Surface protection film and optical part bonded with the surface protection film

A surface protection film, single-sided technology, used in optical elements, optics, film/sheet adhesives, etc., can solve the problems of air bubbles mixed in the adhesive layer, surface protection film separation, and reduced bonding area, etc. Reliable protection, less pollution, and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

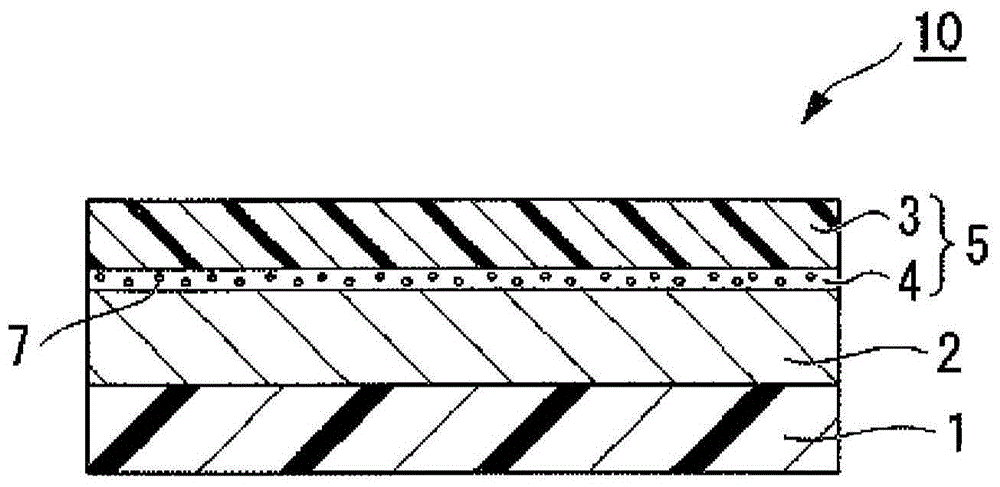

[0077] (manufacture of surface protection film)

[0078] Addition reaction type polysiloxane (product name is SRX-345 of 5 parts by weight, manufactured by Dow Corning Toray Co., Ltd.), 7.5 parts by weight of tri-n-butylmethylammonium bistrifluoromethanesulfonimide (FC -4400, 3M company (スリーエム company) manufactures) 10% ethyl acetate solution, the toluene of 95 parts by weight and ethyl acetate are the mixed solvent of 1:1, the platinum catalyst of 0.05 parts by weight (the product name is SRX-212, Dow Corning Toray Co., Ltd.) were mixed together and stirred and mixed to prepare the coating material for forming the release agent layer of Example 1. Using a Meller rod, the paint for forming the release agent layer of Example 1 was applied to the surface of a polyethylene terephthalate film having a thickness of 38 μm so that the thickness after drying was 0.2 μm. , and dried in a hot air circulation oven at 120° C. for 1 minute to obtain the release film of Example 1. On the ...

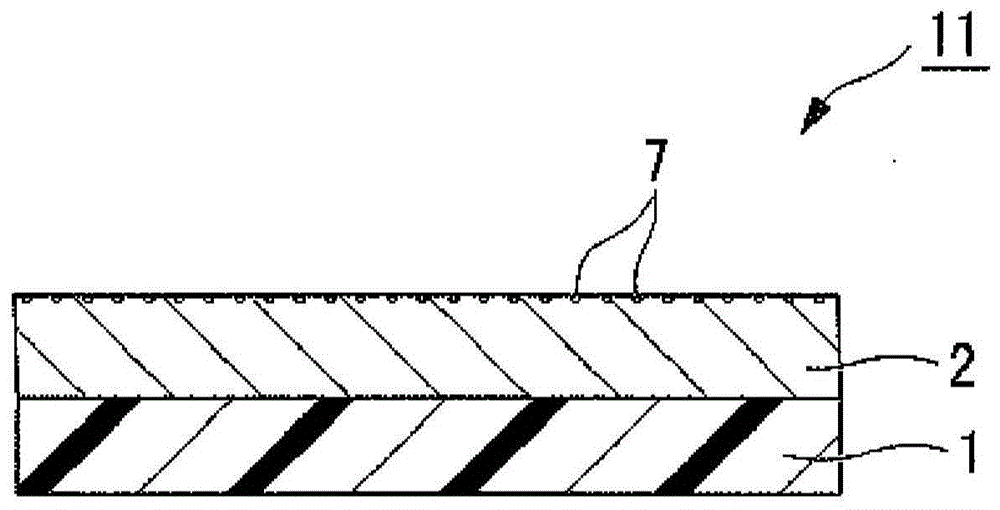

Embodiment 2

[0080] Except having applied the paint for forming the release agent layer of Example 1 so that the thickness after drying might become 0.1 micrometer, it carried out similarly to Example 1, and obtained the surface protection film of Example 2.

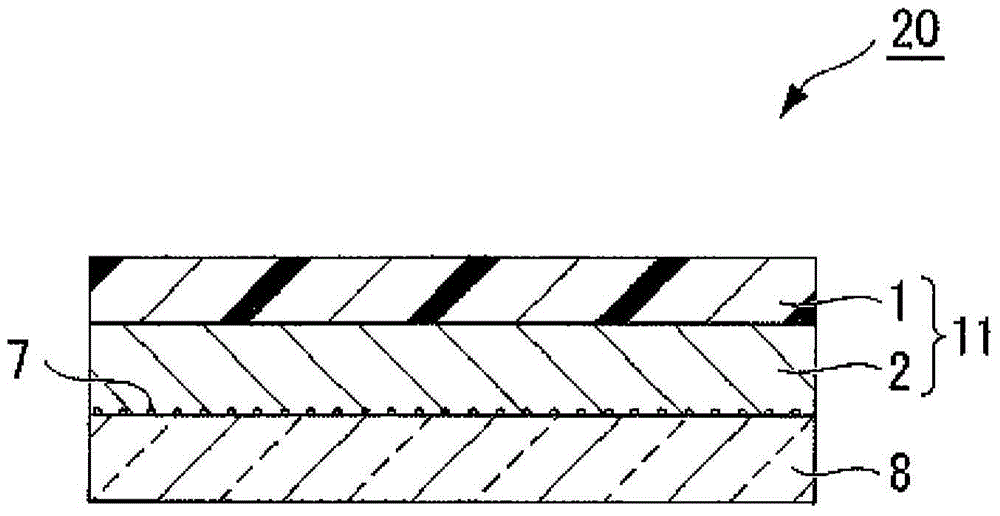

Embodiment 3

[0082] Except that SRX-211 (product name) manufactured by Dow Corning Toray Co., Ltd. was used as the addition reaction polysiloxane of Example 1, the same operation was carried out as in Example 1, and the surface protection of Example 3 was obtained. membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com