PTC heating device eliminating induced electricity

A heater and induction technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of high failure rate, poor thermal conductivity, low manufacturability, etc., to achieve increased thermal conductivity, reduced potential difference, and simple manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

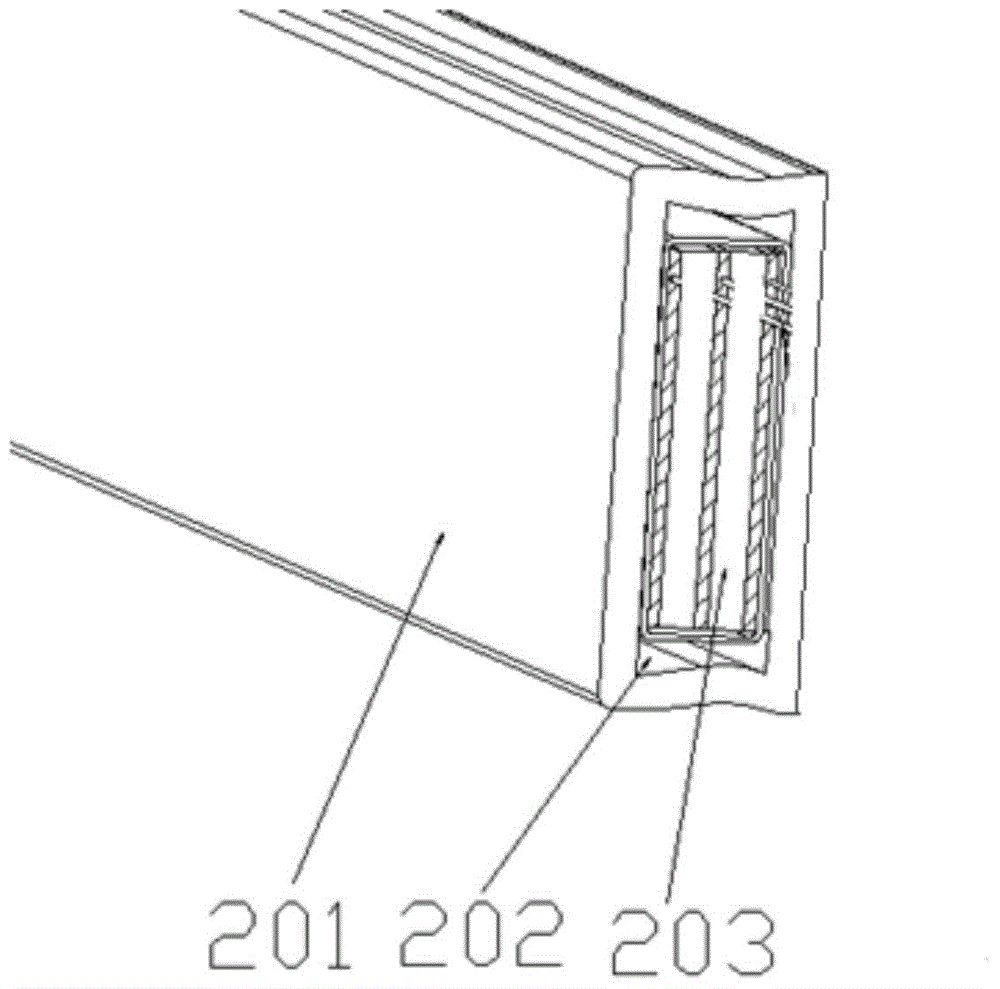

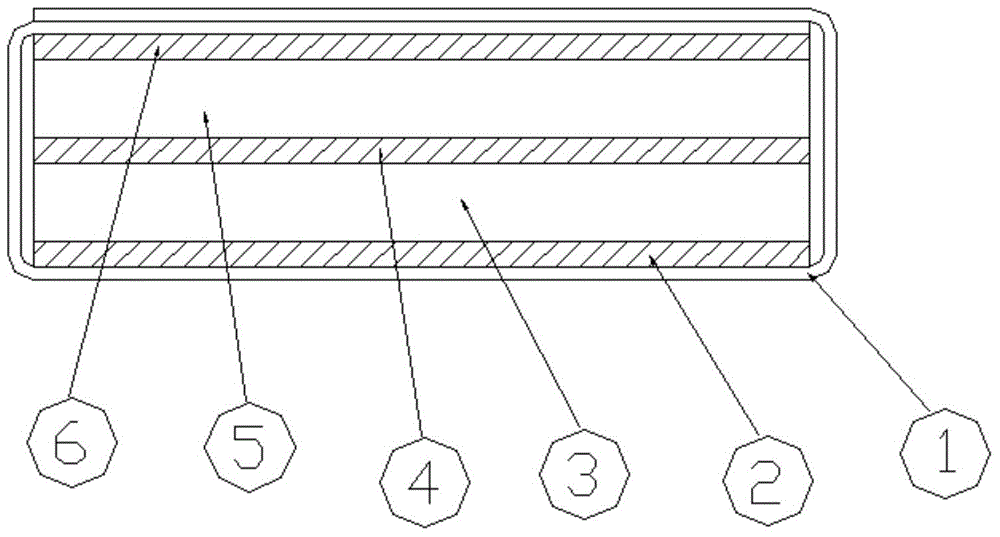

[0016] see figure 1 , a PTC heater device for eliminating induced electricity, comprising an aluminum heat sink 201, the aluminum heat sink is a hollow structure, and a heat dissipation inner cavity 202 is provided inside, and a PTC heating element 203 is arranged in the heat dissipation inner cavity 202, and the PTC heating element 203 includes The first electrode plate 2, the second electrode plate 4, the third electrode plate 6, the first ceramic heating sheet 3, the second ceramic heating sheet 5 and the insulating layer 1, and the first ceramic heating sheet 3 on both sides of the second electrode plate 4 And the second ceramic heating sheet 5, the outer side of the first ceramic heating sheet 3 is the first electrode plate 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com