Paper slip sealing machine for paper box

A technology of sealing machine and paper strip, applied in the directions of packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of environmental pollution, difficulty in reusing plastic tapes, and high recycling costs, and achieve convenient use, manpower saving, The effect of reducing the cost of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

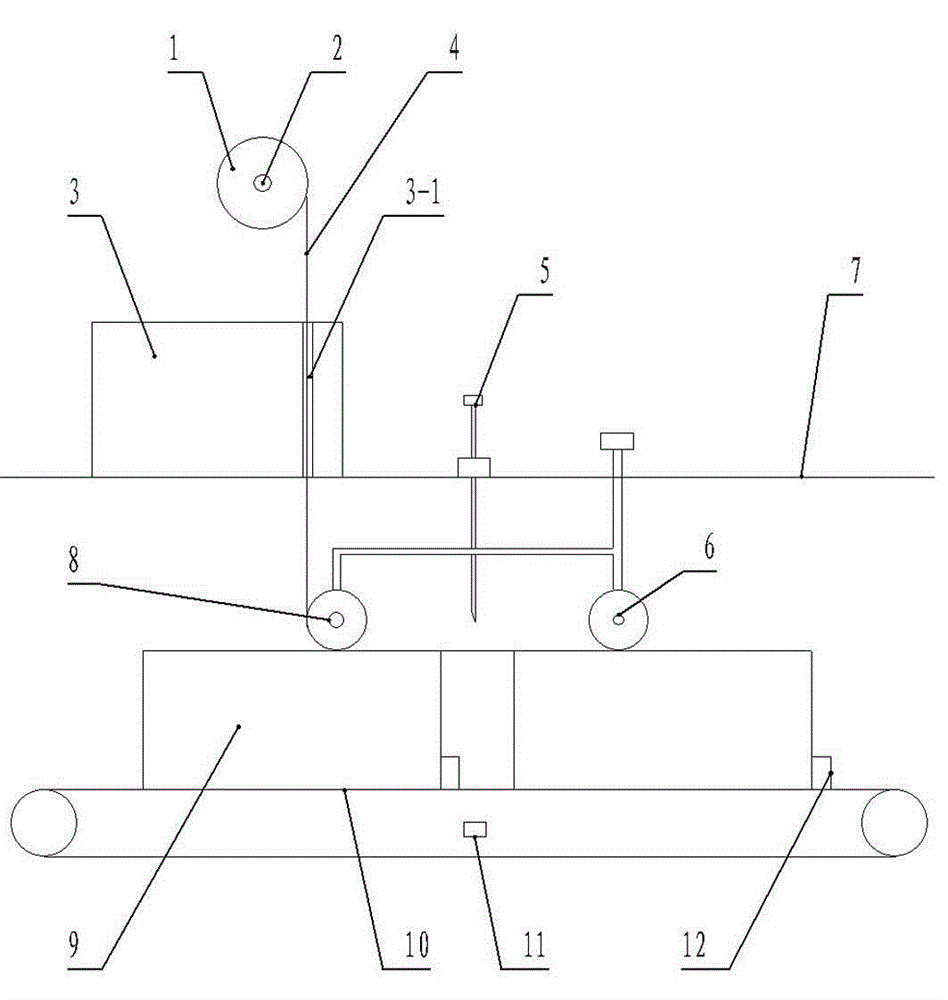

[0013] figure 1 The shown carton paper strip sealing machine includes a conveyor belt 10 provided with a carton positioning adjustment block 12, and a paper strip delivery device is provided above the conveyor belt 10. The paper strip delivery device includes a controller (not shown in the figure), a support 7 , the glue storage box 3 installed on the support 7, the side of the glue storage box 3 is provided with a glue outflow groove 3-1, the top of the glue storage box 3 is provided with a hanging rod 2 for placing the paper roll 1, and the paper strip 4 of the paper roll 1 The notch close to the glue outflow groove 3-1 runs through the glue storage box 3 and then bypasses the guide roller 8 to fit the seal of the carton 9 on the conveyor belt 10. Roller 6, pressure roller 6 and guide roller 8 are fixedly connected and can be adjusted up and down, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com