3D manufacturing method for an electrode of an in-planeswitching blue phase liquid crystal display device

A technology of blue-phase liquid crystal and coplanar conversion, which is applied in instruments, electrical digital data processing, special data processing applications, etc., can solve the problems of difficult process and high cost, and achieve the effect of simple process, low cost and reduced driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

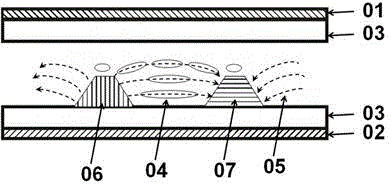

[0048] Such as Image 6 As shown, in this embodiment, when the protruding electrode is a thick electrode made of the same electrode material, the specific solution includes the following steps:

[0049] S1:Design and generate a three-dimensional digital model of the electrodes of the coplanar conversion blue-phase liquid crystal display device;

[0050] The three-dimensional model of the electrode can be established by three-dimensional CAD software (such as AUTO CAD, UG, Pro / Engineer, SolidWorks), or the workpiece sample can be scanned by CT (Computer Tomography), MRI (Magnetic Resonance Imaging), and then converted for a three-dimensional model. Preferably, in this embodiment, AUTO CAD software is used to establish a three-dimensional model. Preferably, in this embodiment, the cross-sectional figure of the electrode designed is trapezoidal. The width of the lower bottom of the electrode is 4 microns, the width of the upper bottom is 2 microns, and the height is 2 microns....

Embodiment 2

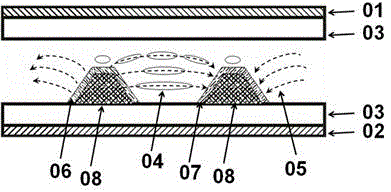

[0064] Such as Figure 7 As shown, in this embodiment, when the protruding electrodes are formed by spraying electrode materials on substrates of different materials, the specific scheme includes the following steps:

[0065] S1: Design and generate a three-dimensional digital model of the electrodes of the coplanar conversion blue-phase liquid crystal display device;

[0066] The three-dimensional model of the electrode substrate and electrode can be established by using three-dimensional CAD software (such as AUTO CAD, UG, Pro / Engineer, SolidWorks), or the workpiece sample can be scanned by CT (Computer Tomography), MRI (Magnetic Resonance Imaging), etc. , and then converted to a 3D model. Preferably, in this embodiment, AUTO CAD software is used to establish a three-dimensional model. Preferably, in this embodiment, the cross-sectional figure of the electrode designed is trapezoidal. The width of the lower bottom of the electrode base is 4 microns, the width of the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com