Chia seed polypeptide and preparation method thereof

The technology of chia seeds and enzymolysis is applied in the field of preparation of chia seed polypeptides, which can solve the problems of hindering the introduction and sales of chia seeds, insufficient depth of development and utilization, high price of chia seeds, etc. The effect of promoting introduction and application, easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of chia seed polypeptide, the method comprising the steps of:

[0032] a. Raw material processing: remove the impurities in the chia seeds, and use a pulverizer to crush the chia seeds.

[0033] b. Raw material dissolution: Fully stir and dissolve the pulverized chia seeds and water at a ratio of 1:20. After the dissolution is complete (30 minutes), stir and raise the temperature to control the temperature of the feed liquid to 50°C.

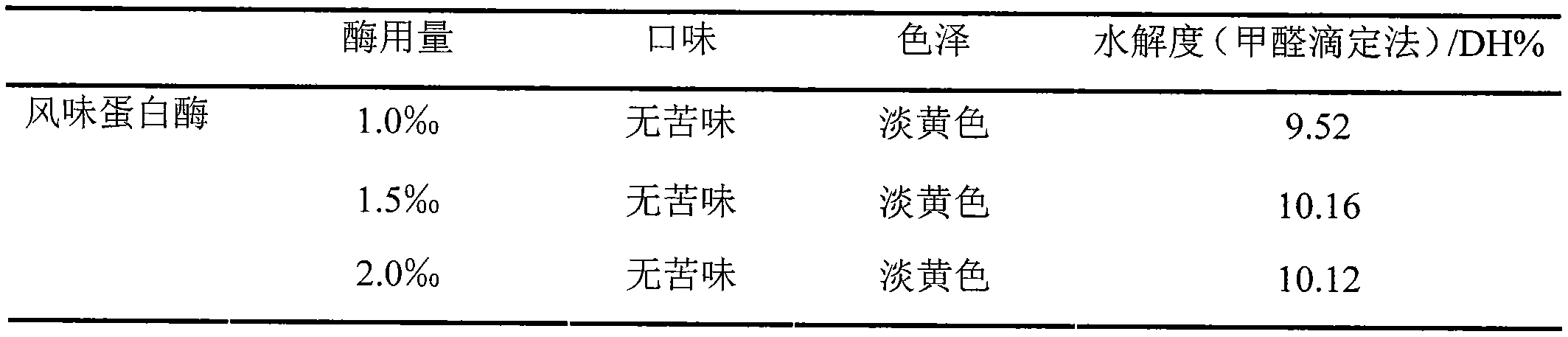

[0034] c. Enzymolysis: under the condition of natural pH value and 50°C, add 0.5‰ of Protamex enzyme and 1.0‰ of flavor protease equivalent to the weight of the substrate to the feed solution with a substrate concentration of 5%, and stir for 4 hours to obtain Chia Seed Enzyme Hydrolyzate.

[0035] d. Enzyme inactivation: Heat the enzymatic solution to 80°C for 20 minutes at a constant temperature to achieve the effect of inactivating the enzyme.

[0036] e. Concentration: Use a double-effect concentrator to concent...

Embodiment 2

[0041] A preparation method of chia seed polypeptide, the method comprising the steps of:

[0042] a. Raw material processing: remove the impurities in the chia seeds, and use a pulverizer to crush the chia seeds.

[0043] b. Dissolution of raw materials: Fully stir and dissolve the pulverized chia seeds and water at a ratio of 1:25. After the dissolution is complete (35 minutes), stir and raise the temperature to control the temperature of the feed liquid to 50°C.

[0044] c. Enzymolysis: under the condition of natural pH value and 50°C, add 1.0‰ of Protamex enzyme and 1.5‰ of flavor protease equivalent to the weight of the substrate to the feed solution with a substrate concentration of 4%, and stir for 4 hours to obtain Chia Seed Enzyme Hydrolyzate.

[0045] d. Enzyme inactivation: Heat the enzymatic solution to 80°C for 20 minutes at a constant temperature to achieve the effect of inactivating the enzyme.

[0046] e. Concentration: Use a double-effect concentrator to conce...

Embodiment 3

[0051] A preparation method of chia seed polypeptide, the method comprising the steps of:

[0052] a. Raw material processing: remove the impurities in the chia seeds, and use a pulverizer to crush the chia seeds.

[0053] b. Dissolution of raw materials: Fully stir and dissolve the pulverized chia seeds and water at a ratio of 1:25. After the dissolution is complete (40 minutes), stir and raise the temperature to control the temperature of the feed liquid to 50°C.

[0054] c. Enzymolysis: under the condition of natural pH value and 50°C, add Protamex enzyme 1.5‰ and flavor protease 2.0‰ equivalent to the weight of the substrate to the feed solution with a substrate concentration of 5%, and stir for 4 hours to obtain Chia Seed Enzyme Hydrolyzate.

[0055] d. Enzyme inactivation: Heat the enzymatic solution to 80°C for 20 minutes at a constant temperature to achieve the effect of inactivating the enzyme.

[0056] e. Concentration: Use a double-effect concentrator to concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com