Slag transfer device

A transfer device and slag technology, which is applied in the direction of transportation and packaging, mechanical conveyors, conveyors, etc., can solve the problems of flat trolley electrical equipment damage, power system damage, and insufficient slag bag capacity, so as to improve operating efficiency and improve The effect of reducing the amount of transshipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the present invention will be further described in detail below through the description of the embodiments in conjunction with the accompanying drawings.

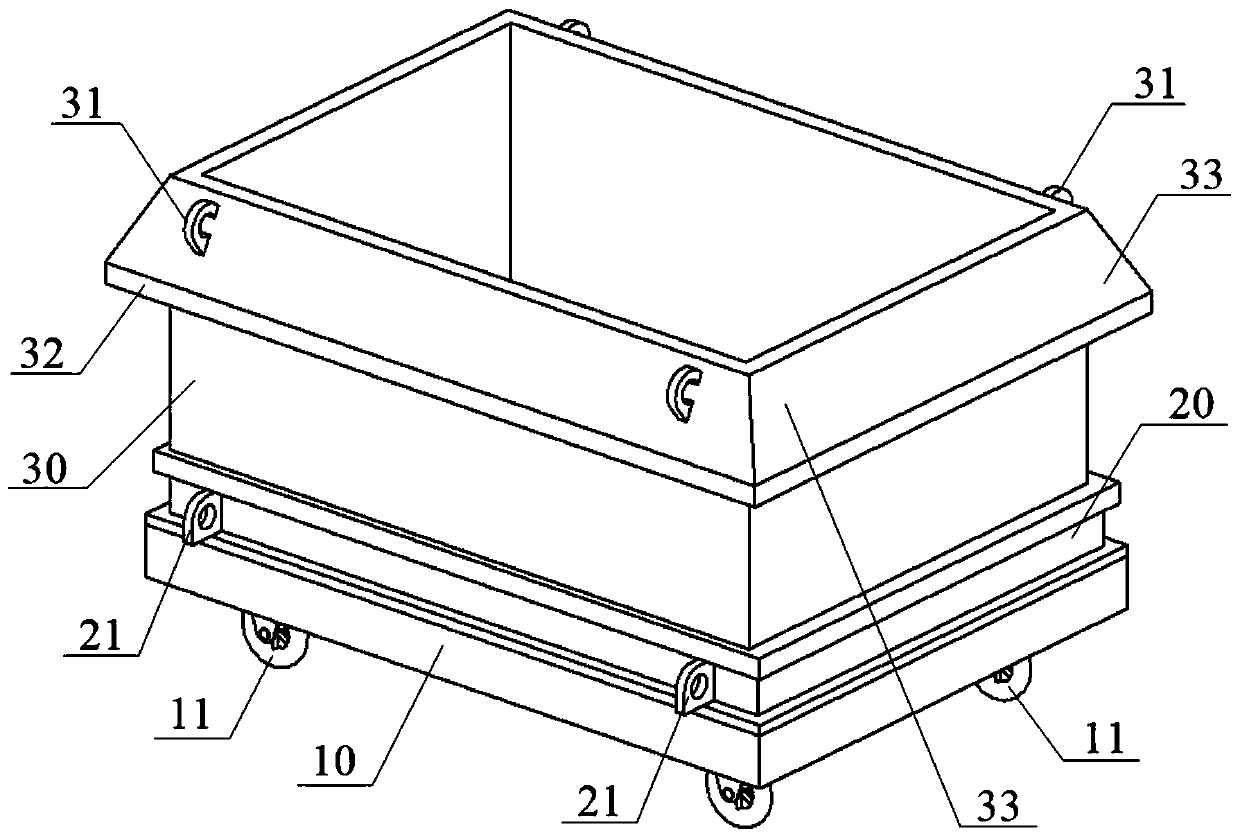

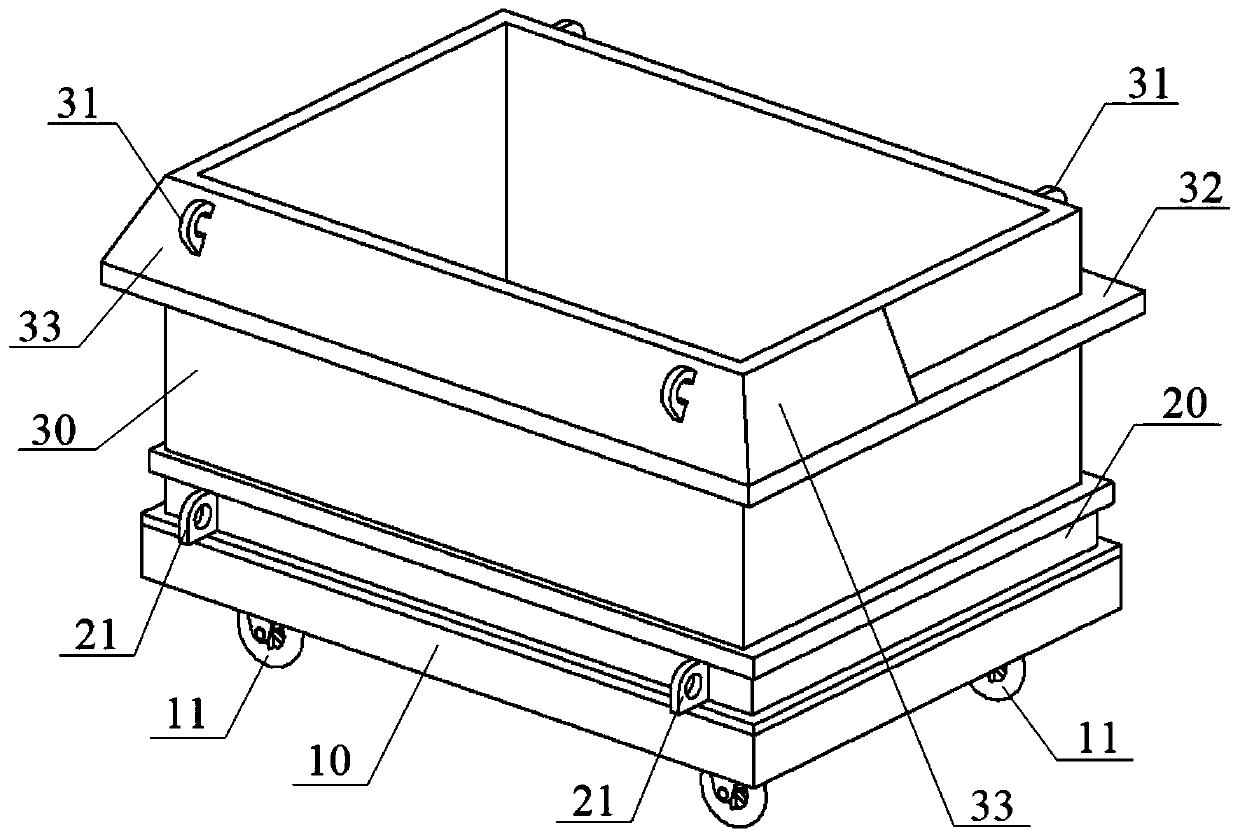

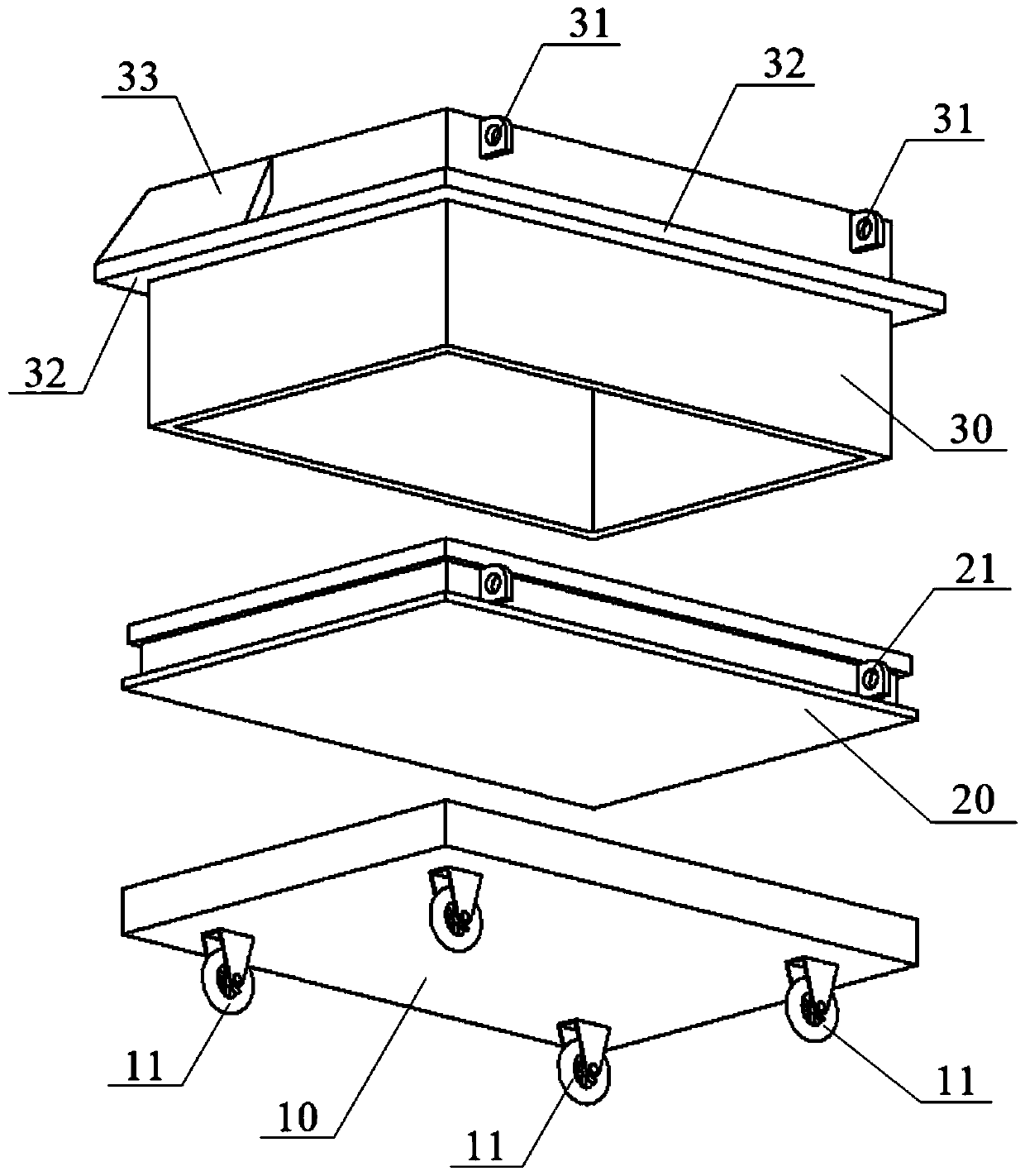

[0014] A slag transfer device, such as Figure 1-5 As shown, it includes a frame 10 and rollers 11 arranged below the frame 10. The frame 10 supports a pallet 20 and an enclosure frame 30, and the upper and lower open enclosure frames 30 are stacked on the pallet A cavity for holding slag is formed on 20. The pallet 20 constitutes the bottom of the cavity, and the surrounding frame 30 constitutes the peripheral side wall of the cavity. The pallet 20 and the enclosure frame 30 have a simple structure and are easy to clean, which can avoid the reduction of the slag capacity caused by the adhesion of slag to the slag, thereby improving the reuse rate of the pallet 20 and the enclosure frame 30.

[0015] When in use, the slag is poured into the cavity formed by the pallet 20 and the enclosure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com