A method for quantifying gas distribution in blast furnace throat

A blast furnace throat and furnace throat technology, which is applied in the field of quantifying blast furnace throat gas distribution, can solve problems such as unstable furnace operation, high gas utilization rate, and poor gas utilization, so as to reduce polluting gas emissions and improve utilization rate Level, the effect of improving the technical level of blast furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

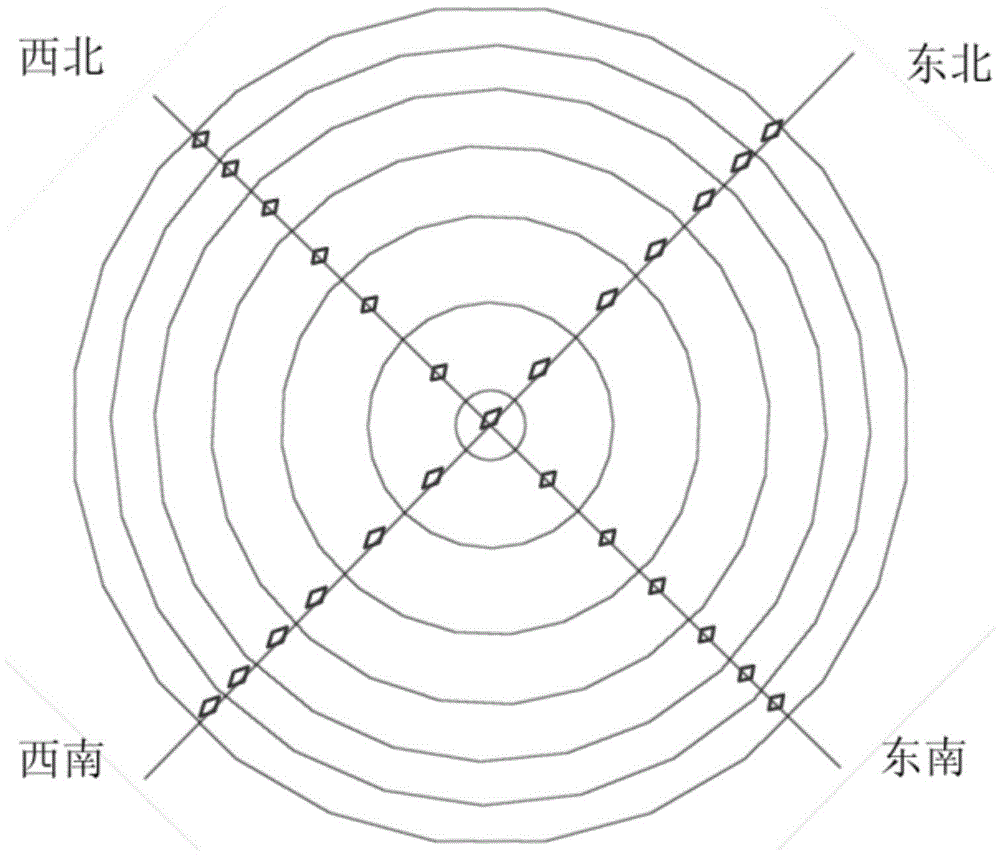

[0071] S1: See attached figure 1 , select the cross temperature measurement model with 7 thermocouples on the cross temperature measurement rod, the directions of the four cross temperature measurement rods are northwest, northeast, southwest and southeast respectively, and establish the furnace throat area according to the cross temperature measurement model airflow distribution model. At this time n=6, the furnace throat area is divided into a circular area GC and 6 annular areas (G1, G2, G3, G4, G5, G6)

[0072] S2: Determine the edge area in the airflow distribution model as G1, the platform area as (G2+G3+G4+G5) and the central area as (GC+G6).

[0073] S3: Calculate bosh gas volume, bosh gas volume = 1.21 x air volume + 2 x oxygen enrichment + humidity x 44.8 x (air volume + oxygen enrichment) / 18000 + coal injection x pulverized coal hydrogen content x 22.4 / 120 .

[0074] S4: Calculation of regional gas volume:

[0075] Regional gas volume WC of circular area GC, W...

Embodiment 2

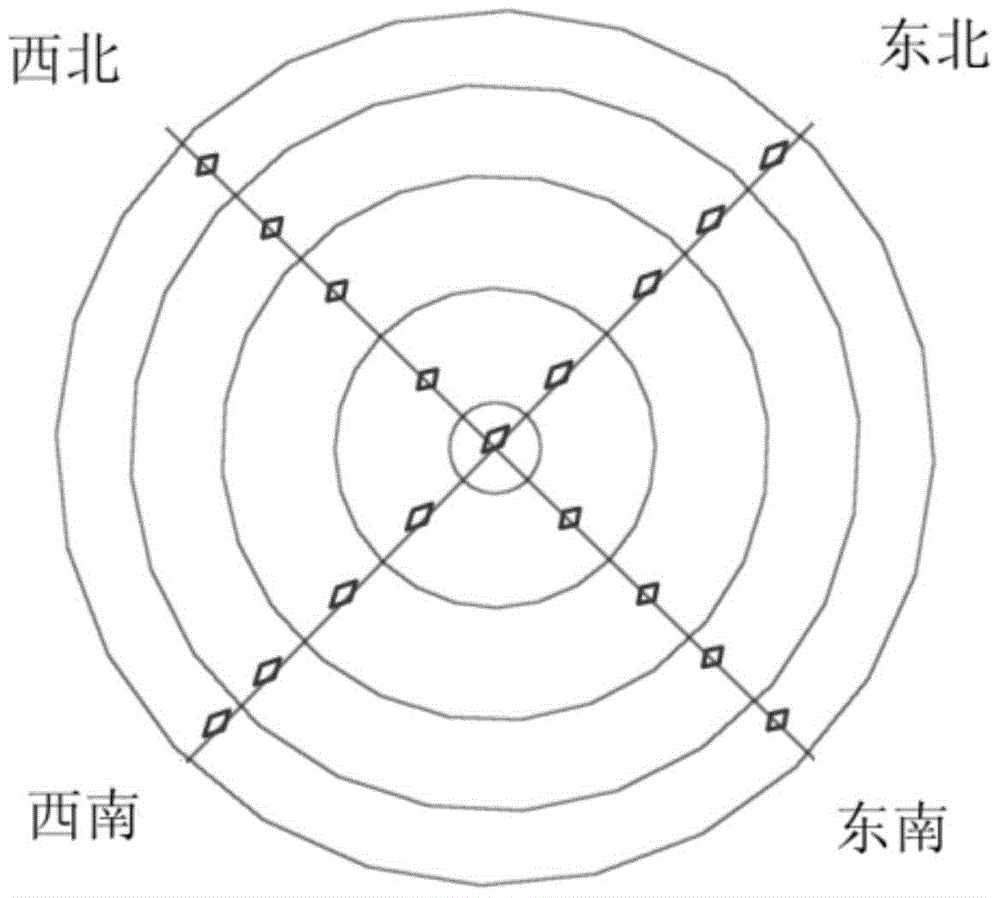

[0092] S1: See attached figure 2 , select the cross temperature measurement model with 5 thermocouples on the cross temperature measurement rod, the directions of the four cross temperature measurement rods are northwest, northeast, southwest and southeast respectively, and establish the furnace throat area according to the cross temperature measurement model airflow distribution model. At this time n=4, the furnace throat area is divided into a circular area GC and 4 annular areas (G1, G2, G3, G4)

[0093] S2: Determine the edge area in the airflow distribution model as G1, the platform area as (G2+G3) and the central area as (GC+G4).

[0094] S3: Calculate bosh gas volume, bosh gas volume = 1.21 x air volume + 2 x oxygen enrichment + humidity x 44.8 x (air volume + oxygen enrichment) / 18000 + coal injection x pulverized coal hydrogen content x 22.4 / 120 .

[0095] S4: Calculation of regional gas volume:

[0096] Regional gas volume WC of circular area GC, WC=bosh gas volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com