Mushroom pickup trolley used in factory

A technology for mushrooms and factories, which is applied in the field of picking devices, can solve the problems of inability to pick mushrooms, unsuitable mushroom cultivation racks, etc., and achieves the effects of simple structure, stable force and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a limitation to the present invention.

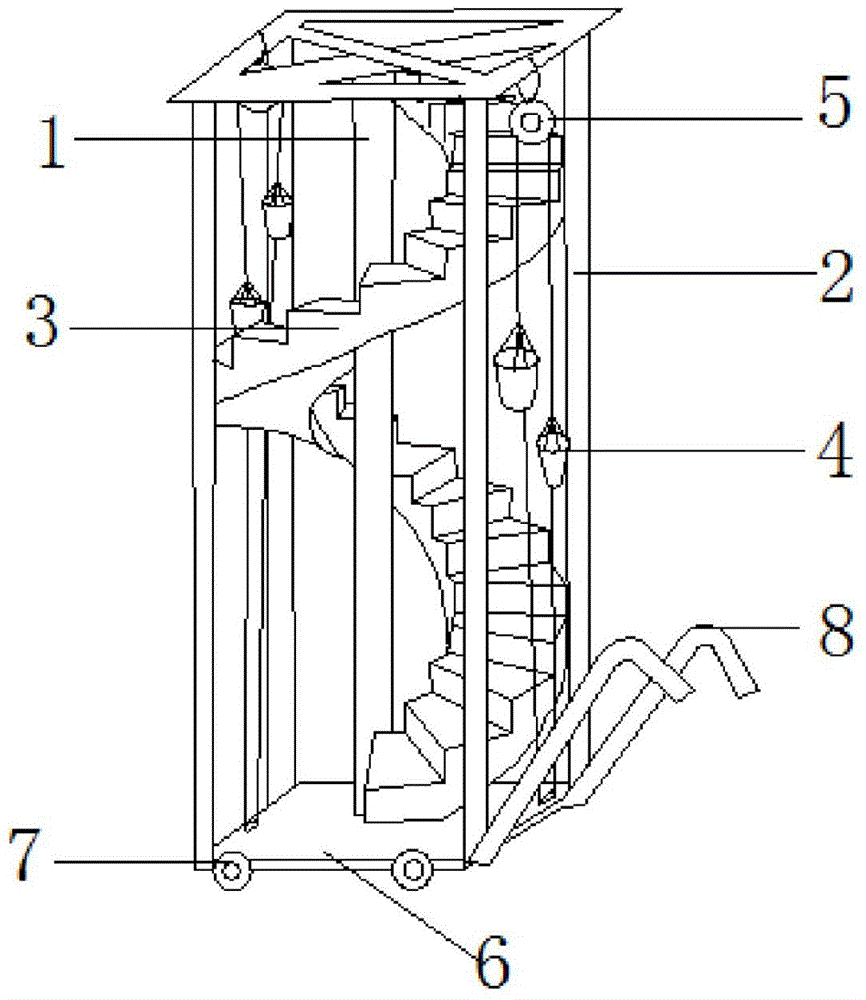

[0015] Such as figure 1 Shown, a kind of mushroom picking vehicle for factory, comprises support device, handrail 8 and roller 7, also comprises spiral ladder 3, lifting device, and described support device comprises support column 1, the support frame 2 that is vertically connected with support column 1 and supports Plate 6, support frame 2 is the square frame body of fixed spiral ladder 3, and support column 1 is positioned at the center position of support frame 2, and support plate 6 is located on the bottom surface of support frame 2, and support plate 6 bottoms connect roller 7; On the support plate 6, the inner side of the spiral ladder 3 is welded with the support column 1, the outer side of the spiral ladder 3 is welded with the support frame 2, and the spiral ladder 3 is rotated around the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com