Continuous centring pre-heating and egg-boiling integrated machine

An all-in-one machine and centering mechanism technology, applied in the field of poultry and egg processing, can solve the problems of high production cost, unfavorable maintenance and operation, and large occupied space, etc., to achieve small occupied area, facilitate maintenance and operation, and save land occupation effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

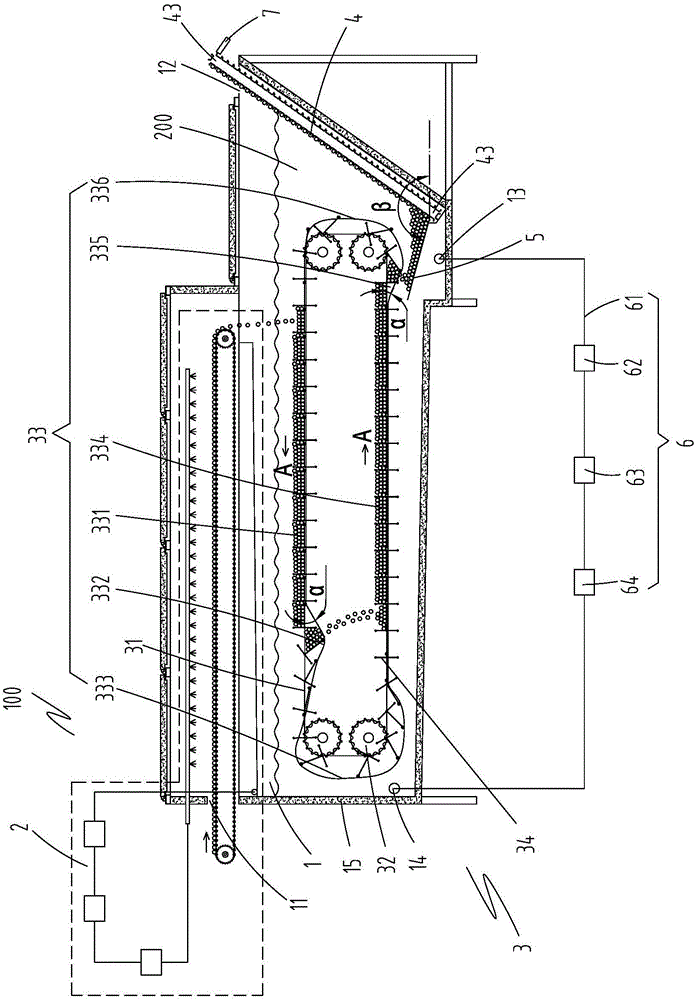

[0025] Please refer to Figure 1 to Figure 6 :

[0026] The continuous centering, preheating and egg cooking integrated machine 100 of the present invention includes a body 1 filled with water for boiling eggs, a preheating rotating centering mechanism 2 located in the body 1, and a body 1 for boiling water. The egg-boiling device 3 in 200, and a boiled egg lifting mechanism 4; the body 1 is provided with an egg inlet 11 and an egg outlet 12, and the egg inlet 11, the egg outlet 12, and the preheating rotating The centering mechanisms 2 are all located above the water surface of the egg-boiling water 200 , the preheating rotating centering mechanism 2 is connected to the egg inlet 11 , and the boiled egg lifting mechanism 4 is obliquely installed on the body 1 .

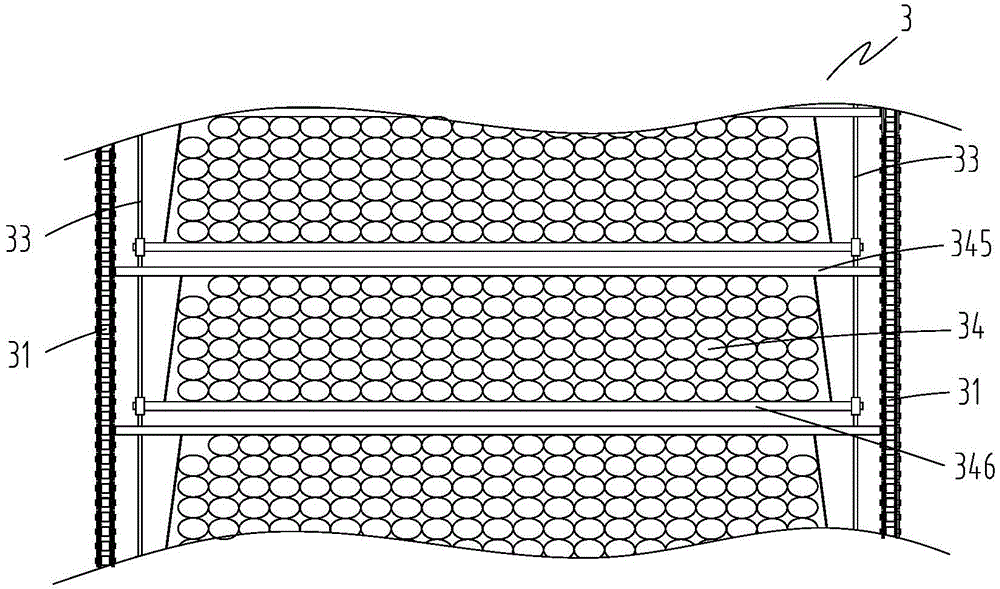

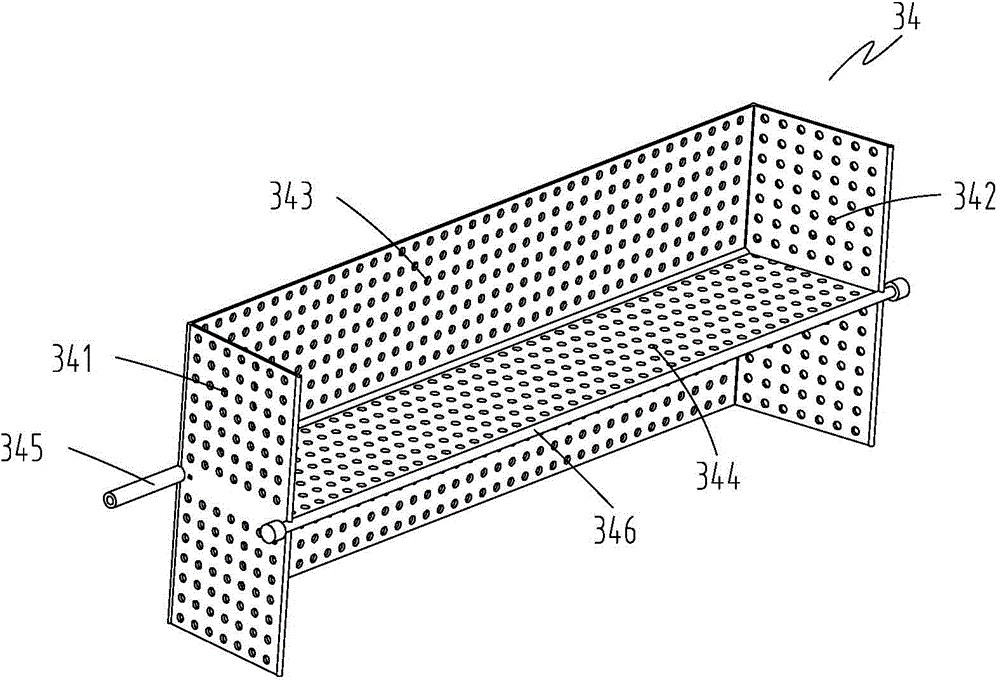

[0027] The egg-boiling device 3 is located directly below the preheating rotating centering mechanism 2, and the egg-boiling device 3 includes two egg-feeding chains 31 arranged in parallel, two conveyor sprockets 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com