Cylinder assembly for a reciprocating piston combustion machine and cooling method

A technology of reciprocating pistons and internal combustion engines, which is applied to engine cooling, liquid cooling, cylinders, etc., and can solve problems such as increased fuel consumption, damage to parts, and heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

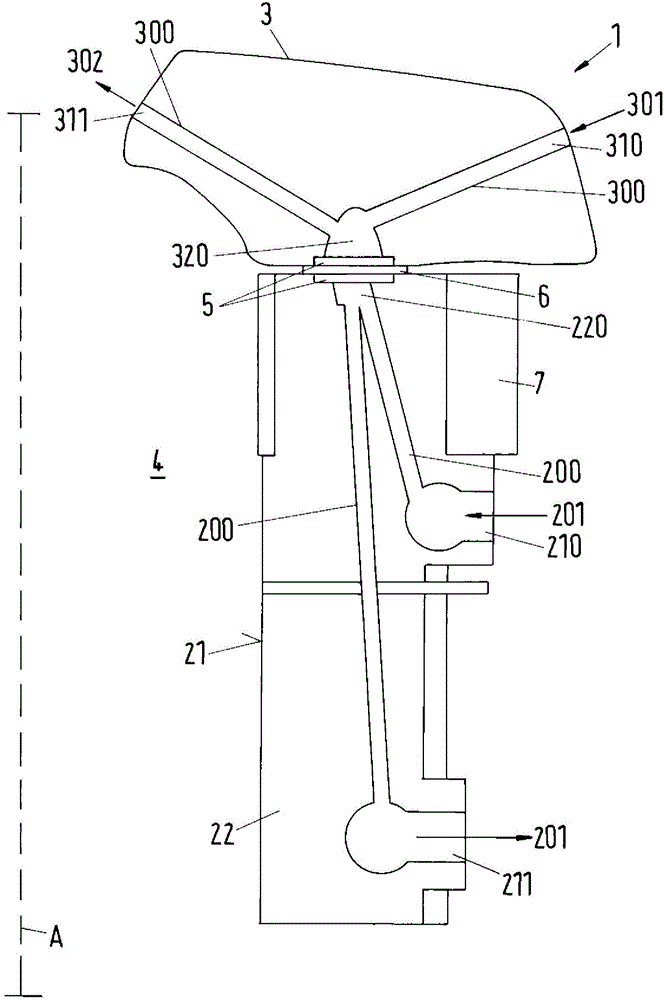

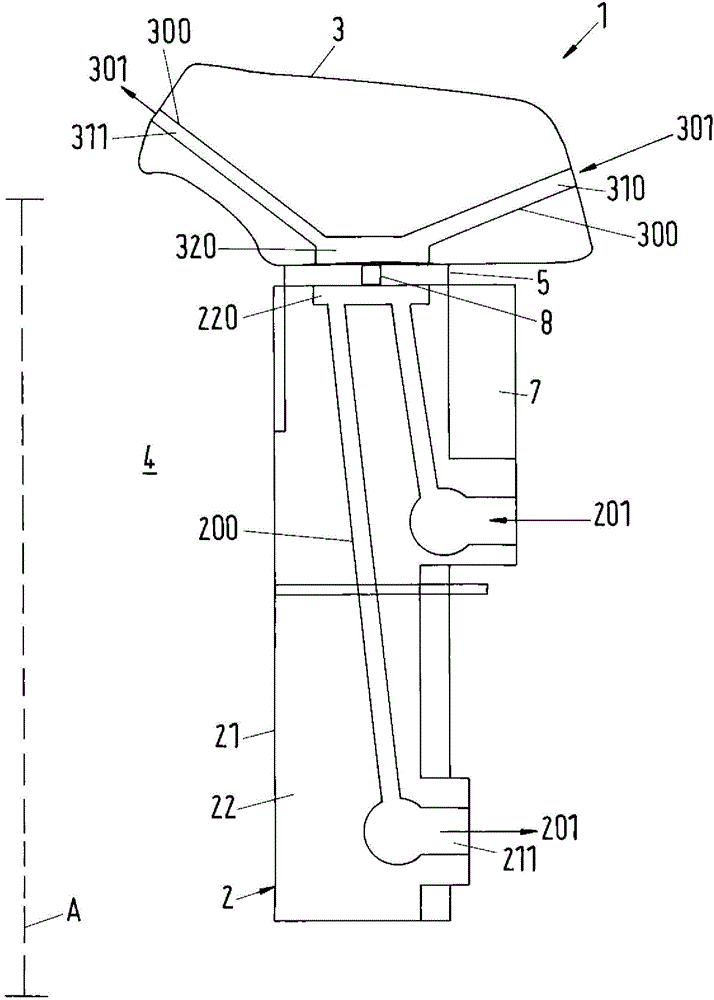

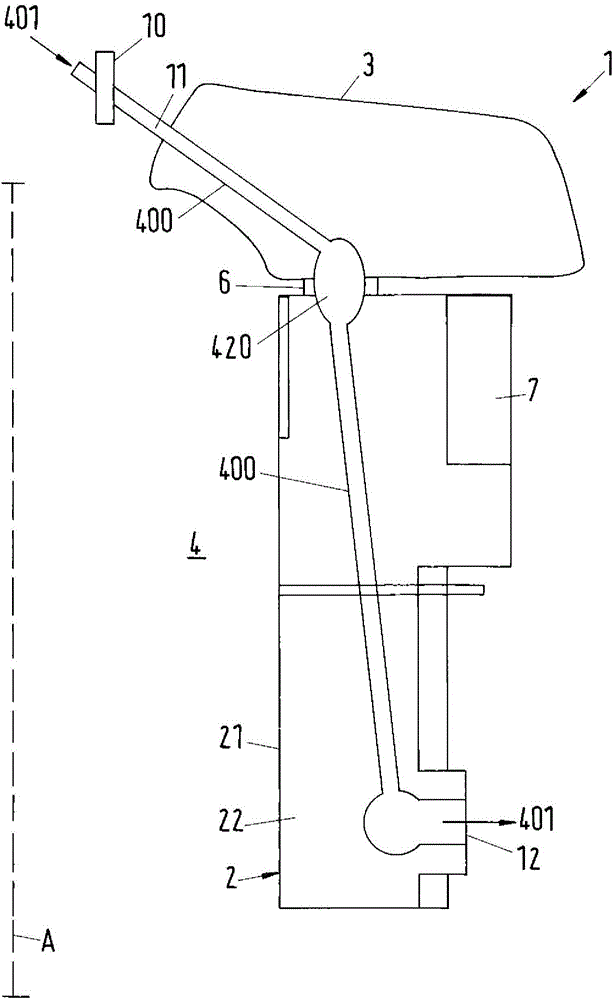

[0041] figure 1 A cylinder liner arrangement 1 according to the invention for a reciprocating piston internal combustion engine, in particular a longitudinally scavenged two-stroke large diesel engine, is shown schematically and only partially in section for the sake of clarity.

[0042] In this respect, the piston, shown not enlarged, is arranged in the cylinder liner 2 in a manner known per se, and in the operating and operating state the piston can thus be positioned in the upper center dead center position and the lower center position along the cylinder axis A of the cylinder liner 2 . Moving back and forth between the dead center positions, ie the upper side of the piston delimits the combustion space 4 together with the running surface 21 of the cylinder liner 2 and the cylinder head 3 arranged there.

[0043] The cylinder liner 2 comprises a liner cooling system 200 for cooling the cylinder liner 2 by means of a liner cooling fluid 201 , which in this example is coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com