Intelligent industrial dust collector

An industrial vacuum cleaner and intelligent technology, applied in the installation of vacuum cleaners, electrical equipment, cleaning equipment, etc., can solve the problems of poor factory environment, inconvenient movement, low work efficiency, etc., and achieve a high degree of automation, high work efficiency, and intuitive observation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

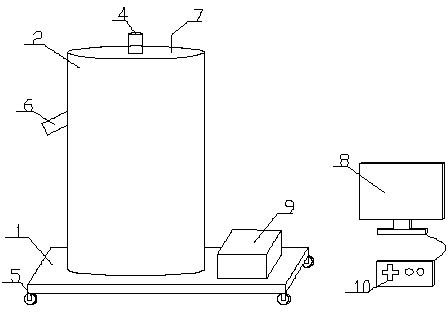

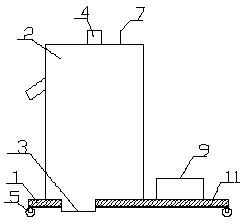

[0013] refer to figure 1 with figure 2 , an intelligent industrial vacuum cleaner in this embodiment can transmit the image in the factory building to the monitoring system through the probe provided at the front end of the cylinder, and the staff will send a signal to the receiving antenna through the control device connected to the monitoring system, and then The power device on the control bracket makes the industrial vacuum cleaner move to clean the dust and waste in the factory. The device is easy to operate and intuitive to observe. It does not need to consume a lot of physical strength of the workers. It has high work efficiency, is convenient to move, and has a high degree of automation. , including a bracket 1 and a cylinder 2 installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com