A kind of composite gas hydrate polymerization inhibitor and its application

A technology of gas hydrate and polymerization inhibitor, which is applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc. It can solve the problems of unsatisfactory anti-polymerization effect, poor biodegradability, high price, etc., and achieves good application prospects , low addition amount, good anti-polymerization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1. Composite gas hydrate inhibitor and its application performance evaluation

[0037] The composite gas hydrate polymerization inhibitor of this example is prepared by mixing dodecyl betaine and polyol type nonionic surfactant Span 20 (HLB value 8.6) at a mass ratio of 1:1.

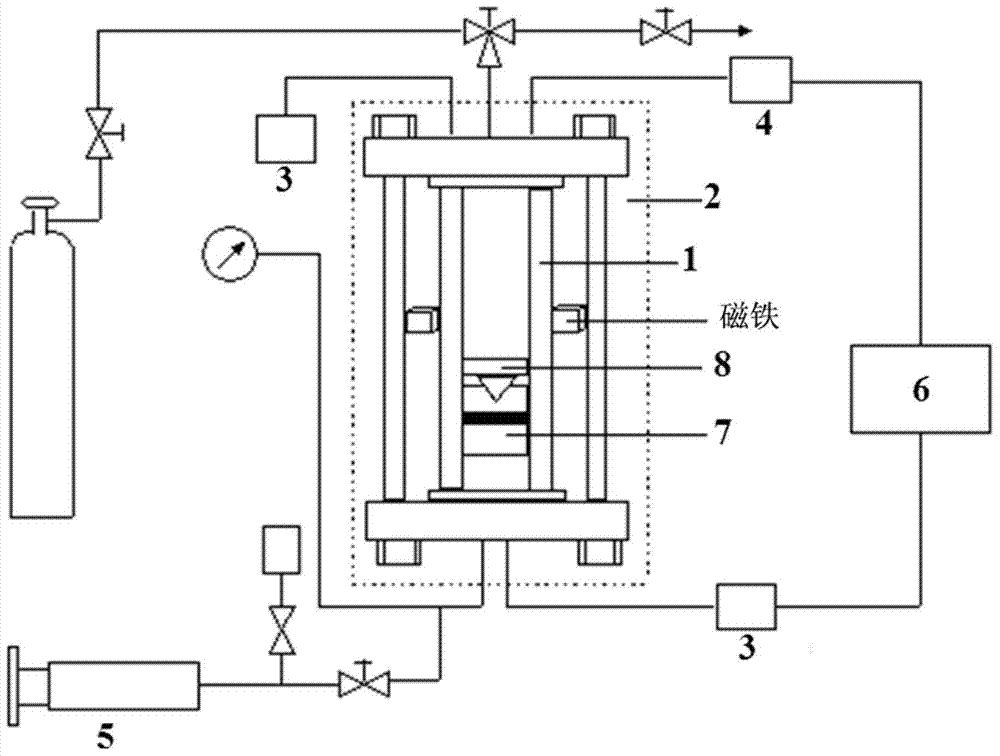

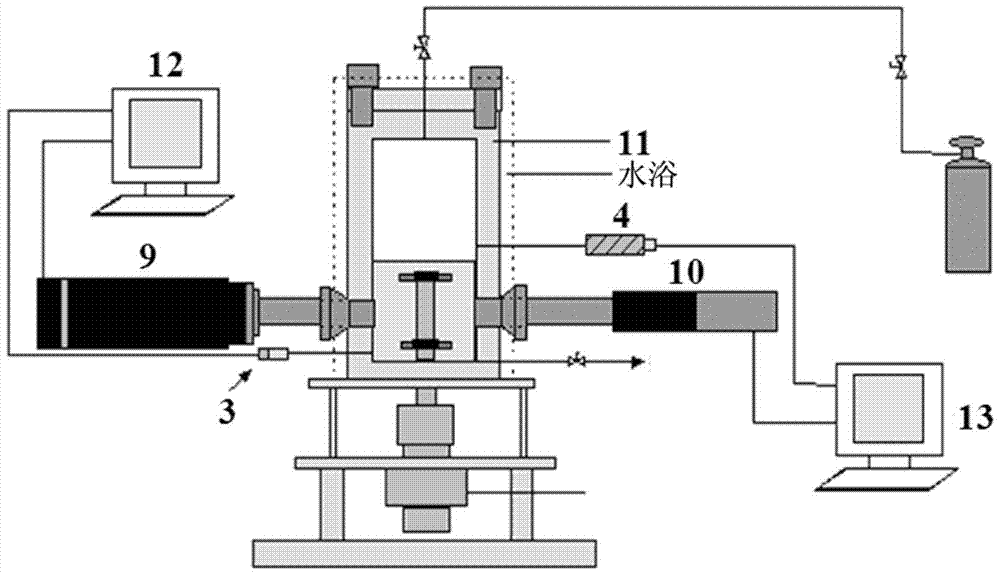

[0038] In this embodiment, a fully transparent sapphire autoclave is used for the application evaluation test. The structure of the fully transparent sapphire autoclave is as follows: figure 1 shown. The reaction kettle is a common equipment for evaluating the inhibitory effect of gas hydrate polymerization inhibitors on gas hydrate aggregation. It mainly includes high-pressure sapphire reaction kettle body 1, constant temperature air bath 2, temperature sensor 3 and pressure sensor 4, hand pump 5, Stirring system and computer data automatic acquisition system6. The maximum working volume of the high pressure sapphire reactor is 49cm 3 (including piston 7 and stirring bar 8), the maximu...

Embodiment 2

[0050] Example 2. Composite gas hydrate inhibitor and its application performance evaluation

[0051] The composite gas hydrate polymerization inhibitor of this example is prepared by mixing lauryl betaine and polyol type nonionic surfactant Span 20 (HLB value 8.6) at a mass ratio of 0.5:1.

[0052] Adopt the application evaluation test of polymerization inhibitor as in embodiment 1, concrete test process is as described in embodiment 1.

[0053] In this example, an oil-water system consisting of 1.5ml of deionized water and 13.5ml of -20# diesel oil was added to the reactor, that is, a mixture with a water content of 10% (based on the sum of the volumes of water and oil) Infusion system; the addition amount of the composite gas hydrate polymerization inhibitor in this embodiment is 3.0% of the water quality in the system, and its use effect is evaluated.

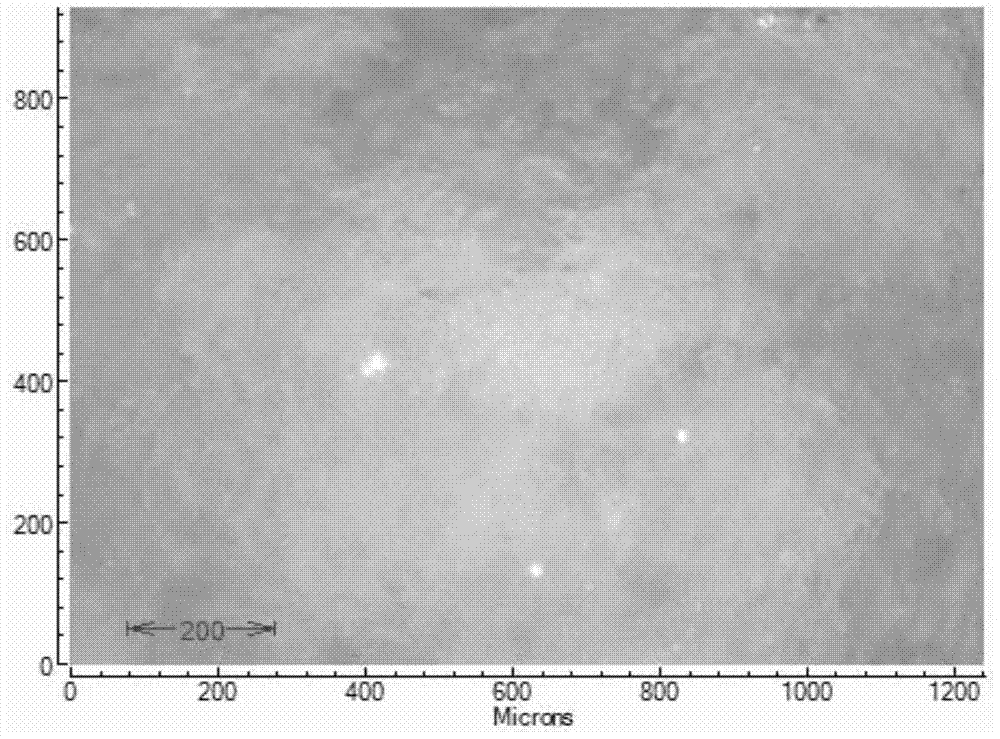

[0054] During the whole experiment process of this example, the gas hydrate particles were uniformly dispersed in the oi...

Embodiment 3

[0055] Example 3. Composite gas hydrate inhibitor and its application performance evaluation

[0056] The composite gas hydrate polymerization inhibitor of the present embodiment is composed of lauryl betaine and polyol type nonionic surfactant Span 20 (HLB value is 8.6) with a mass ratio of 2:1 Mixed to get.

[0057] Adopt the application evaluation test of polymerization inhibitor as in embodiment 1, concrete test process is as described in embodiment 1.

[0058] In this example, an oil-water system consisting of 1.5ml of deionized water and 13.5ml of -20# diesel oil was added to the reactor, that is, a mixture with a water content of 10% (based on the sum of the volumes of water and oil) Infusion system; the addition amount of the composite gas hydrate polymerization inhibitor in this embodiment is 3.0% of the water quality in the system, and its use effect is evaluated.

[0059] During the whole experiment process of this example, the gas hydrate particles were uniformly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com