Adjustable jump detection mechanism

A jump detection and adjustable technology, applied in the direction of measuring devices, instruments, electrical devices, etc., can solve the problems of complex and clumsy detection operations, easily damaged objects to be detected, and low detection accuracy, and achieve light structure, collision prevention, The effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content and structural features of the present invention in detail, the following will further explain in conjunction with the embodiments and the accompanying drawings.

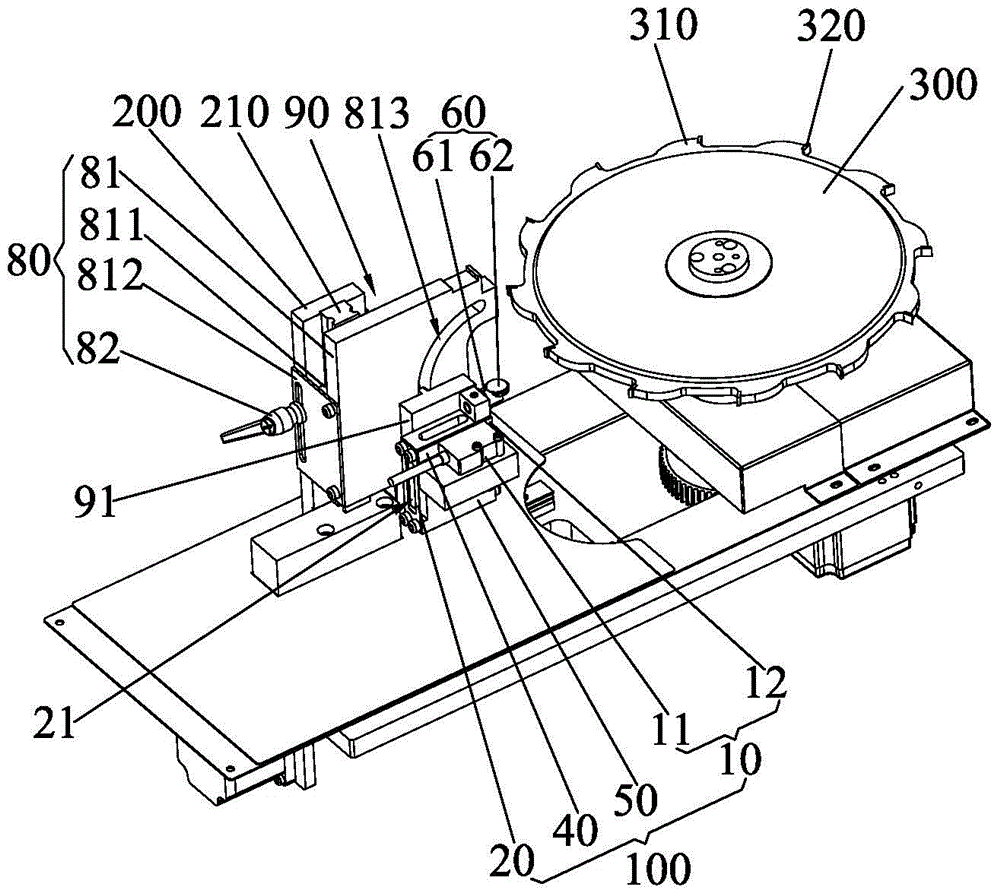

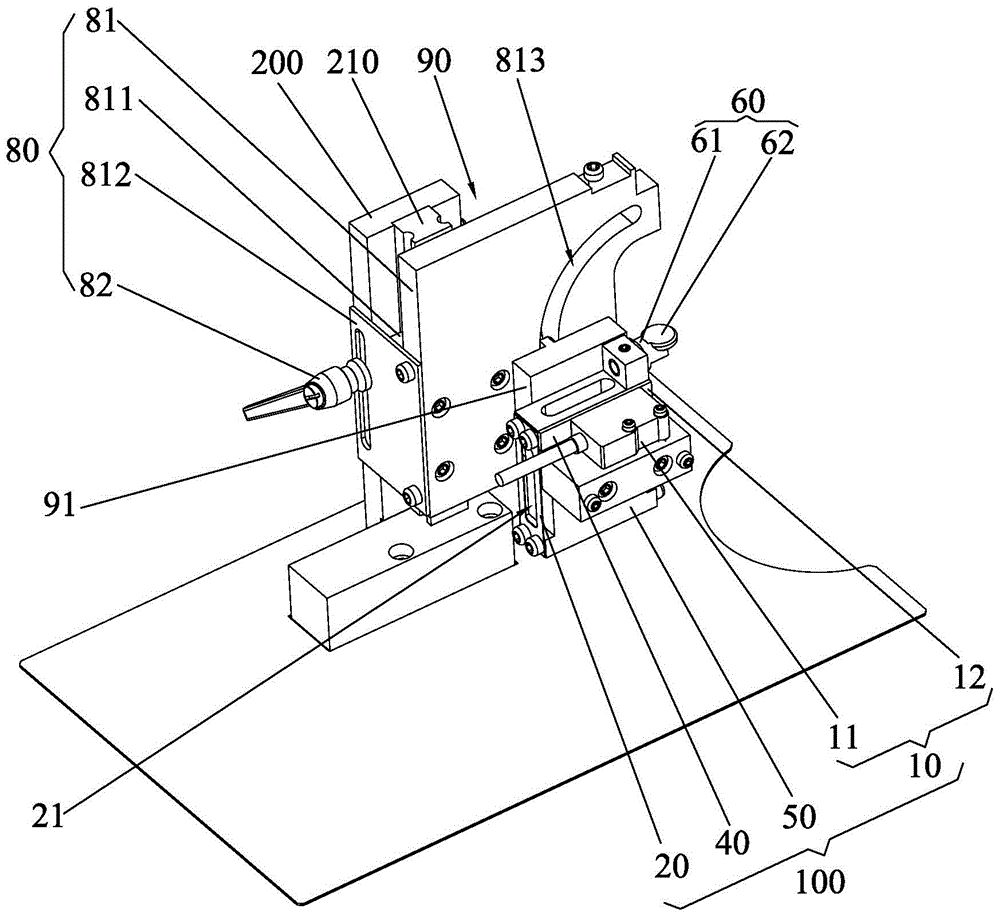

[0027] See figure 1 , The adjustable bounce detection mechanism 100 of the present invention is set on the frame 200, and performs bounce detection on the object to be detected; specifically, as figure 1 As shown, the adjustable runout detection mechanism 100 of the present invention is preferably applied to the radial runout detection of the welding tab 320 of the disc cutter 300 welded to the saw tooth 310. Of course, in other embodiments, the present invention The adjustable runout detection mechanism 100 can also be used to perform axial runout detection of other objects, etc., so the above examples are not limited.

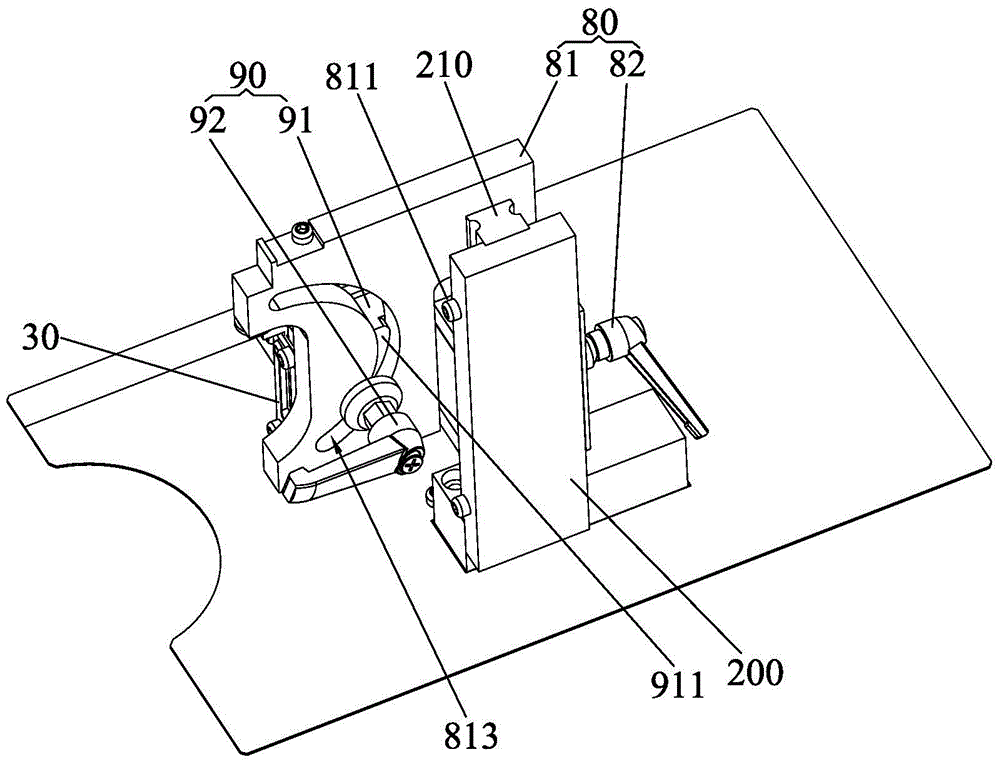

[0028] Please combine Figure 2 to Figure 7 The adjustable runout detection mechanism 100 of the present invention includes a magnetic scale 10, a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com