Automatic feeding device of plunger piston core of automobile fuel injection pump

A technology of automatic feeding and fuel injection pump, which is applied to vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of low feeding accuracy and speed, reverse direction of the plunger, safety hazards, etc., and achieves simple and compact structure. Easy placement and long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

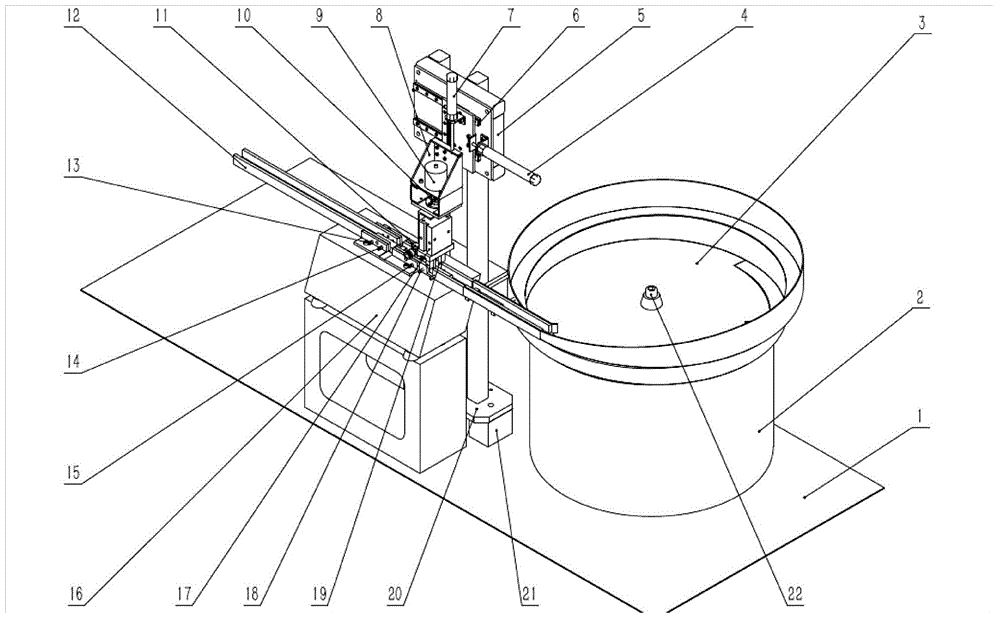

[0030] Such as Figure 1 to Figure 9 As shown, the present invention is an automatic feeding device for the plunger core of an automobile fuel injection pump. detection device. The spiral round material tray 3 is connected and fixed to the circular vibrating base 2 through connecting bolts 22, and the regular vibration of the vibrating base 2 is transmitted to the spiral circular material tray 3, thereby driving the plunger core in the spiral circular material tray 3 to move along the Tray rail transport and alignment. The spiral round material tray 3 is provided with a height limiting device 25 and a width limiting gap 26, which can ensure that the plunger cores will not overlap or be juxtaposed during vibration transmission and arrangement in the material tray 3, so that the plunger cores can be moved from the discharge end. The single row is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com