Full-automatic cored pencil

A fully automatic, core-loading technology, used in mechanical pencils, printing, writing utensils, etc., can solve the problems of slow lead replacement, easy lead breakage, waste of time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

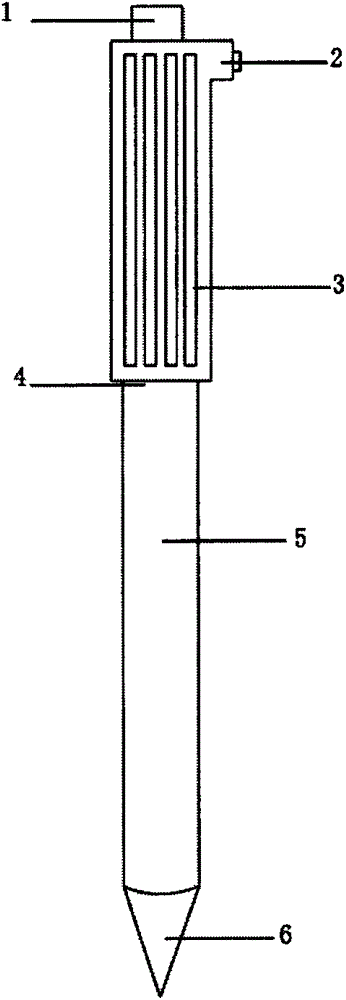

[0009] exist figure 1 In the embodiment shown, a lead-out button (1), a lead-down button (2), a lead core (3), a barrel body (4), a pen body (5), and a pen tip (6) are provided.

[0010] The fully automatic cored pencil implementing the present invention comprises a barrel body (4), characterized in that, the barrel body (4) is connected with a pen body (5), the pen body (5) is connected with a pen head (6), and the barrel body ( 4) A lead-out button (1) is installed on the top of the cylinder body (4), a lead-out button (2) is installed on the side of the cylinder body (4), and a lead core (3) is installed in the cylinder body (4).

[0011] The fully automatic cored pencil implementing the present invention is a fully automatic cored pencil. There are two buttons on the barrel body. When the lead is broken, press the lead button on the top, and the lead will automatically stretch out a section. When the lead is used up, press the lead button on the side, and a lead will come...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com