Hose attaching structure

A technology for installing structures and hoses, which is applied to hose connecting devices, pipes/pipe joints/fittings, components of pumping devices for elastic fluids, etc. It can achieve the effect of easy position alignment, realization of position alignment, and prevention of biting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] First, the working machine according to the embodiment will be described.

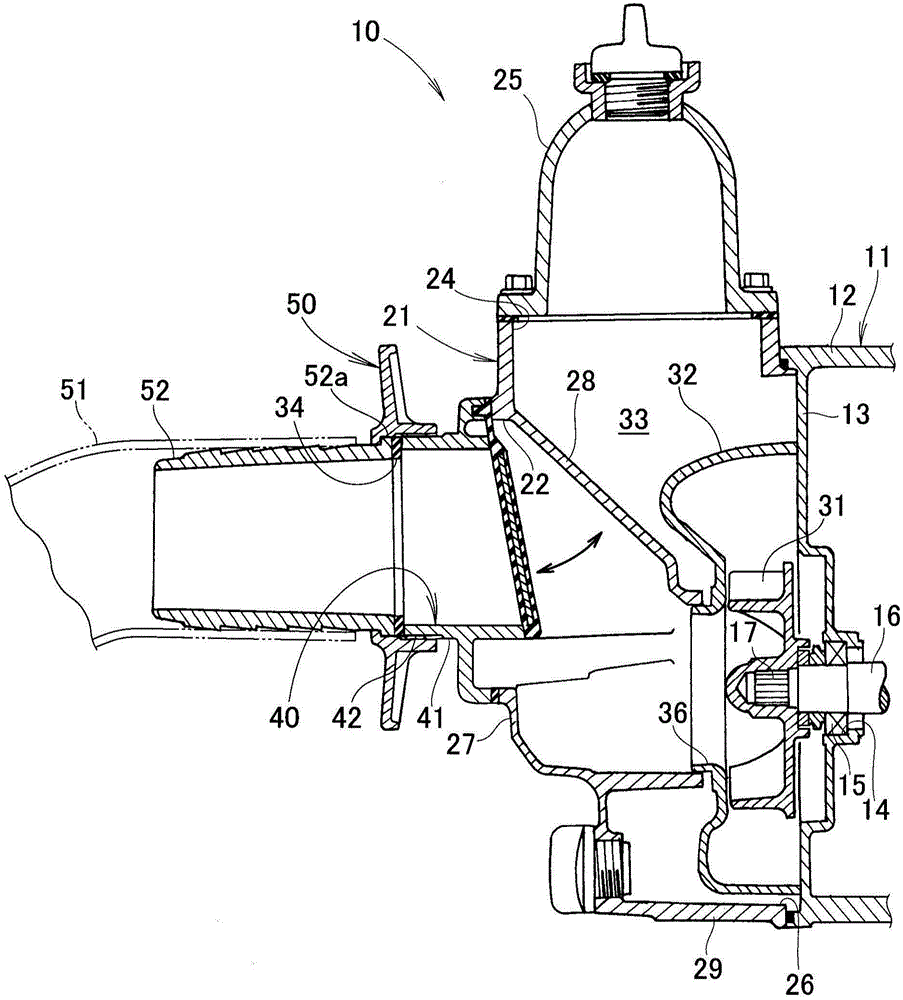

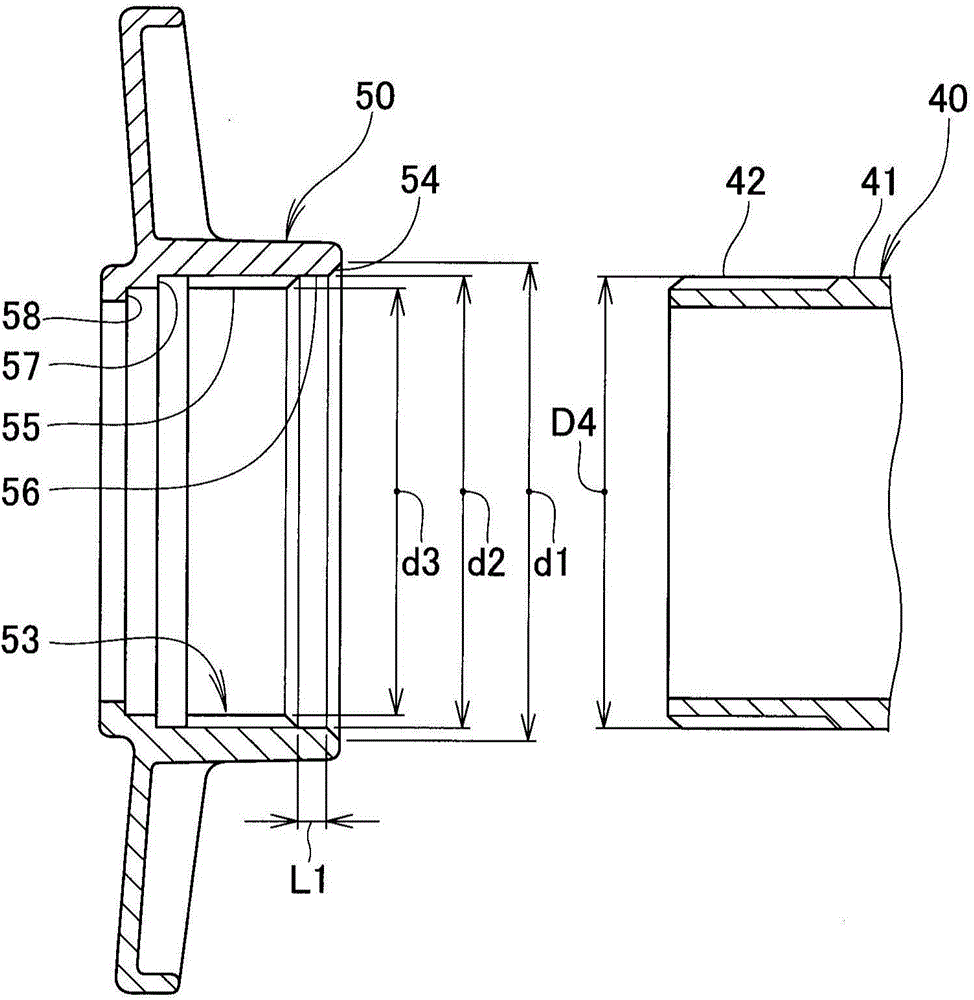

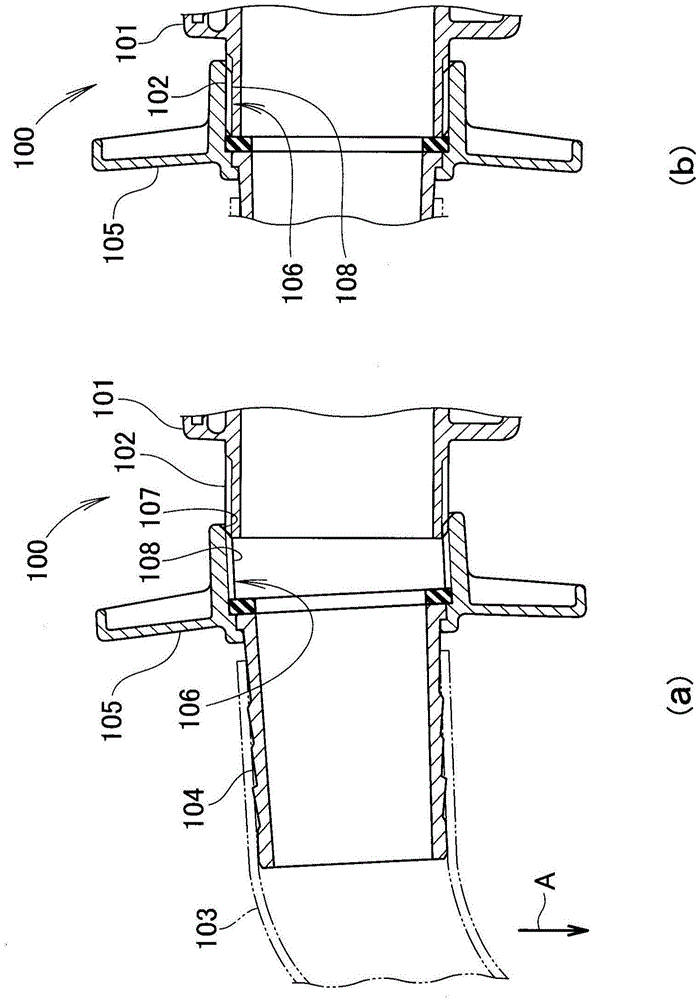

[0019] Such as figure 1 Shown; working device 10 is, for example, a water pump. The water pump 10 has: an engine 11; a housing 21 provided on the cylinder block 12 of the engine 11; a suction nozzle 40 provided on the suction port 22 of the housing 21; and a discharge nozzle 25 provided at the outlet 24 of the housing 21.

[0020] The engine 11 has: a partition wall 13 of the cylinder block 12 ; a mechanical seal 15 provided in a support hole 14 of the partition wall 13 ; and a crankshaft 16 provided rotatably on the mechanical seal 15 . An end portion 17 of the crankshaft 16 protrudes into the housing 21 , and the impeller 31 is connected to the end portion 17 .

[0021] The volute 32 is arranged in the housing 21 , and the impeller 31 is covered by the volute 32 . The opening 26 of the casing 21 is closed by the partition wall 13 , and the volute 32 is provided on the partition wall 13 , w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com