Coil package material automatic following device

A technology of packaging materials and splicing devices, which is applied in the directions of winding strips, transportation and packaging, and thin material processing, can solve the problems of reducing the production efficiency of packaging machines, increasing working hours, and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

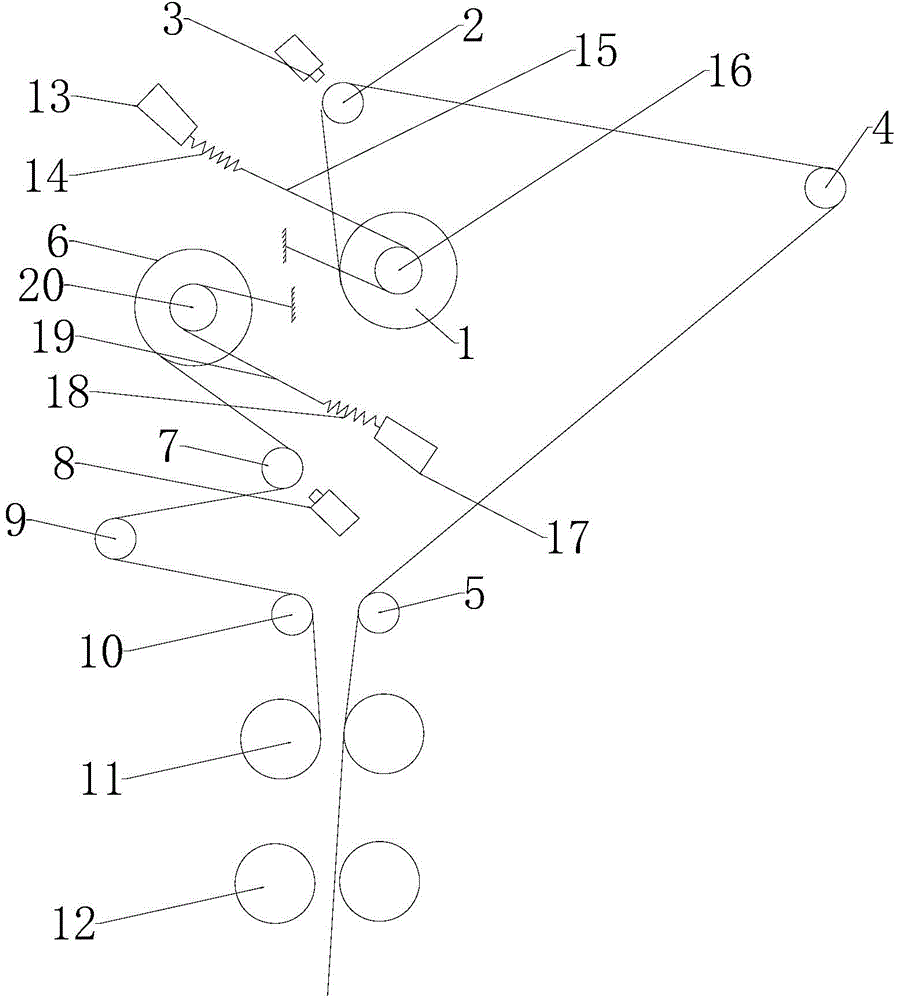

[0011] Depend on figure 1 It is known that an automatic splicing device for tape and tape packaging materials includes a coiled material disk 1, a first tension roller 2, a first proximity switch 3, a first guide roller 4, a second guide roller 5, a coiled material disk 6, a second The tension roller 7, the second proximity switch 8, the third guide roller 9, the fourth guide roller 10, the sheet changing nip roller 11 and the traction roller 12, the end of the sheet on the coil disk 1 passes through the first Tight roller 2, the first guide roller 4, the second guide roller 5 to the traction roller 12, the end of the sheet on the coiled material disk 6 passes through the second tension roller 7, the third guide roller 9, the fourth From the guide roller 10 to the sheet changing nip roller 11, the first proximity switch 3 is arranged near the first tension roller 2, and the second proximity switch 8 is arranged near the second tension roller 7. A first brake device is set at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com