Disposable wall casting mould and its manufacture and use

A one-time, mold technology, used in molds, mold shells/templates/work frames, on-site preparation of building components, etc., can solve the problems of wood waste, large mold capital, high labor intensity, etc., to meet the physical and mechanical properties. , The effect of reducing material cost and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

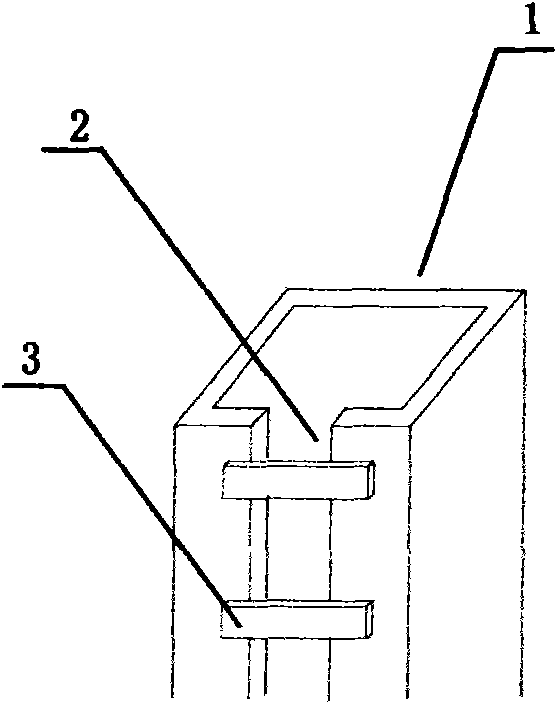

[0045] Such as figure 1 As shown, the mold is made of gelatinous material through processes such as solidification, molding, trimming and maintenance. It has a groove body 1 with a certain length, and at least one A connecting strip 3 that spans the notch 2 and is fixed on both sides of the notch 2 at both ends;

example 2

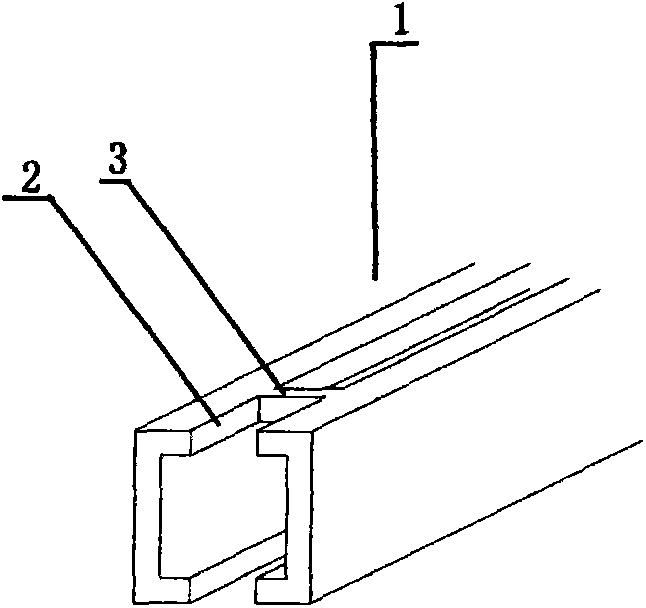

[0047] Such as figure 2 As shown, two or more sides of the tank body 1 are provided with notches 2; the two ends of the connecting band 3 are docked with the two edges of the notch 2, so that the outer surface of the connecting band 3 is in contact with the groove. The outer surface of the mouth 2 side is the same plane.

example 3

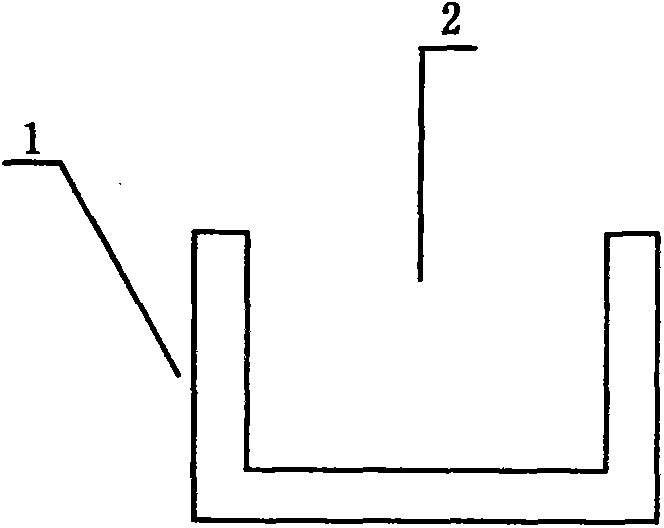

[0049] Such as image 3 As shown, the width of the notch 2 is the width of the side of the groove body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com