Improved casein products and CO2 reversible acidification methods used for their production.

A casein and casein glue technology, applied in cheese substitutes, peptide/protein components, animal protein processing, etc., can solve the problems of slow rehydration and poor solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Example 1. Standard Preparation of Milk Protein Concentrate

[0094] MPC is prepared from skim milk by a pressure-driven process called ultrafiltration (UF) using a semipermeable membrane. Lactose and minerals are removed by UF until the desired protein content is reached. The membrane retains a concentrated protein fraction in a fraction known as the retentate. Lactose and minerals flow through the membrane into a fraction known as the permeate.

[0095] The retentate is typically spray dried to produce MPC powder. The MPCs prepared in this manner were commercially available with various protein contents including MPC85 from Murray Goulburn Cooperative Co. Ltd. (Melbourne, Australia) and various other suppliers. MPC can be fresh powder, or reconstituted by spray drying.

Embodiment 2

[0096] Example 2 Novel method for preparing milk protein concentrate

[0097] In certain embodiments, the method of the invention comprises acidifying the casein-containing milk or aqueous milk product by applying to the milk under pressure an amount of gas capable of reducing the pH of the milk or aqueous milk product to less than 6.4 in a chamber . The chamber is then degassed, raising the pH of the milk or aqueous milk product to its pre-acidified level and releasing the pressure. The resulting composition comprises casein micelles, at least some of which are altered in structure compared to natural casein micelles.

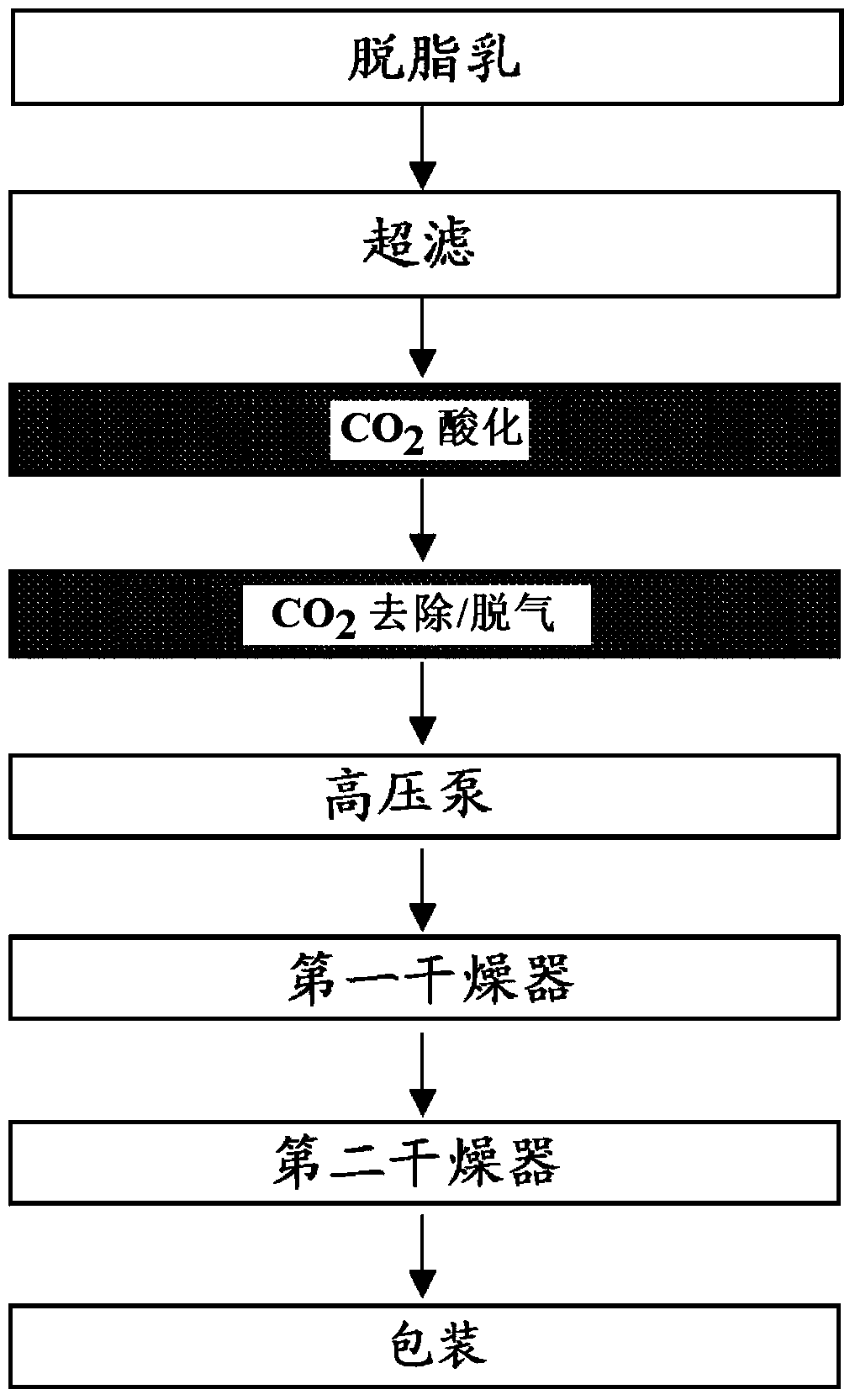

[0098] exist figure 1 The method is schematically shown in , which includes an optional ultrafiltration step in the present invention. In preparing MPCs with altered physicochemical properties according to embodiments of the present invention, carbon dioxide gas is applied to the MPCs in a chamber until the pH drops to 6.4 or lower (preferably 5.2 to 5.8) a...

Embodiment 3

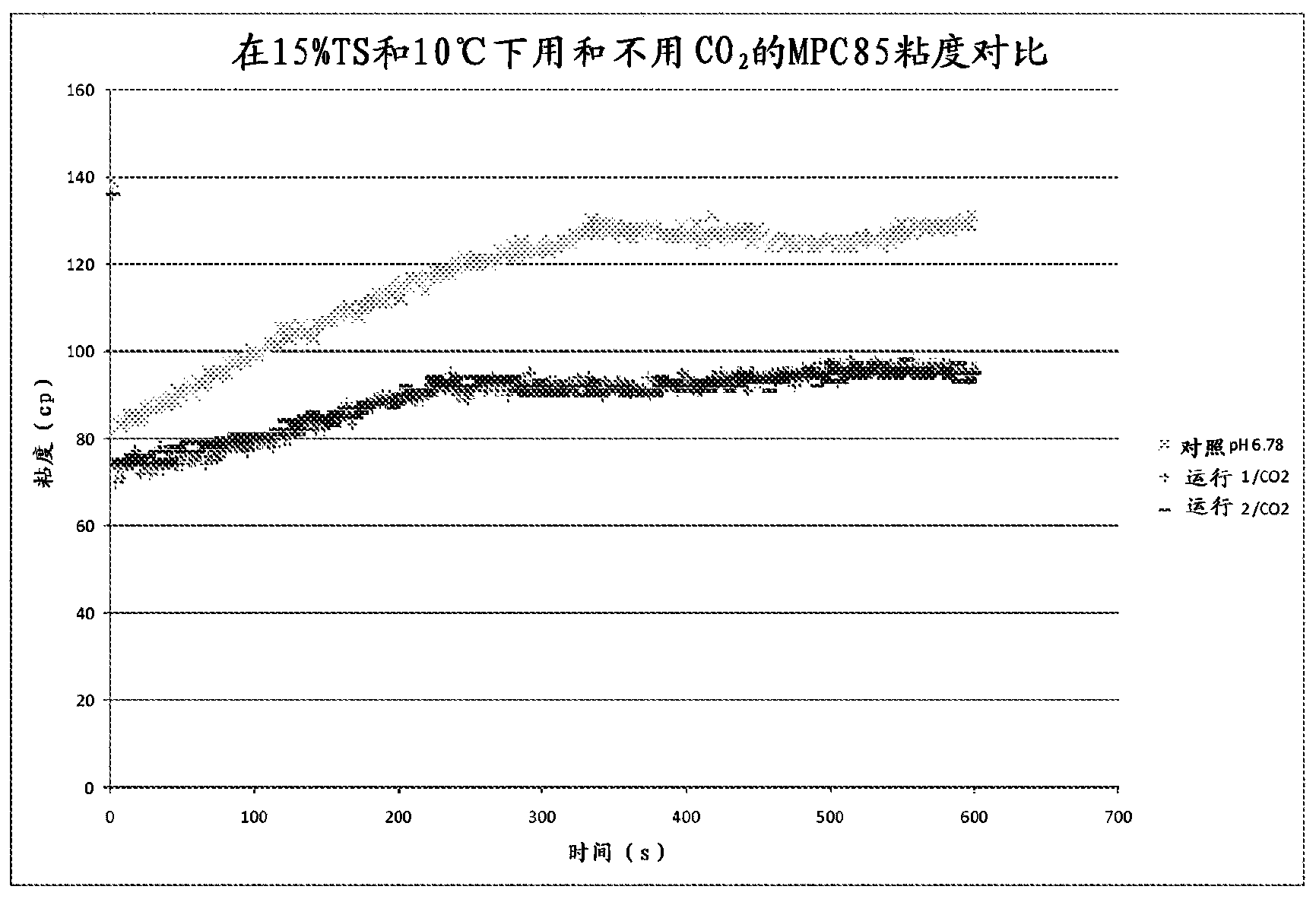

[0102] The viscosity comparison of embodiment 3 commercially available MPC and the MPC prepared by embodiment 2

[0103] Commercially available spray-dried MPC85 powder (control) prepared according to Example 1 and obtained from Murray Goulburn Cooperative Co. Limited (Melbourne, Australia) was mixed with the product prepared by the method of Example 2 (run 1CO 2 and run 2CO 2 ) was reconstituted in water to a total solids concentration of 15% and cooled to 10°C. Its viscosity was measured over a period of 10 minutes using a Newport Scientific RVA 4 Texture analyzer at 10°C and a constant stirring speed of 500 rpm. exist figure 2 The results shown in show that, over time, the viscosity of MPC85 prepared according to the invention (70 cP to 95 cP) was significantly reduced compared to the viscosity of the control (80 cP to 135 cP).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com