Automatic online steel rail straightness measuring instrument

A technology of automatic measurement and flatness, applied in measurement devices, instruments, optical devices, etc., can solve the problems of unbalanced pressure, no historical data and curves, easy distortion of measured values, etc., to achieve the effect of uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

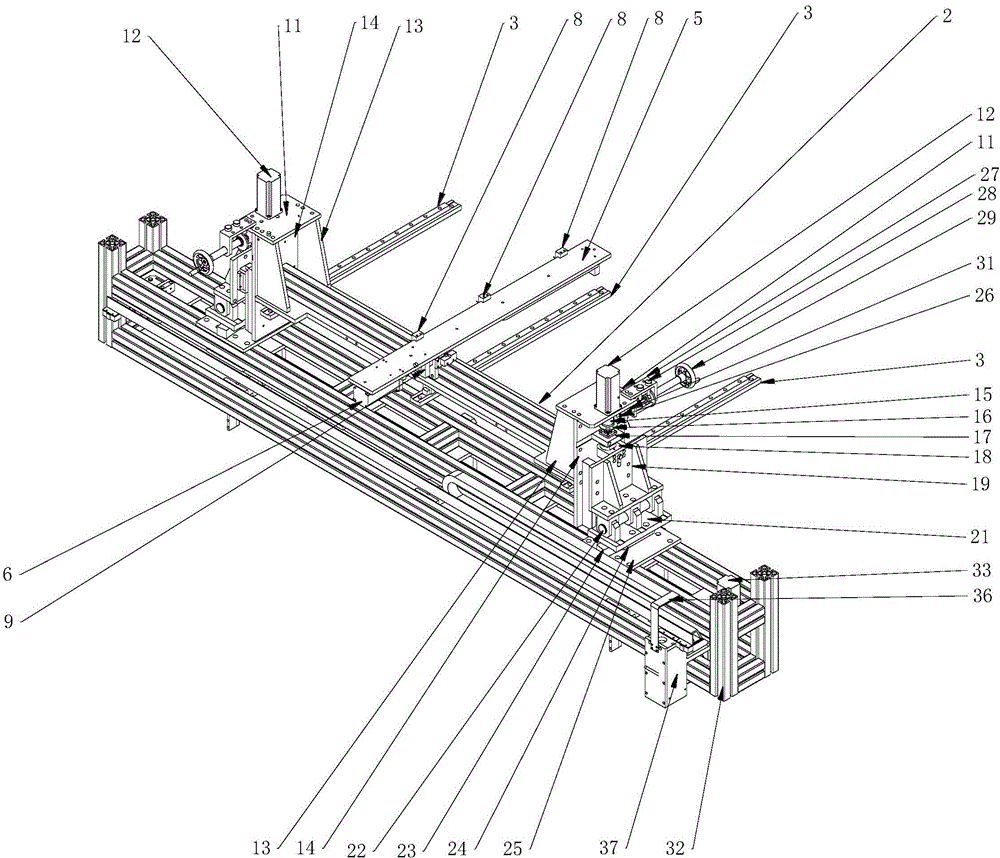

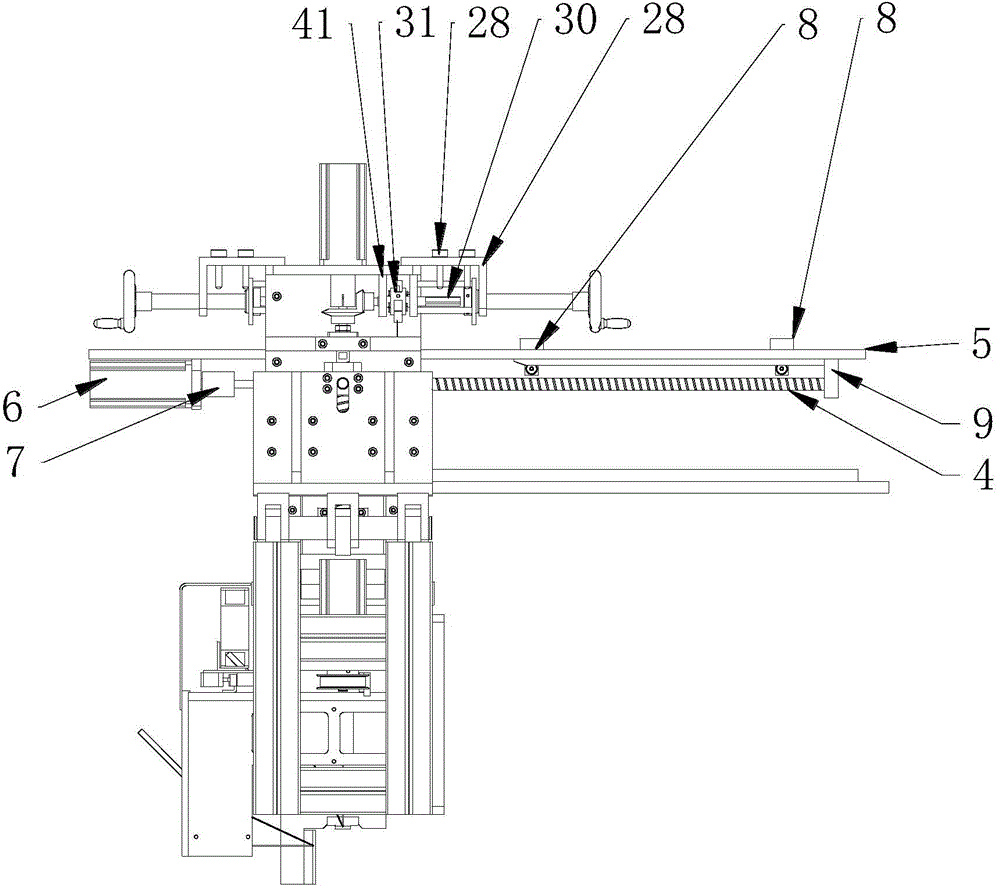

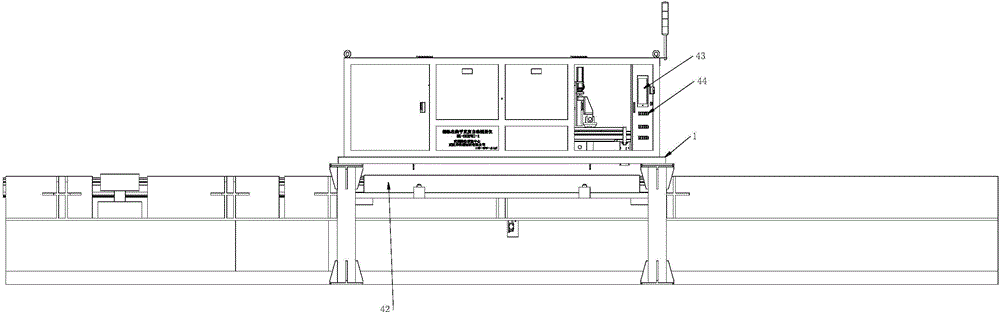

[0027] Example: such as figure 1 A kind of on-line rail straightness automatic measuring instrument shown, comprises frame 1, and described frame 1 is provided with measuring ruler frame 32, and described measuring ruler frame 32 is provided with the measuring trolley 37 that moves longitudinally, so The measuring trolley 37 is provided with a measuring mechanism for measuring the straightness of the rail, and the frame 1 is also provided with a plurality of parallel and transversely arranged translation slide rails 3, and the translation slide rails 3 are provided with longitudinally arranged The translation beam 2, the translation beam 2 is slidingly connected with the translation slide rail 3; the frame 1 is provided with a translation mechanism that enables the translation beam 2 to move laterally on the translation slide rail 3; The two ends of the translating beam 2 are provided with an automatic lifting mechanism that makes the measuring frame 32 move vertically.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com