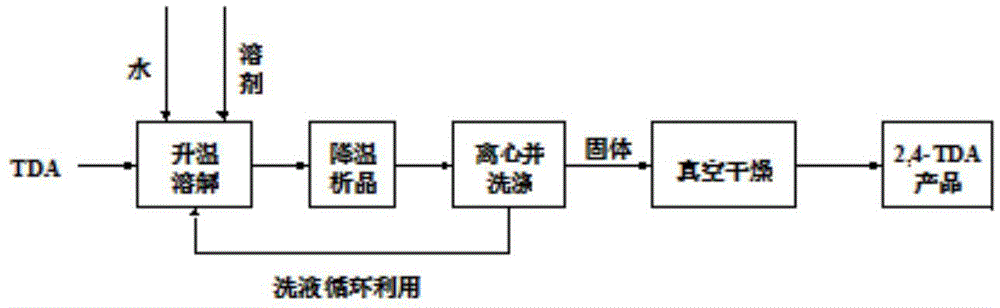

Technology for purifying 2, 4-diaminotoluene by recrystallization method

A technology of diaminotoluene and recrystallization, applied in the direction of amino compound purification/separation, organic chemistry, etc., can solve the problems of environmental pollution, serious environmental pollution, a large amount of acidic wastewater, waste residue, etc., to avoid secondary pollution, process and device Simple, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

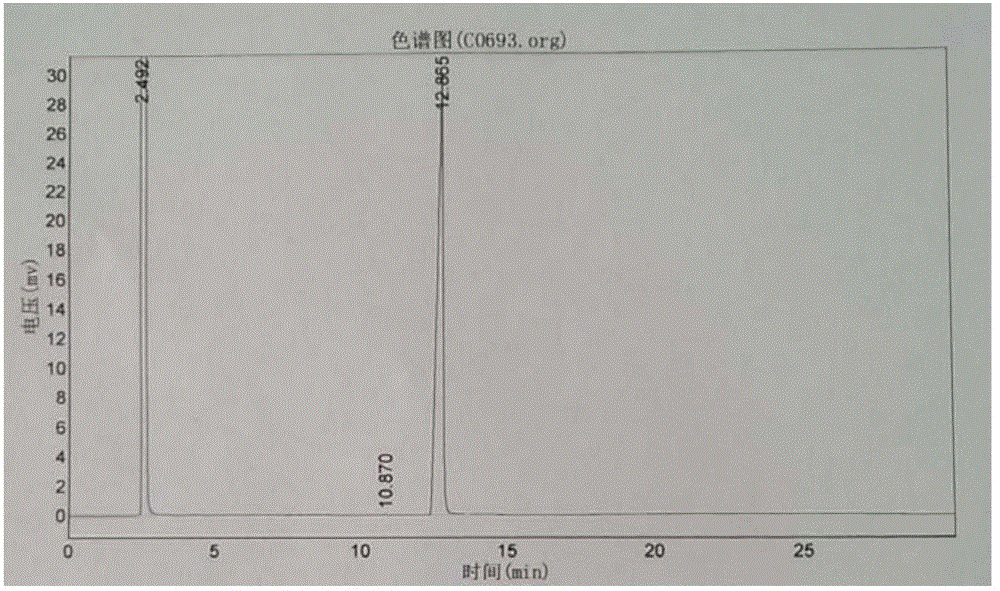

[0034] Add 1000kg of 2,4 and 2,6-diaminotoluene mixture (isomerization ratio 2,4 / 2,6=(80±5) / (20±5)), 500kg of distilled water and 500kg of methanol into the reactor, Stir while heating, and reflux at a temperature of 65°C to dissolve and mix the above materials evenly; stop heating, cool down to 10-15°C with water through the jacket of the crystallizer, and precipitate crystals; separate with a centrifuge, and obtain The crystals were washed and separated with water, and the washed crystals were vacuum-dried at 65-75°C with a vacuum degree greater than 0.080MPa to obtain 600kg of 2,4-diaminotoluene with a yield of 60% (relative to 2,4 and 2,6-diaminotoluene mixture), the purity of the product (detected by gas chromatography (GC method)) is 99.78% (see figure 2 ). The washing liquid separated by centrifugation is returned to the reaction kettle through the liquid pump as raw material for recycling.

Embodiment 2

[0036] Add 1000kg of 2,4 and 2,6-diaminotoluene mixture (isomerization ratio 2,4 / 2,6=(80±5) / (20±5)), 1500kg of distilled water and 1500kg of ethanol into the reactor, Introduce nitrogen for protection, stir while heating, and dissolve and mix the above materials evenly under the reflux state of 50°C; stop heating, cool down to 10-15°C with water through the jacket of the reaction kettle, and stir to precipitate crystals; Separation, washing the crystals obtained after separation with water, separation, vacuum-drying the washed crystals at 65-75°C, the vacuum degree is greater than 0.080MPa, to obtain 580Kg of 2,4-diaminotoluene, the yield is 58% , the purity (GC method) of the product is 99.72%. The washing liquid separated by centrifugation is returned to the reaction kettle through the liquid pump as raw material for recycling.

Embodiment 3

[0038] Add 500g of 2,4 and 2,6-diaminotoluene mixture (isomerization ratio 2,4 / 2,6=(80±5) / (20±5)), 500g of distilled water and 500g of ethylene glycol into the reactor In the process, pass nitrogen protection, stir while heating, dissolve and mix the above materials evenly at a temperature of 85°C; stop heating, pass through the crystallizer jacket, cool down with water by 10-15°C, stir and precipitate crystals; use a centrifuge to separate , washing the crystals obtained after separation with water, separating, and vacuum-drying the washed crystals at 65-75° C., with a vacuum degree greater than 0.080 MPa, to obtain 325 g of 2,4-diaminotoluene with a yield of 65%. The purity of the product (GC method) is 99.57%; the washing liquid separated by centrifugation is used as raw material for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com