Composite modified high titanium slag micropowder used for concrete and concrete preparation method

A high-titanium slag, compound modification technology, applied in climate sustainability, sustainable waste treatment, solid waste management and other directions, can solve the problem of difficult to meet the requirements of S75 grade slag powder, reduce the strength of cement concrete, high titanium slag is easy to grind It can improve the performance of the product, improve the shrinkage of concrete, and reduce the porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

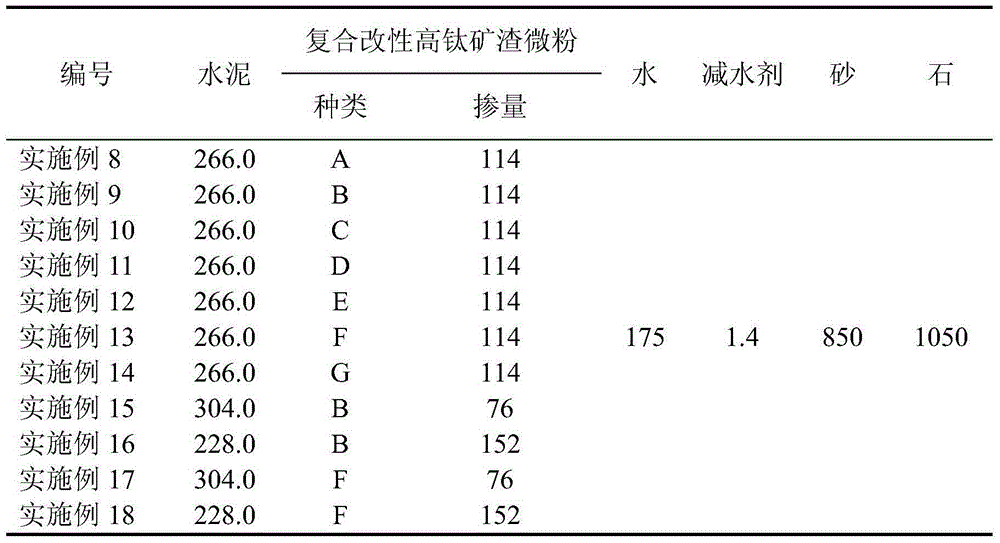

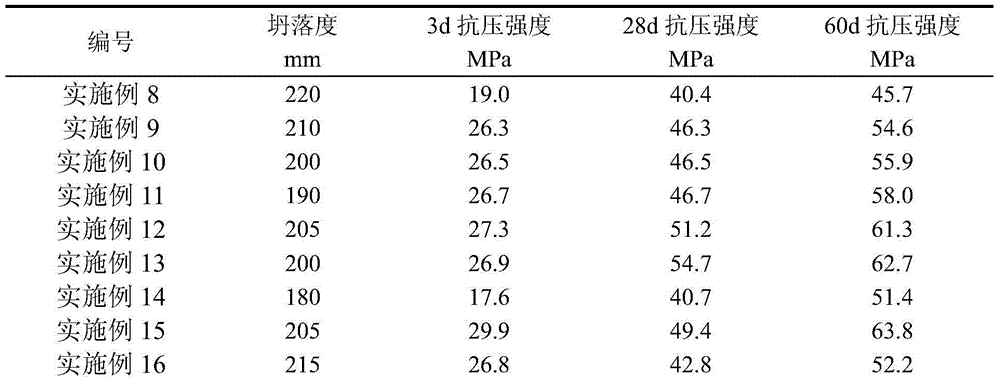

Examples

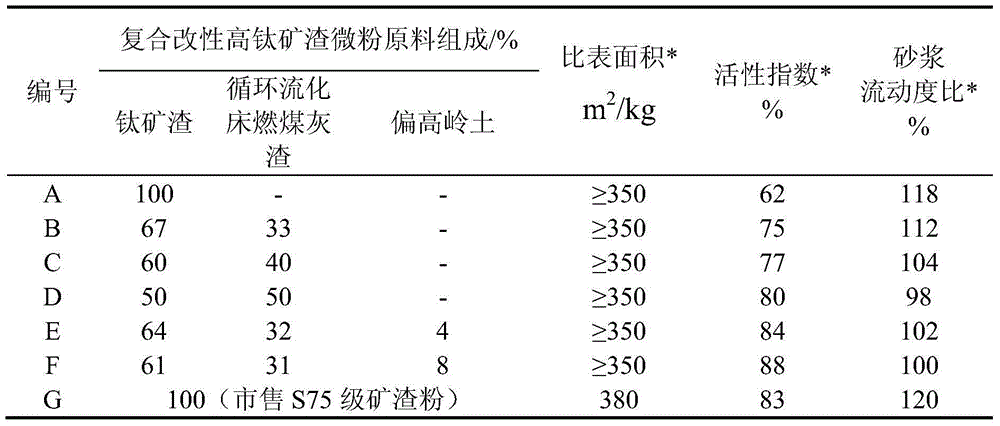

Embodiment 1

[0032] The high-titanium slag is not subjected to compound modification, and the high-titanium slag micropowder A is prepared, and the specific surface area is ≥350m 2 / kg, 28d activity index 62%, mortar fluidity ratio 118%.

Embodiment 2

[0034] Composite modified high-titanium slag powder B is prepared from 67% by weight of titanium slag and 33% by weight of circulating fluidized bed coal ash, with a specific surface area ≥ 350m 2 / kg, 28d activity index 75%, mortar fluidity ratio 112%.

Embodiment 3

[0036] Composite modified high-titanium slag micropowder C is prepared from 60% by weight of titanium slag and 40% by weight of circulating fluidized bed coal ash, with a specific surface area ≥ 350m 2 / kg, 28d activity index 77%, mortar fluidity ratio 104%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com