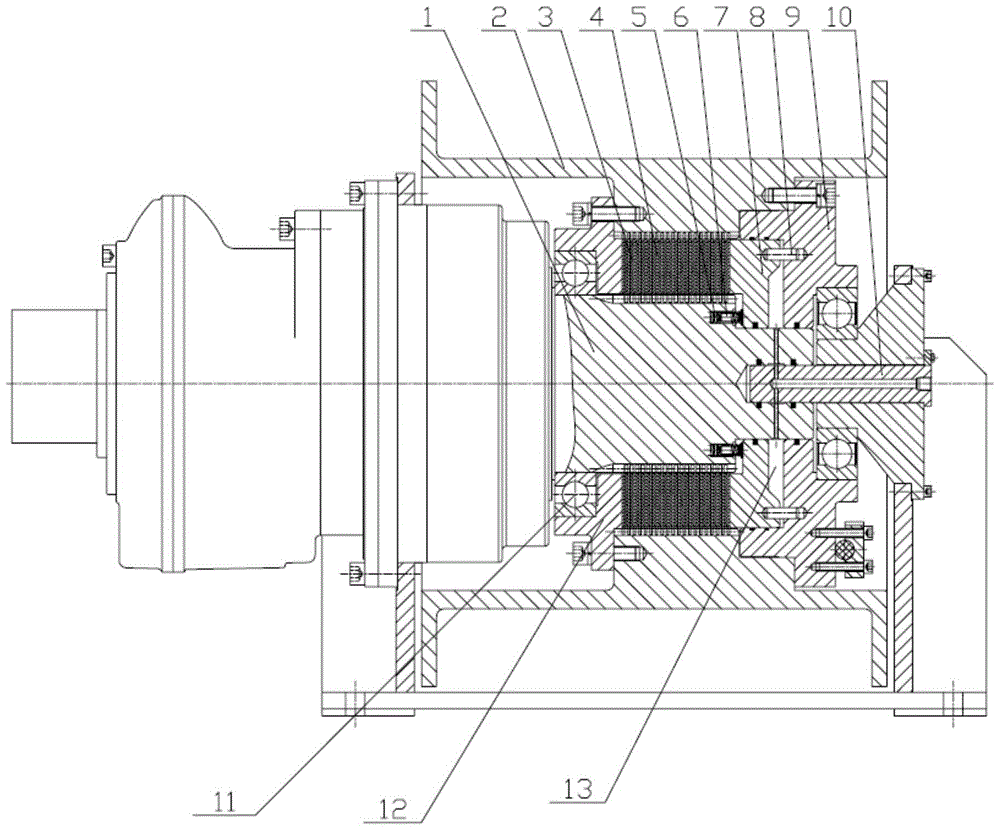

A winch clutch with wear compensation function and using method thereof

A wear compensation and clutch technology, used in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of insufficient pressing force, time-consuming and laborious, winch slippage, etc., and achieve a simple and reasonable structure, flexible control methods, and guaranteed reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

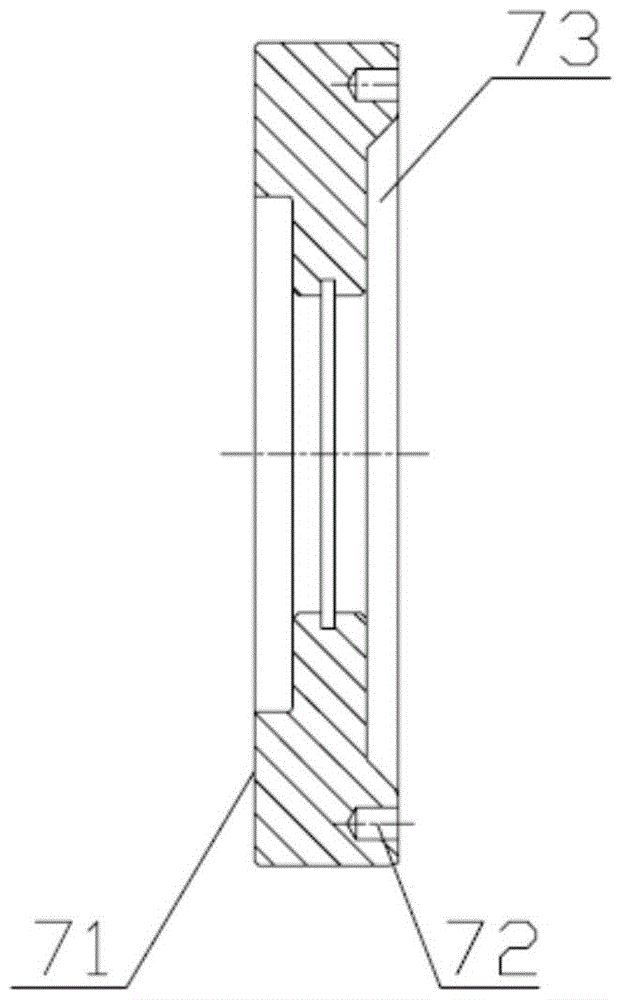

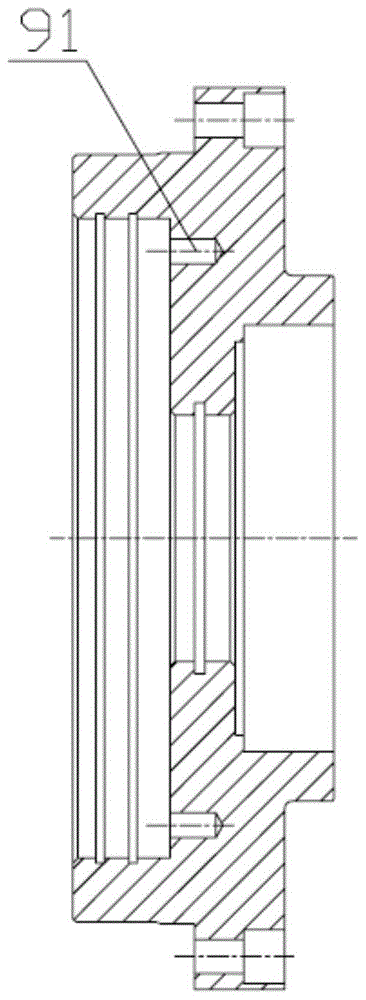

[0034] (a) Under normal conditions, the static friction plate 4 and the dynamic friction plate 3 are separated. When the external oil inlet channel inputs hydraulic oil into the pressurized space 13, the piston 7 is pushed along the shaft 1 of the reducer main shaft Move towards the static friction plate 4 or the dynamic friction plate 3 in the direction until the static friction plate 4 and the dynamic friction plate 3 are compressed, the static friction plate 4 and the dynamic friction plate 3 contact, and the rotation of the reducer main shaft 1 can drive the reel 2 to rotate;

[0035] (b) When the hydraulic oil in the pressurized space 13 is discharged, the piston 7 is restored under the action of the spring 5, the static friction plate 4 and the dynamic friction plate 3 are separated, and the reel 2 can rotate freely under the action of external force to act as a clutch;

[0036] (c) When the static friction plate 4 and the dynamic friction plate 3 are worn, the size of the wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com