Ultrasonic gauge

An ultrasonic and measuring instrument technology, applied in the field of ultrasonic measuring instruments, can solve problems such as incomplete removal, reduced measurement accuracy, and scrapped pipelines, so as to increase product interchangeability, reduce mold costs, and reduce defective products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

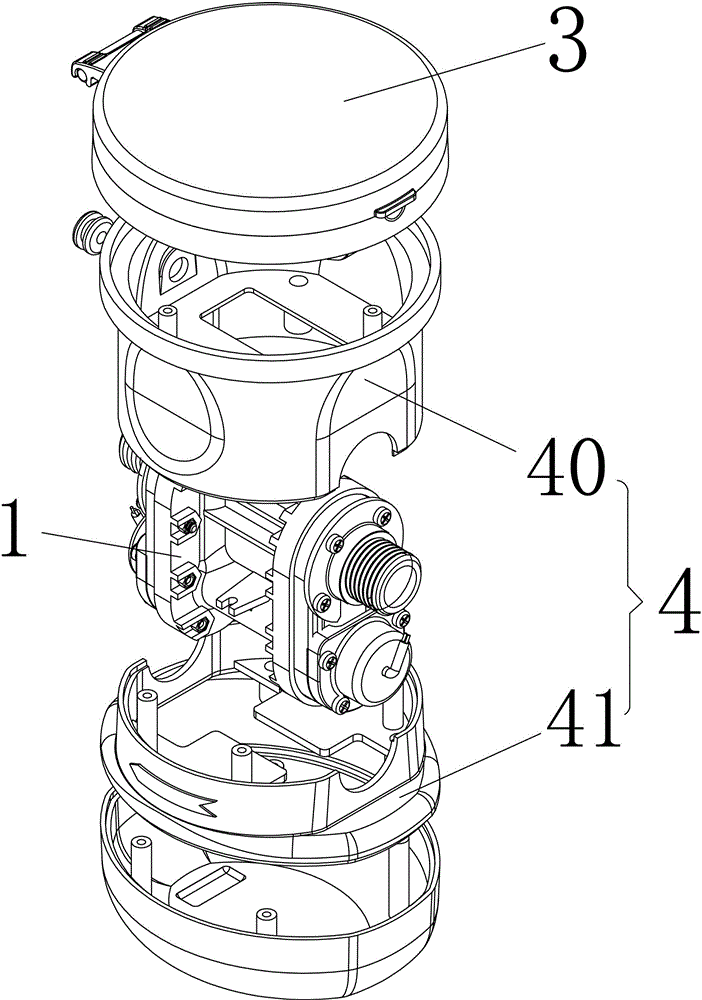

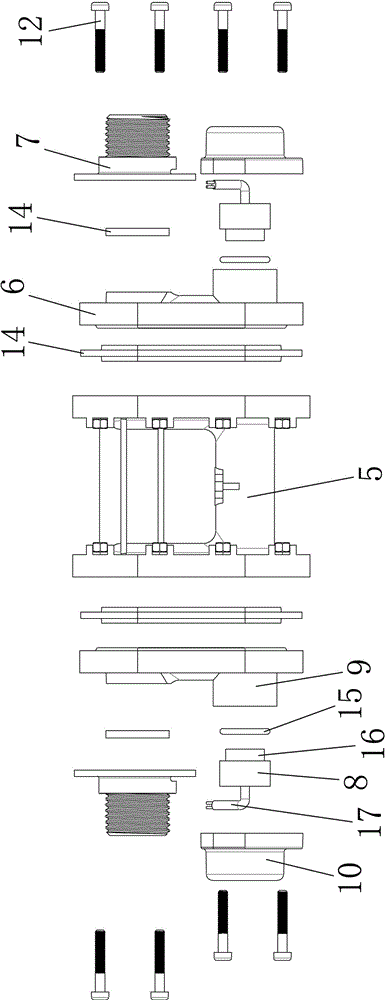

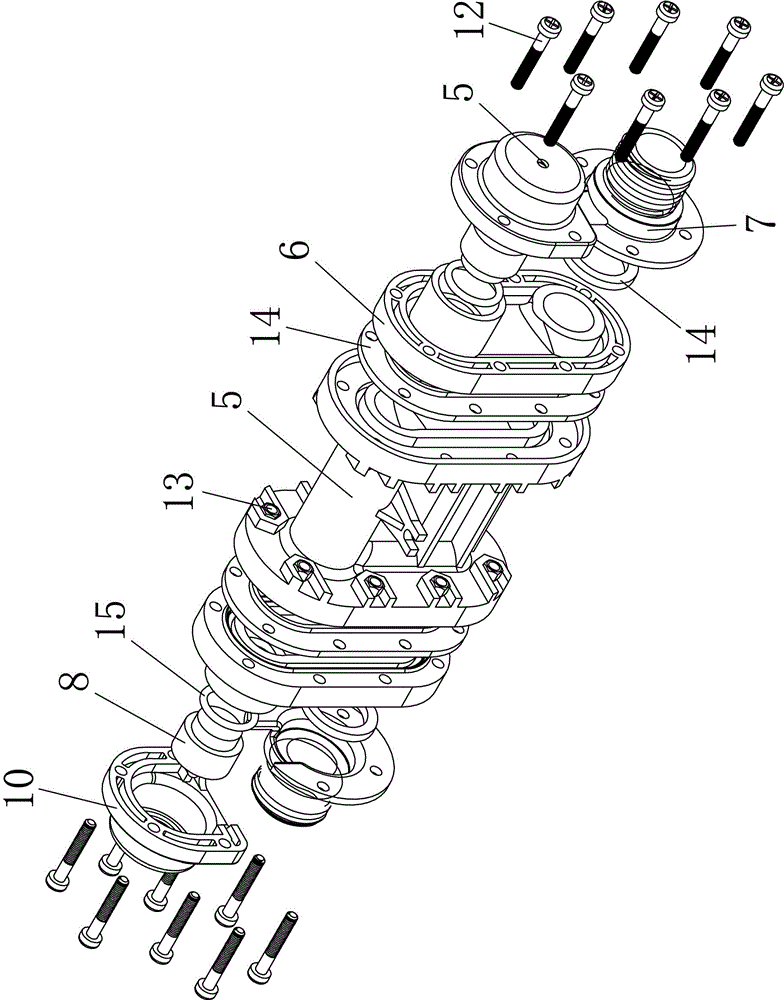

[0031] like figure 1 , 2 , 3, 4, and 5, an ultrasonic meter includes a U-shaped pipe 1 with two ends, an electronic circuit 2, a first housing 3 for accommodating the electronic circuit 2, and accommodating the U-shaped pipe 1 of the second housing 4 and more than two ultrasonic transducers 8, the ultrasonic transducers 8 are connected to the electronic circuit 2 through corresponding wires 17; wherein, the ultrasonic transducers 8 are waterproof , and pass through the inner wall of the U-shaped pipe 1 in the second housing 4 , and directly contact the liquid in the U-shaped pipe 1 . The ultrasonic transducer 8 is directly attached to the inner wall of the U-shaped pipe 1 and is in direct contact with the fluid, and the surrounding edge of the transducer is closely attached to the surrounding edge of the pipe to ensure that the two transducers can be instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com