Fixing device of ultrasonic transducer for detecting quality of medium-small-sized concrete test block

A concrete test block and fixing device technology, which is used in measuring devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the fatigue of inspectors holding radial transducers, vertical Position deviation, waste of human resources and other problems, to achieve the effect of reducing the cost of ultrasonic testing, reducing testing errors, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The ultrasonic transducer fixing device for detecting the quality of small and medium-sized concrete test blocks of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

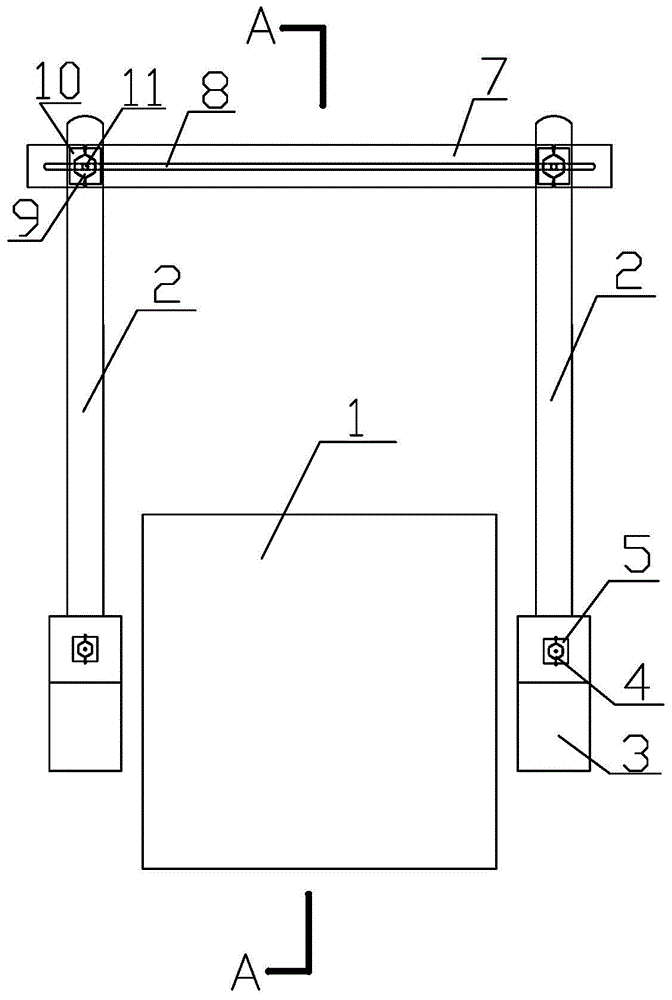

[0031] Such as figure 1 , figure 2 , image 3 As shown, the ultrasonic transducer fixing device for detecting the quality of small and medium-sized concrete test blocks of the present invention includes a horizontal connecting rod 7, two vertical connecting rods 2 and two ultrasonic transducers used for fixing ultrasonic testing. The transducer spring clip 3 of the energy device, wherein the top ends of the two vertical connecting rods 2 are respectively connected to the horizontal connecting rod 7, and are located on both sides of the tested concrete test block 1, and can Move horizontally along the horizontal connecting rod 7 , that is, the horizontal connecting rod 7 and the two vertical connecting rods 2 are vertical to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com