Multistage hydrogenation technology for producing hydrogen peroxide by anthraquinone process

A hydrogen peroxide, anthraquinone method technology, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, chemical recovery, inorganic chemistry, etc. Viscosity, prolong the regeneration cycle, improve the effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

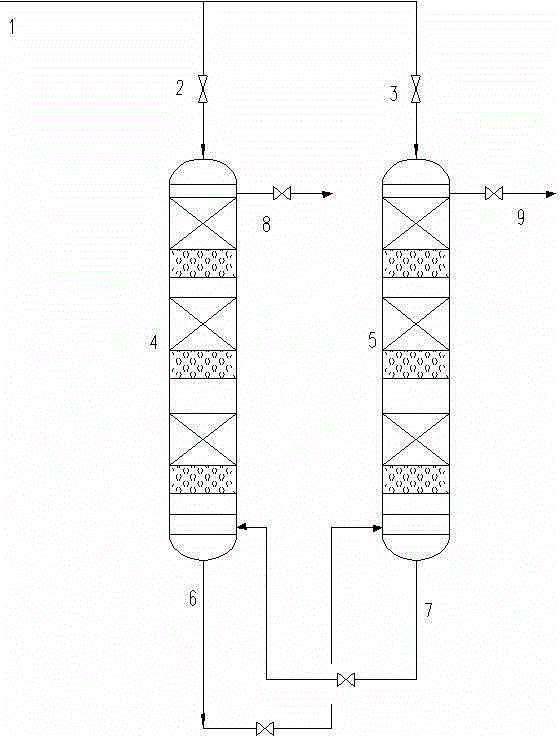

Embodiment 1

[0027] There are two fixed-bed hydrogenation reactors I and II, which are connected in series, and each reactor is equipped with three beds, and the hydrogenation catalyst and the silica regeneration agent are respectively filled according to the "ABAB" method. Fill catalyst 0.45m 3 , a total of 0.157m regenerant is filled 3 . The hydrogenation temperature is 45°C, and the hydrogenation pressure is 0.25MPa. The working liquid and hydrogen enter from the top of reactor I, and after hydrogenation reaction and regeneration occur from top to bottom in the bed, they flow out through the bottom of reactor I, and then enter the bottom of reactor II, and flow from bottom to bottom in the bed. The hydrogenation reaction and regeneration on the upper side flow out from the top of the reactor II; then manually switch the flow direction of the material every hour. After treatment by this method, the contents of hydroanthraquinone and tetrahydroanthraquinone in the hydrogenation solutio...

Embodiment 2

[0029] There are three fixed-bed hydrogenation reactors I, II and III, which are connected in series. Each reactor is equipped with a bed, and the bed is filled with two stages of anthraquinone hydrogenation catalyst and one stage of alumina according to the "ABA" method. Regenerant, a total of 0.45m of catalyst is filled in the two reactors 3 , a total of 0.157m regenerant is filled 3. The hydrogenation temperature is 45°C, and the hydrogenation pressure is 0.25MPa. The working fluid and hydrogen enter from the top of reactor I, and the hydrogenation reaction occurs from top to bottom in the bed, flows out through the bottom of reactor I, and then enters the bottom of reactor II, and occurs in the bed from bottom to top After the hydrogenation reaction, it flows out from the top of the reactor II; then it enters the top of the reactor III, and flows out from the bottom of the reactor III after the hydrogenation reaction occurs from top to bottom in the bed. After treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing resistance | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com