Device for regulating location of mass center of transfer trolley

A transfer vehicle, center of mass technology, applied in transportation and packaging, the superstructure of trucks, body and other directions, can solve the problems of backward movement of the center of mass, uneven distribution of the grounding specific pressure of the crawler, too large rear, etc., and achieves a simple structure. , Eliminate the uninstallation steps, and the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

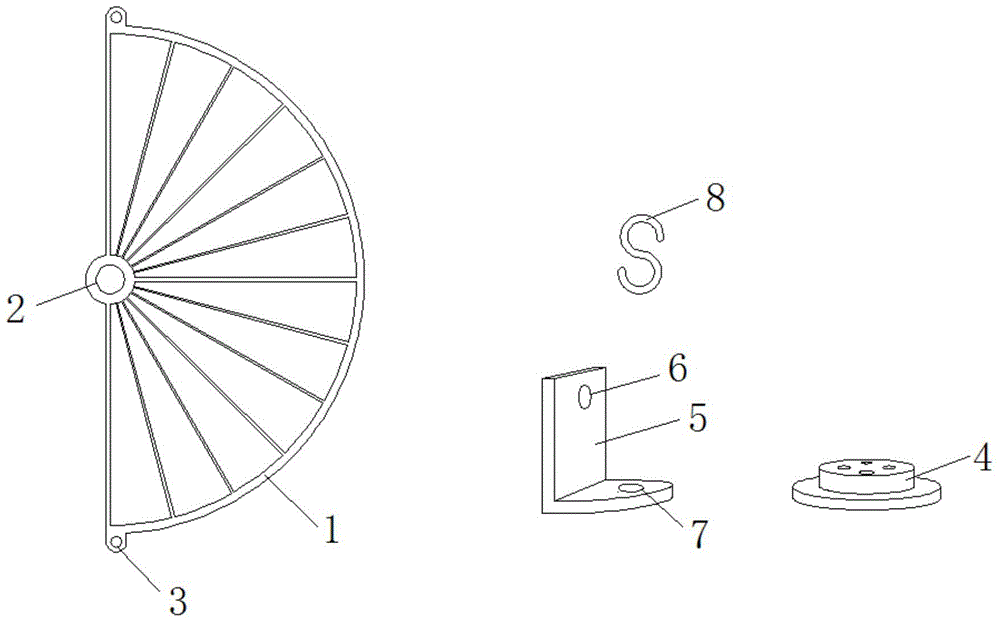

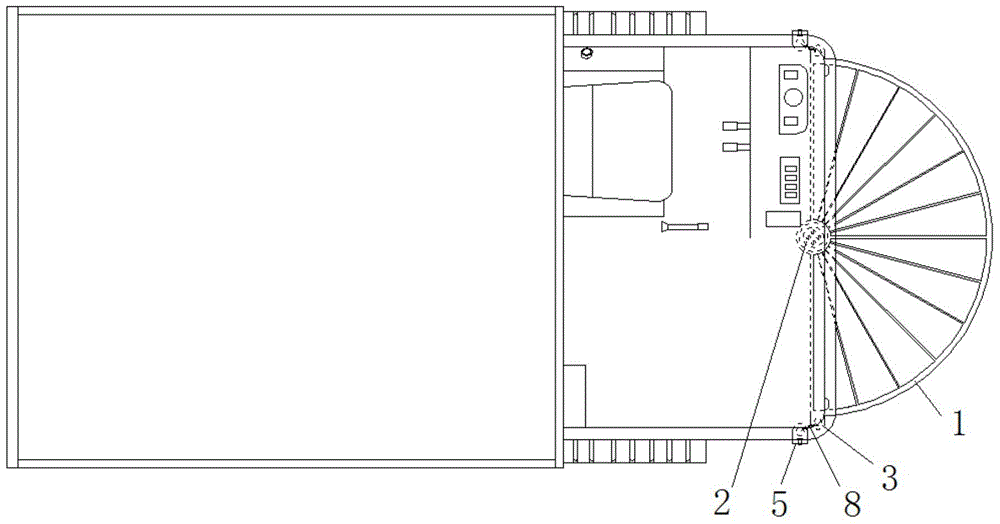

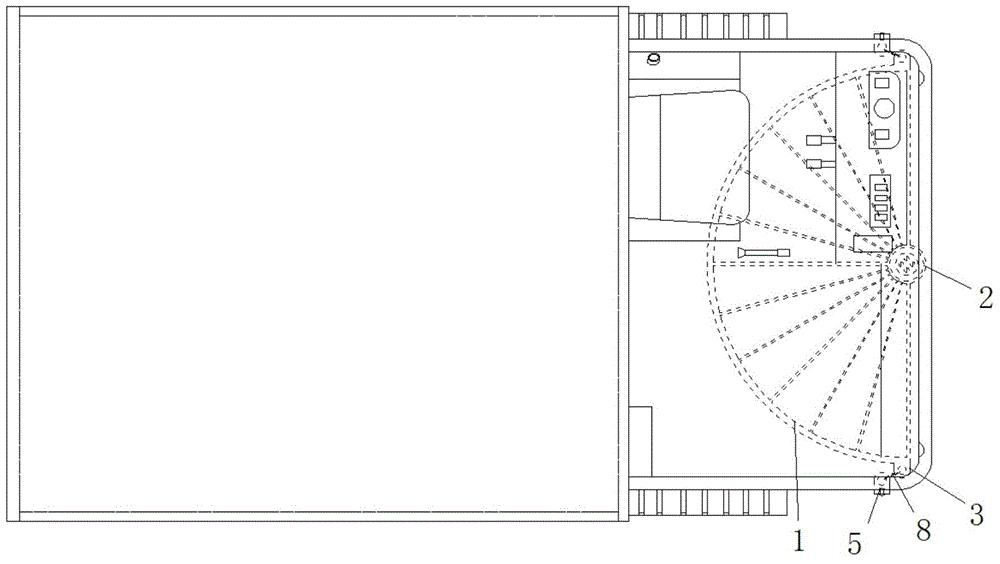

[0014] like figure 1 A device for adjusting the position of the center of mass of the transfer vehicle shown, the device includes a tray 1, a limit block 4, two fixing frames 5 and two hooks 8; the tray 1 is a semicircular frame made of metal strips Intersect and connect with at least five metal strips from the center of the circle and the arc edge of the frame, the first fixing hole 3 is formed at the intersection of the arc edge of the semicircular frame and the two radius sides, and the center of the pallet is provided with a limit hole 2 , the limit hole 2 is adapted to the size of the limit block 4; the limit block 4 is cylindrical, and is provided with a mounting hole connecting the top surface and the bottom surface, and the bottom is provided with a baffle plate; the fixed frame 5 is formed by vertically intersecting The vertical plate is composed of a vertical plate and a horizontal plate, the vertical plate is provided with a second fixing hole 6, and the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com