavity is vertically provided with a bone drill, and the bone drill is controlled and connected by a micro motor , the rotational speed is variable, where:

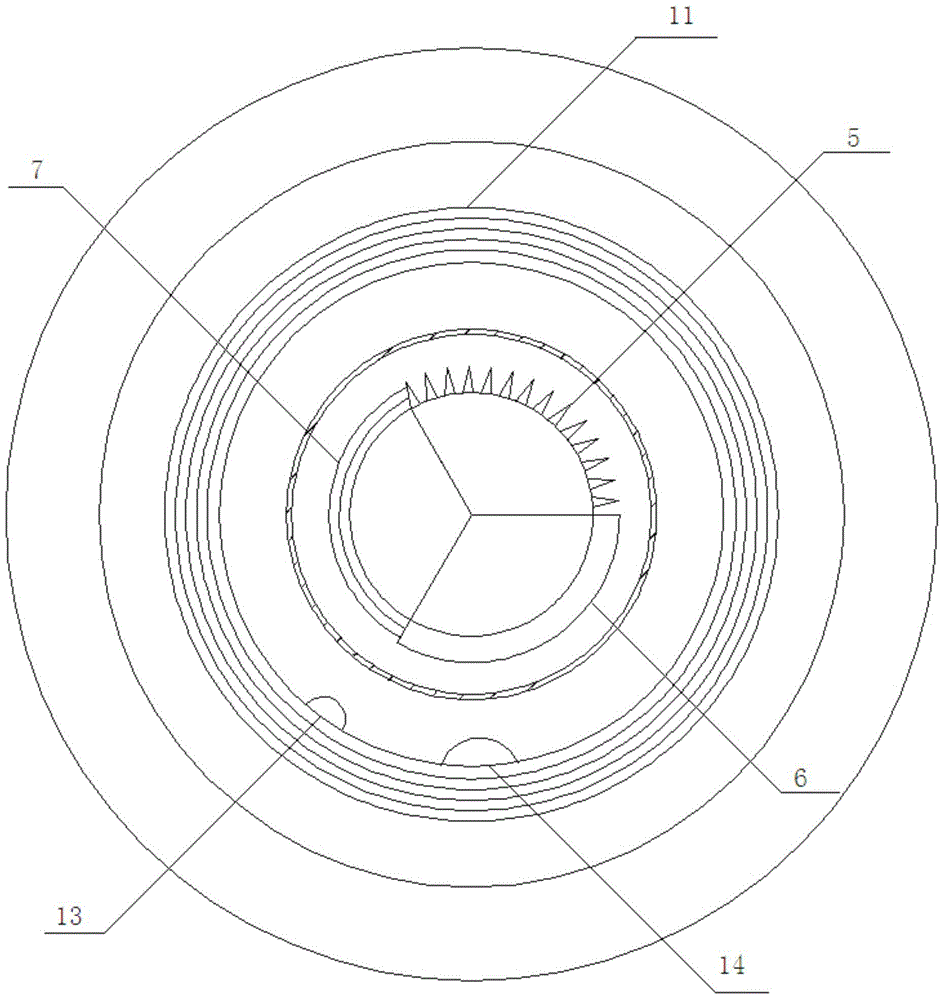

[0029] bone drills, such as figure 2 As shown, one third of the upper end of the outer wall surface is a toothed spherical surface, one third of the outer wall surface is a smooth spherical surface, and the remaining third of the outer wall surface is a stepped ridged spherical surface. The lower end of the bone drill is connected to a rotating slide The outer wall of the lower end of the bone drill bit is provided with external threads, the inner wall of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com