Special flange for derrick upright posts and attaching method of special flange

A column and flange technology, which is applied in the field of special flanges for derrick columns and their bonding, can solve problems such as high cost, failure to meet production and construction needs, and large dependence on workers' skill levels, so as to improve bonding rate and welding The effect of high efficiency and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

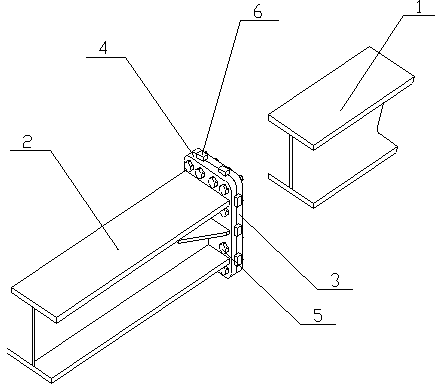

[0017] like figure 1 and figure 2 As shown, the present invention discloses a special flange for a derrick column. The flange is connected between the upper column 1 and the lower column 2, and includes an upper flange plate 3 welded to the bottom of the upper column 1 and welded to the top of the lower column 2. The lower flange plate, the upper flange plate 3 and the lower flange plate are connected back to back, and the flange surfaces of the upper flange plate 3 and the lower flange plate 4 are fixedly connected by bolts 5; the upper flange plate 3 and the lower flange plate 4 are welded and fixed around the joint by the horse plate 6 .

[0018] The present invention also discloses a bonding method for realizing the bonding between the special flanges of the above-mentioned derrick column. The method is first to use a boring and milling machine to process the front and back sides of the upper flange plate 3 and the lower flange plate 4 to ensure smooth surfaces Then the...

Embodiment 2

[0022] In this embodiment, on the basis of Embodiment 1, spot welding is used to fix the joints of the upper flange plate 3 and the lower flange plate 4 with 6 spot welds. When welding, a symmetrical welding process is adopted. Weld from both sides at the same time. When welding, weld the joints around the joints between the horse plate and the upper and lower flange plates. Weld 3-4 times, then clean the root on the back and polish the surface of the base metal for 2- 3mm, take out the carburized layer.

[0023] In this embodiment, through the symmetrical welding process, the welding deformation can be effectively controlled, the bonding rate between the flange plates can be ensured, and the welding efficiency can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com