Bra mold cup with built-in caramel pocket and manufacturing method thereof

A production method and mold cup technology, applied in bras, clothing, bras and other directions, can solve the problems of poor fit, not enough comfortable wearing, traditional sewing methods, etc., to save the sewing process, wear comfortable, craftsmanship simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

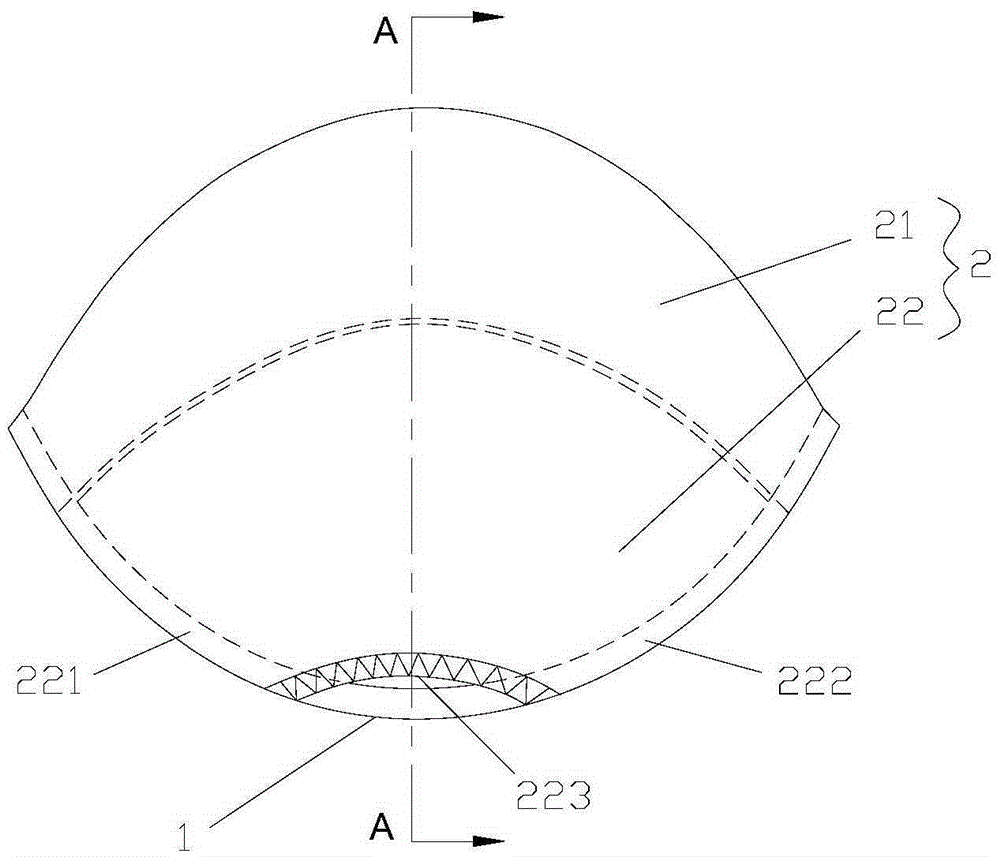

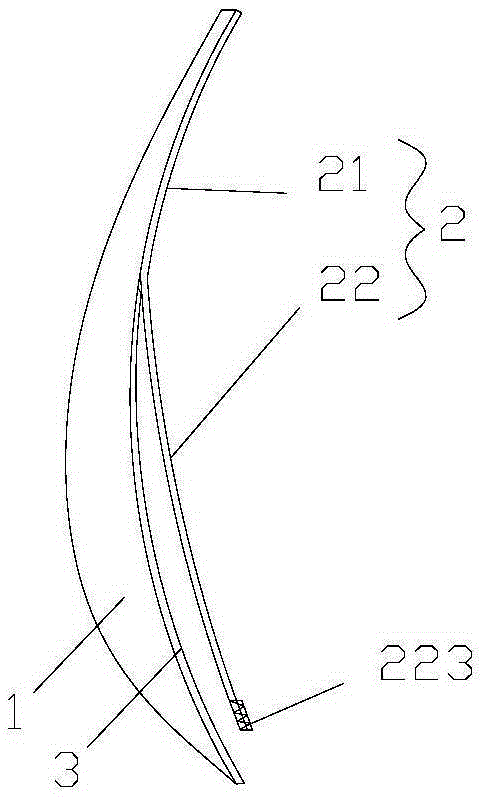

[0019] see figure 1 and figure 2 , a bra mold cup with a camry pocket inside, comprising a mold cup body 1 and a camry pocket arranged on the inner surface of the mold cup body 1 .

[0020] The inner surface of the mold cup body 1 is covered with a layer of cloth 2 , and the face cloth 2 includes adjacent bonding areas 21 and non-bonding areas 22 . Such as figure 1 As shown, in this embodiment, the bonding area 21 is located on the upper part of the mold cup body 1 , that is, the arc-shaped area extending downward for a certain distance from the edge of the bowl mouth. The bonding area 21 is completely bonded to the mold cup body 1 . The unbonded area 21 is located at the lower part of the mold cup body 1 , that is, a half-moon-shaped area extending downward from the lower end of the adhesive area 21 to the edge of the lower bowl circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com