Skiing board produced by casting side wall

A technology for skis and side walls, which is used in the binding of snowboards and snowboards, skis, etc., can solve the problems of complex process, low production efficiency, easy to crash, etc. tracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The purpose, functions and advantages of the present invention will be further described with reference to the accompanying drawings in conjunction with the embodiments.

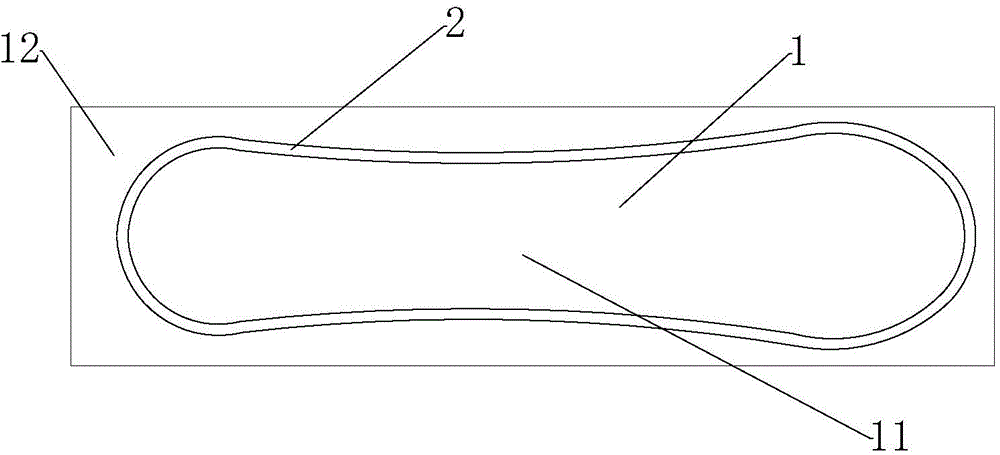

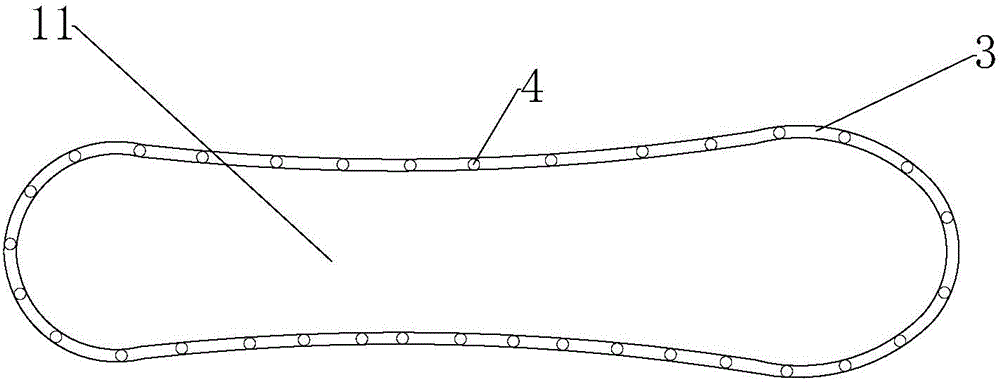

[0022] Such as figure 1 , figure 2 Shown, the concrete mode of operation of the present invention is:

[0023] First put the wooden core 1 on the platform, open a circle of groove 2 on the wooden core, remove the impurities in the groove 2, and then pour polyurethane into the groove 2 on the wooden core 1. It is necessary to add pigments of various colors to the polyurethane. If no pigment is added, it will be transparent or translucent. Heat and stir the polyurethane. You can also place LED lights 4, warning lights and other luminous objects in it, so that it can be used in case of accidents. When it is convenient to track or find the rescued in time, the LED lamp 4 can be a single-color lamp, a multi-color lamp or a variable-color lamp, and the strength of the side wall 3 can be adjusted as requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com