Component for adjusting mass center position of crawler type transfer trolley

A transfer vehicle, crawler type technology, which is applied to vehicle components, superstructure of trucks, transportation and packaging, etc., can solve the problems of backward movement of the center of mass, excessive rear part, and uneven distribution of the ground specific pressure of the crawler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

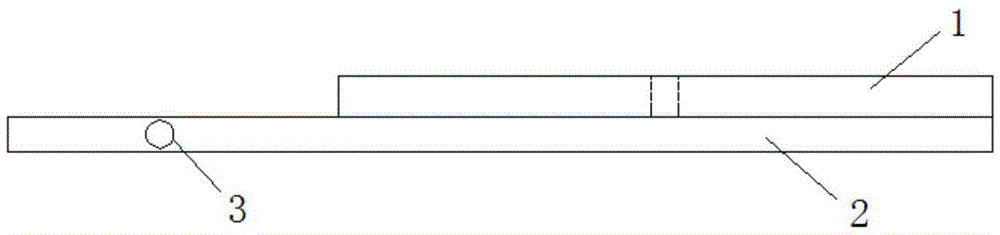

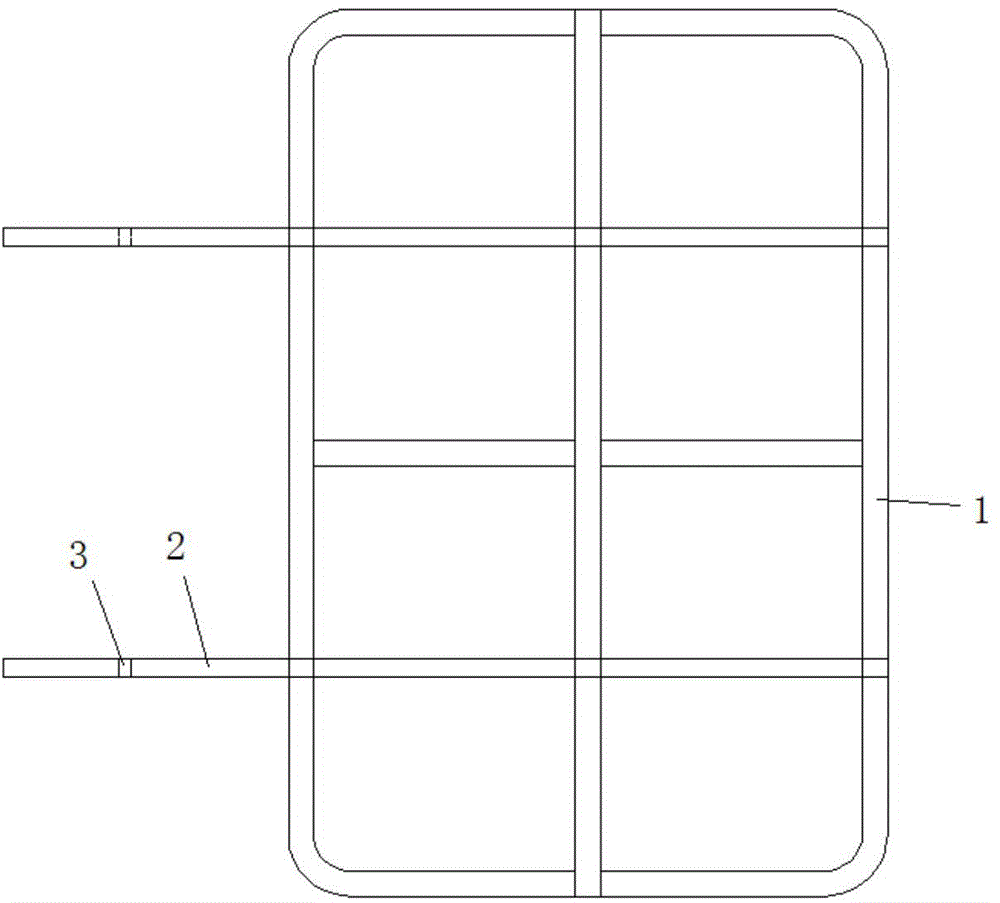

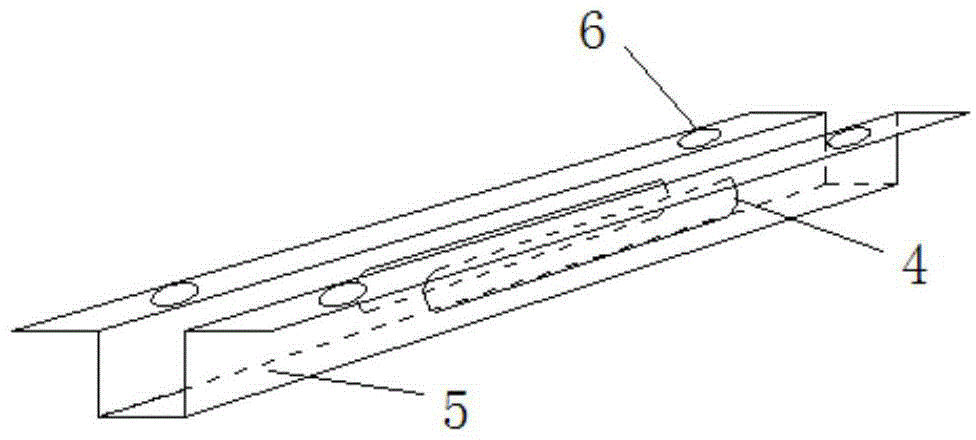

[0023] Such as figure 1 , 2 , A kind of assembly shown in 3 and 4 to adjust the center of mass position of the crawler-type transfer vehicle, including a tray part and a fixed part; the tray part includes a tray 1 and two support beams 2, and one end of the support beam 2 is connected to the tray 1 is fixedly connected and the other end is provided with a through hole 3, the through hole direction of the through hole 3 is parallel to the plane of the tray 1; the fixed part includes two chute 5, the cross section of the chute 5 is Ω-shaped, Two installation holes 6 are respectively arranged on the two wings of the chute, and the chute is also provided with elongated holes 4, and the elongated holes 4 are symmetrically arranged on the two side plates of the chute.

Embodiment 2

[0025] Such as Figure 5 , 6 , 7, 8 shows an assembly for adjusting the position of the center of mass of a crawler-type transfer vehicle, including a tray part and a fixed part; the tray part includes a tray 1 and two support beams 2, and one end of the support beam 2 is connected to the tray 1 is fixedly connected and the other end is provided with a through hole 3, the through hole direction of the through hole 3 is perpendicular to the plane of the tray 1; the fixed part includes two chute 5, the cross section of the chute 5 is Ω-shaped, Two installation holes 6 are respectively arranged on the two wings of the chute, and the chute is also provided with a long hole 4, and the long hole 4 is arranged on the bottom plate of the chute.

[0026] The installation process of above-mentioned two embodiments is:

[0027] Each chute 5 of the device is installed on the chassis of the crawler transfer vehicle through the mounting hole 6 with a bolt, and then each support beam 2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com