A multi-stage elliptical solid-liquid separator

A solid-liquid separator and elliptical stacking technology, which is applied in the direction of presses, manufacturing tools, etc., can solve the problems of low dehydration rate of processed objects, water discharge of processed objects, difficult water discharge, etc., and achieve energy saving, transportation efficiency and drainage efficiency The effect of lifting and improving the dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

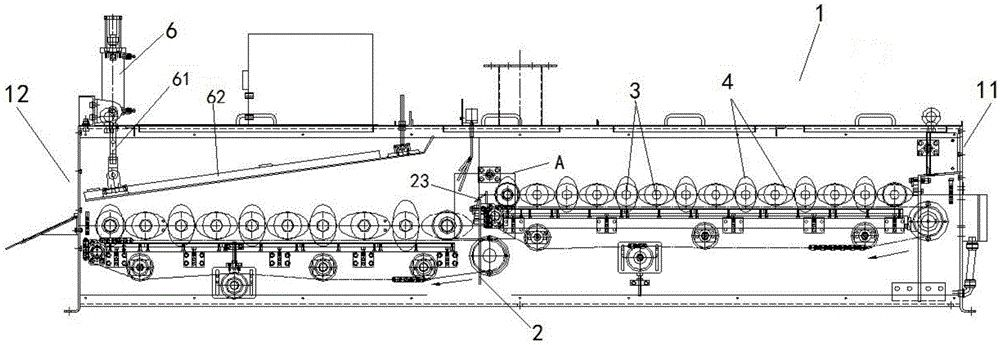

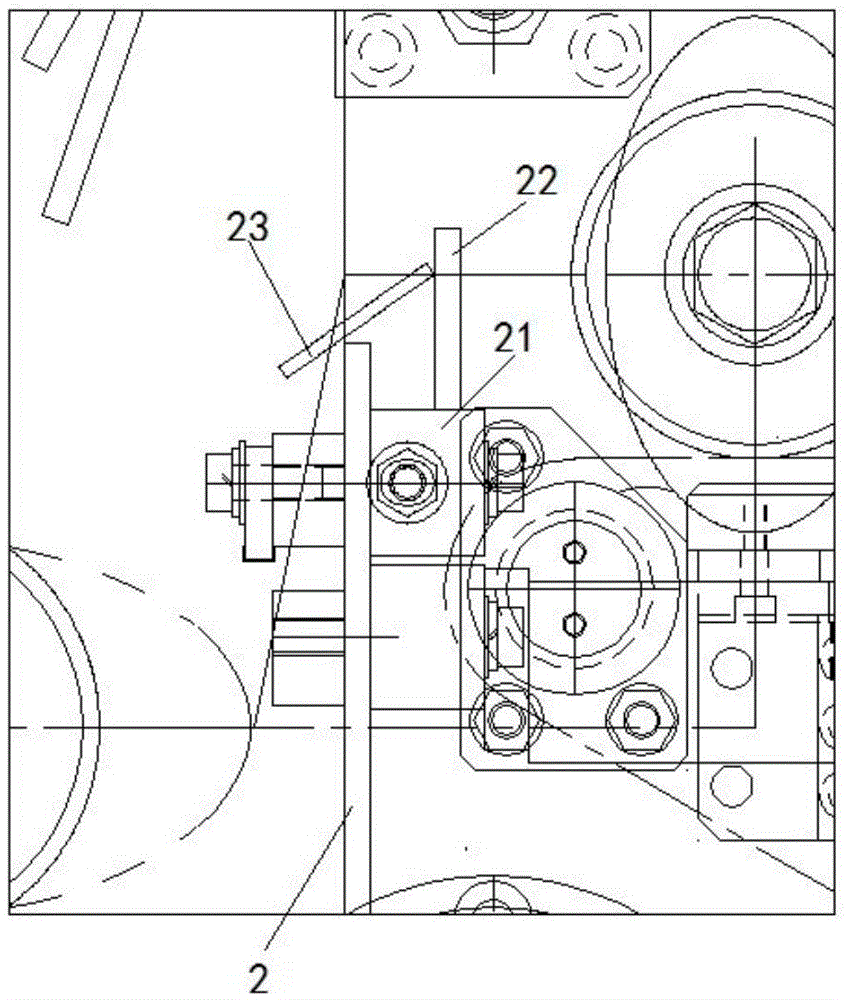

[0053] This embodiment provides a multi-stage elliptical solid-liquid separator, such as Figure 1-2 As shown, it includes a cabinet 1 with a processing object input port 11 and an output port 12, and a multi-stage carrying surface connected to the above-mentioned input port 11 and output port 12 arranged in the cabinet 1, and the processing object is carried from the front stage to the rear stage. The surface direction is transported longitudinally, and the terrain at the end of the front-stage carrying surface is higher than that at the head of the rear-stage carrying surface to form a terrain difference, and a guiding structure is set between adjacent two-stage carrying surfaces. The treated matter to be separated from solid and liquid enters the multi-stage elliptical solid-liquid separator from the input port 11, and is successively carried and transported by the multi-stage carrying surface to the output port 12 for output. During the transportation process, the treated m...

Embodiment 2

[0075] This embodiment provides a multi-stage elliptical solid-liquid separator, which is a deformation on the basis of Embodiment 1. It also includes two-stage carrying surfaces. The difference lies in the original solid-liquid ratio of the processed object and other data parameters related thereto Changes: In this embodiment, as shown in Table 1, the original solid-liquid ratio of the processed object is 7:4, the effective dehydration length of the first-stage carrying surface is 1320 mm, and the eccentricity of the rotary plate 4 located on the first-stage carrying surface is 0.9, the semi-major axis length of the revolving plate 4 is 90 mm, the thickness h1 of the revolving plate 4 is 3 mm, and the gap distance between two adjacent revolving plates 4 forming the revolving plate row is 9 mm, the The distance between adjacent rotary plates 4 is 2 mm, the rotation speed of the rotary shaft 3 is 20 rpm; the effective dehydration length of the second-stage carrying surface is 12...

Embodiment 3

[0077]This embodiment provides a multi-stage elliptical solid-liquid separator, which is a deformation on the basis of Embodiment 1. It also includes two-stage carrying surfaces. The difference lies in the original solid-liquid ratio of the processed object and other data parameters related to it Changes: In this embodiment, as shown in Table 1, the original solid-liquid ratio of the processed object is 3:2, the effective dehydration length of the first-stage carrying surface is 1360mm, and the eccentricity of the rotary plate 4 located on the first-stage carrying surface is 0.7, the semi-major axis length of the rotary plate 4 is 80 mm, the thickness h1 of the rotary plate 4 is 5 mm, and the gap distance between two adjacent rotary plates 4 forming the rotary plate column is 8 mm, and the The distance between adjacent rotary plates 4 is 8 mm, the rotation speed of the rotary shaft 3 is 30 rpm; the effective dehydration length of the second-stage carrying surface is 1240 mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com