Electrically heated automobile windshield glass

A windshield, electric heating technology, applied in the direction of windshield, vehicle parts, windows, etc., can solve the problems of easy cracking and uneven heating of glass, and achieve the effect of improving rear view, uniform heating, and easy thermal bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

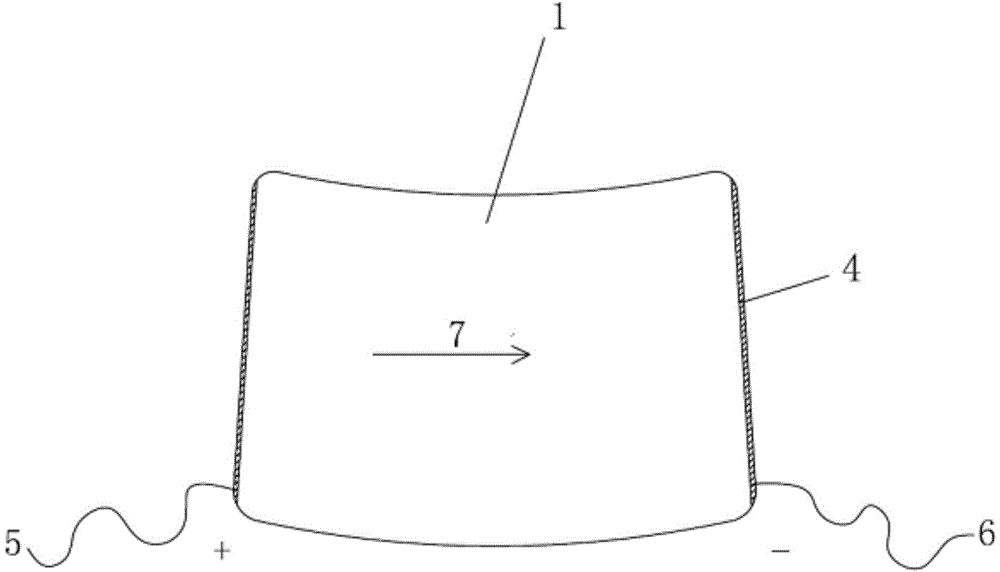

[0046] This embodiment discloses an electric heating automobile windshield, such as figure 1 As shown, it is a layer of FTO conductive glass substrate, electrodes are printed or pasted on the edges of the left and right sides of the FTO conductive glass substrate, and the electrodes are electrically connected to the power supply. The FTO conductive glass substrate is a float glass substrate deposited with an FTO conductive film, and the FTO conductive film is a transparent conductive layer of tin oxide doped with fluorine. The thickness of the FTO conductive glass substrate is: 20mm, and the thickness of the FTO conductive film is: 1000nm. The sheet resistance of the FTO conductive glass substrate is: 7ohm / □(7ohm / sq). The electrodes are conductive film silver bars. The power applied to the electrodes was 36V. The current direction 7 is indicated by the arrow.

[0047] The preparation method of electric heating automobile windshield of the present embodiment comprises the fo...

Embodiment 2

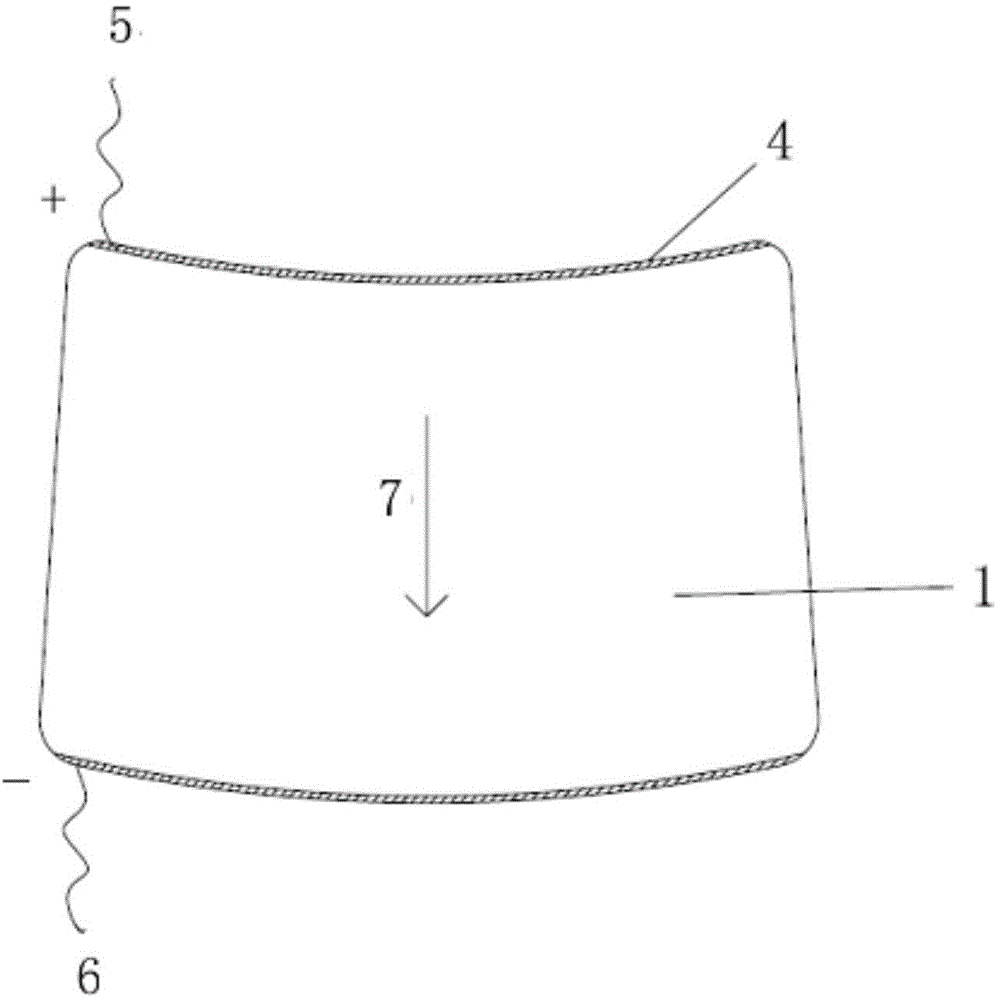

[0053] This embodiment discloses an electric heating automobile windshield, such as figure 2 As shown, it is a layer of FTO conductive glass substrate, electrodes are printed or pasted on the upper and lower edges of the FTO conductive glass substrate, and the electrodes are electrically connected to the power supply. The FTO conductive glass substrate is a borosilicate glass substrate deposited with an FTO conductive thin film. FTO is a transparent conductive layer of tin oxide doped with fluorine. The thickness of the FTO conductive glass substrate is: 2mm, and the thickness of the FTO conductive film is: 50nm. The sheet resistance of the FTO conductive glass substrate is: 7ohm / □ (7ohm / sq). The electrodes are conductive strips, conductive films or conductive glue. The power applied to the electrodes was 24V. The current direction 7 is indicated by the arrow.

[0054] The preparation method of electric heating automobile windshield of the present embodiment comprises the...

Embodiment 3

[0060] This embodiment discloses an electric heating automobile windshield, such as image 3 As shown, it is a layer of FTO conductive glass substrate, electrodes are printed or pasted on the edges of the left and right sides of the FTO conductive glass substrate, and the electrodes are electrically connected to the power supply. The FTO conductive glass substrate is a float glass substrate deposited with an FTO conductive thin film. FTO is a transparent conductive layer of tin oxide doped with fluorine. The thickness of the FTO conductive glass substrate is: 10mm, and the thickness of the FTO conductive film is: 100nm. The sheet resistance of the FTO conductive glass substrate is: 7ohm / □(7ohm / sq). The electrodes are conductive strips, conductive films or conductive glue. The power applied to the electrodes was 24V. The current direction 7 is indicated by the arrow.

[0061] The preparation method of electric heating automobile windshield of the present embodiment comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com