Small-flow control valve

A small flow, control valve technology, applied in the direction of valve lift, valve device, engine components, etc., can solve the problems of large manpower and material resources, easy to wash, poor adjustment accuracy, etc., to solve the problem of small flow adjustment, prolong service life, improve The effect of control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

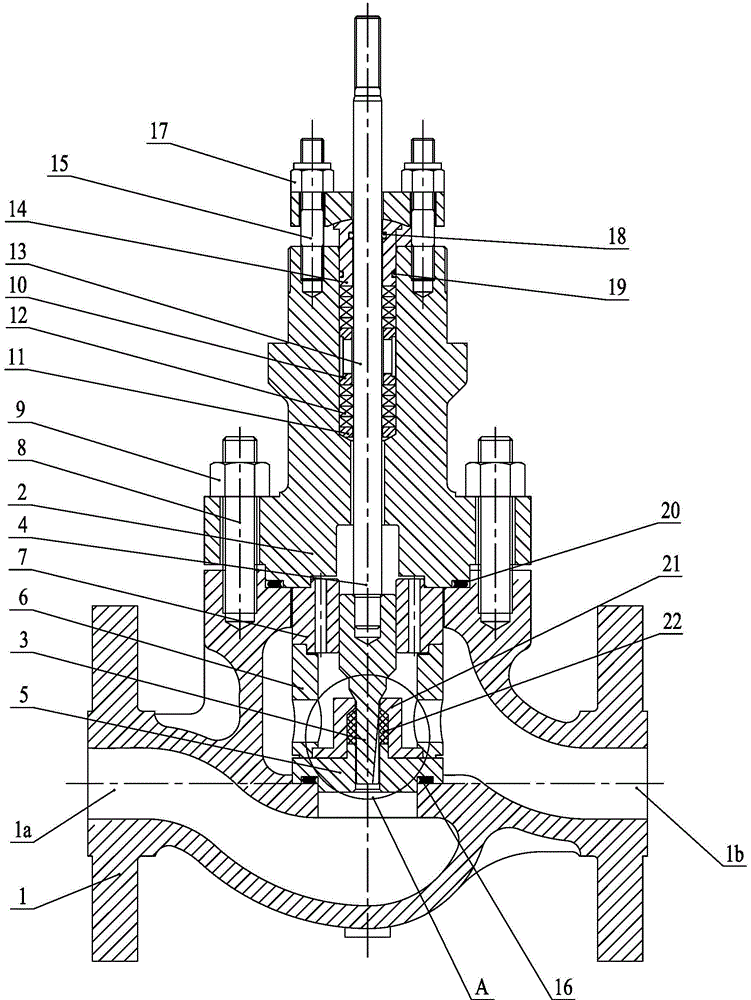

[0019] As shown in the figure: the small flow control valve in the embodiment is mainly composed of a valve body 1, a valve cover 2, a valve core 3, a valve stem 4, a valve seat 5, a spacer 6, a guide sleeve 7, and a first stud 8 , the first hex nut 9, the packing spacer 10, the packing liner 11, the packing 12, the packing gland 13, the packing gland 14, the second stud 15, the valve seat washer 16, the second hex nut 17 , The first O-ring 18, the second O-ring 19, the valve cover gasket 20, the bush seat 21 and the soft sealing bush 22 and so on.

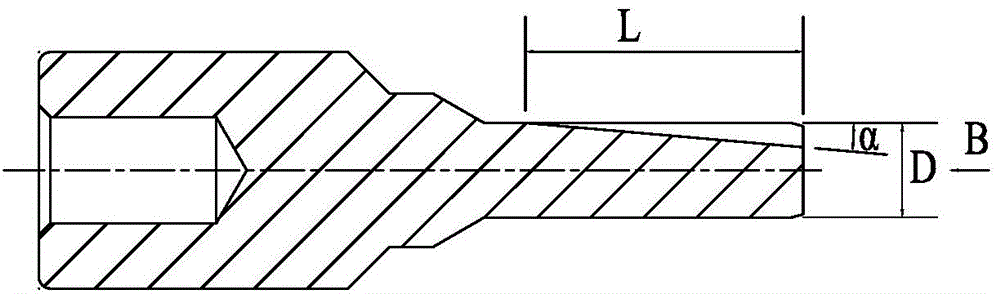

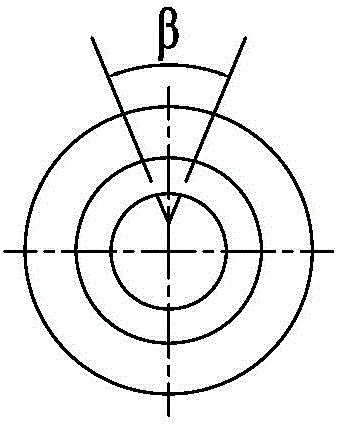

[0020] Such as Figure 1~Figure 4 As shown, the valve body 1 is provided with a valve cavity, the valve seat 5 is installed in the valve cavity, the valve seat 5 is supported by the steps in the valve cavity of the valve body 1, and the contact part between the valve seat 5 and the valve body 1 is in a sealed conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com