Reusable assembled mixing station storage silo partition wall and construction method thereof

A mixing station and storage silo technology is applied to the storage silo partition wall of a prefabricated mixing station and its construction field. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

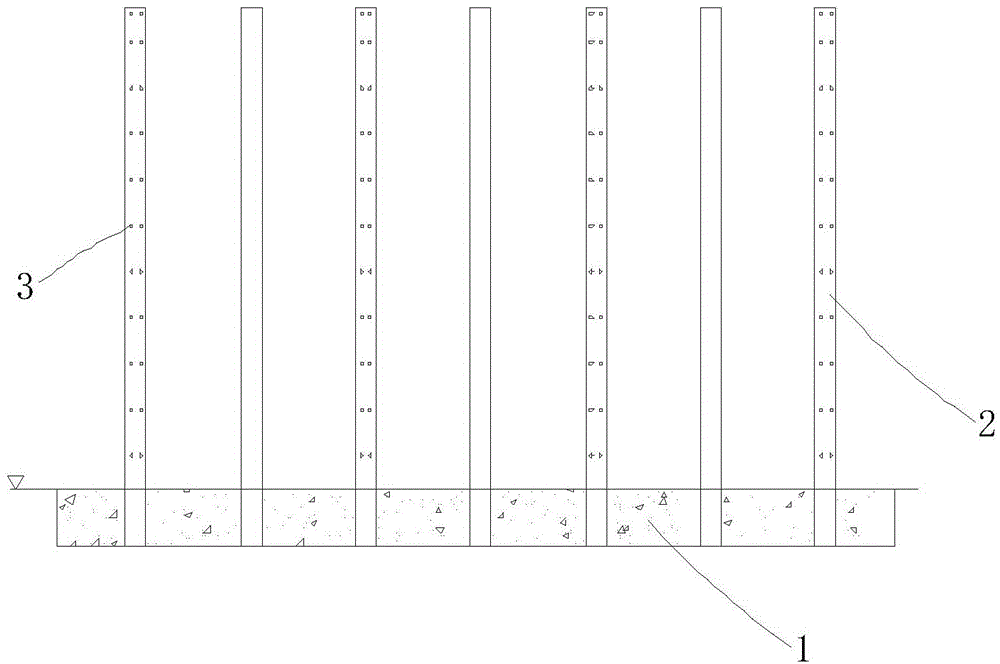

[0023] Embodiment: Referring to the accompanying drawings, the reusable prefabricated mixing station storage bin partition wall of this embodiment includes:

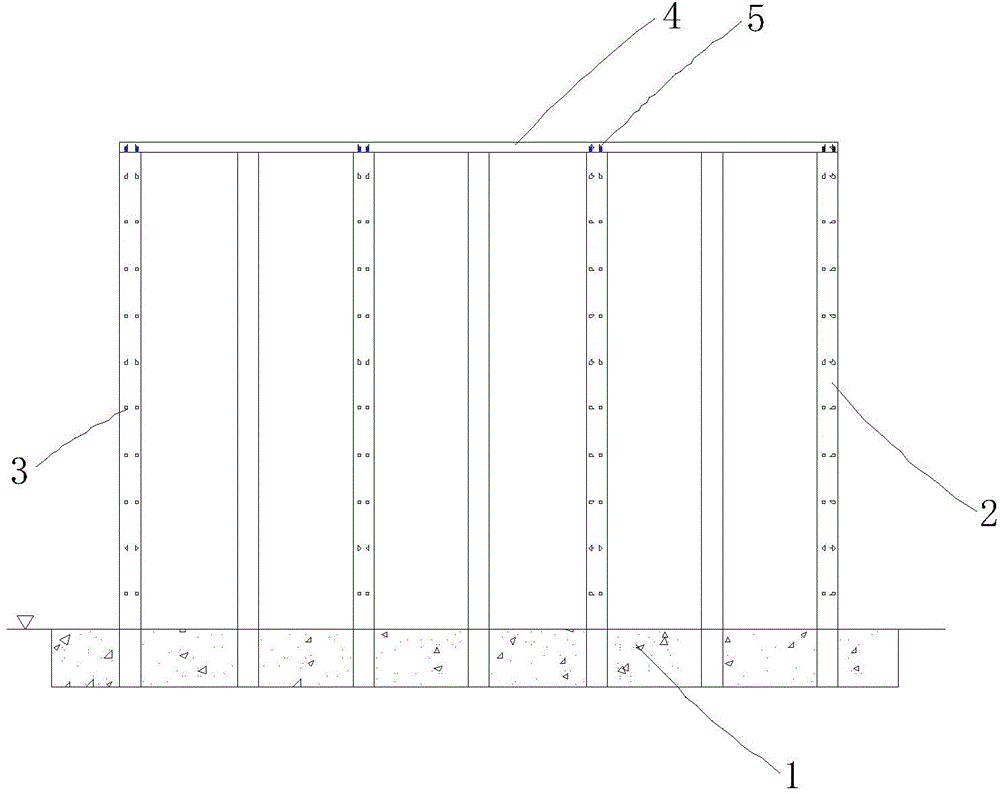

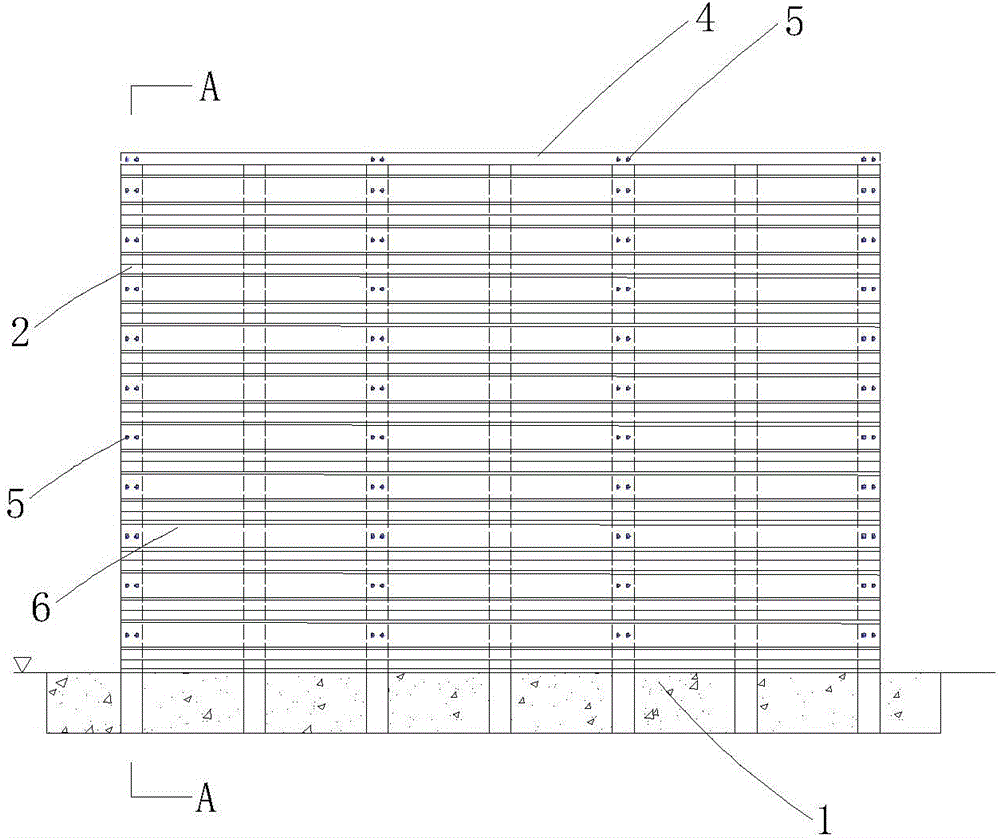

[0024] The concrete foundation 1 of the partition wall and the multiple I-steel columns 2 pre-buried on the concrete foundation 1, the multiple I-steel columns 2 are arranged at equal intervals in the length direction of the partition wall, and the multiple I-steel columns The top of the 2 is fastened with an inverted U-shaped steel plate 4 to cap, and both sides of a plurality of I-shaped steel columns 2 are fixed with corrugated steel plates 6 to form the inner and outer sides of the partition wall.

[0025] In the specific implementation, among the plurality of I-shaped steel columns 2, bolt holes 3 are preset on every other I-shaped steel, and the positions of the preset bolt holes 3 on the inverted U-shaped steel plate 4 are also preset according to the positions of the preset bolt holes 3 on the I-shaped steel. Bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com