Method for preparing glycyrrhizic acid derivatives by carrying out subcritical hydrolysis reaction

A hydrolysis reaction, glycyrrhizic acid technology, applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives and other directions, can solve the problems of complex preparation process, long cycle and high cost, and achieve high product yield, low cost, and high production efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

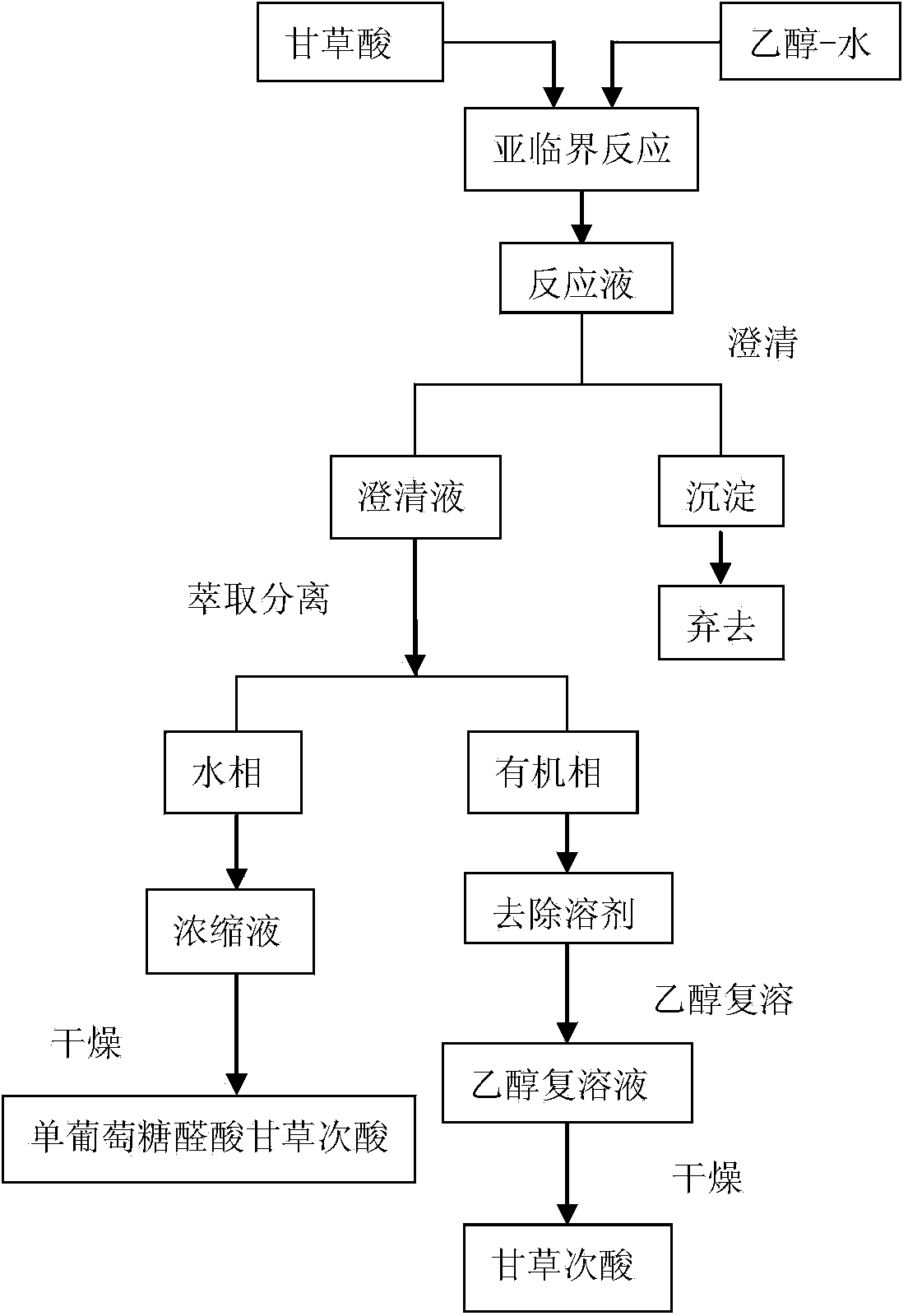

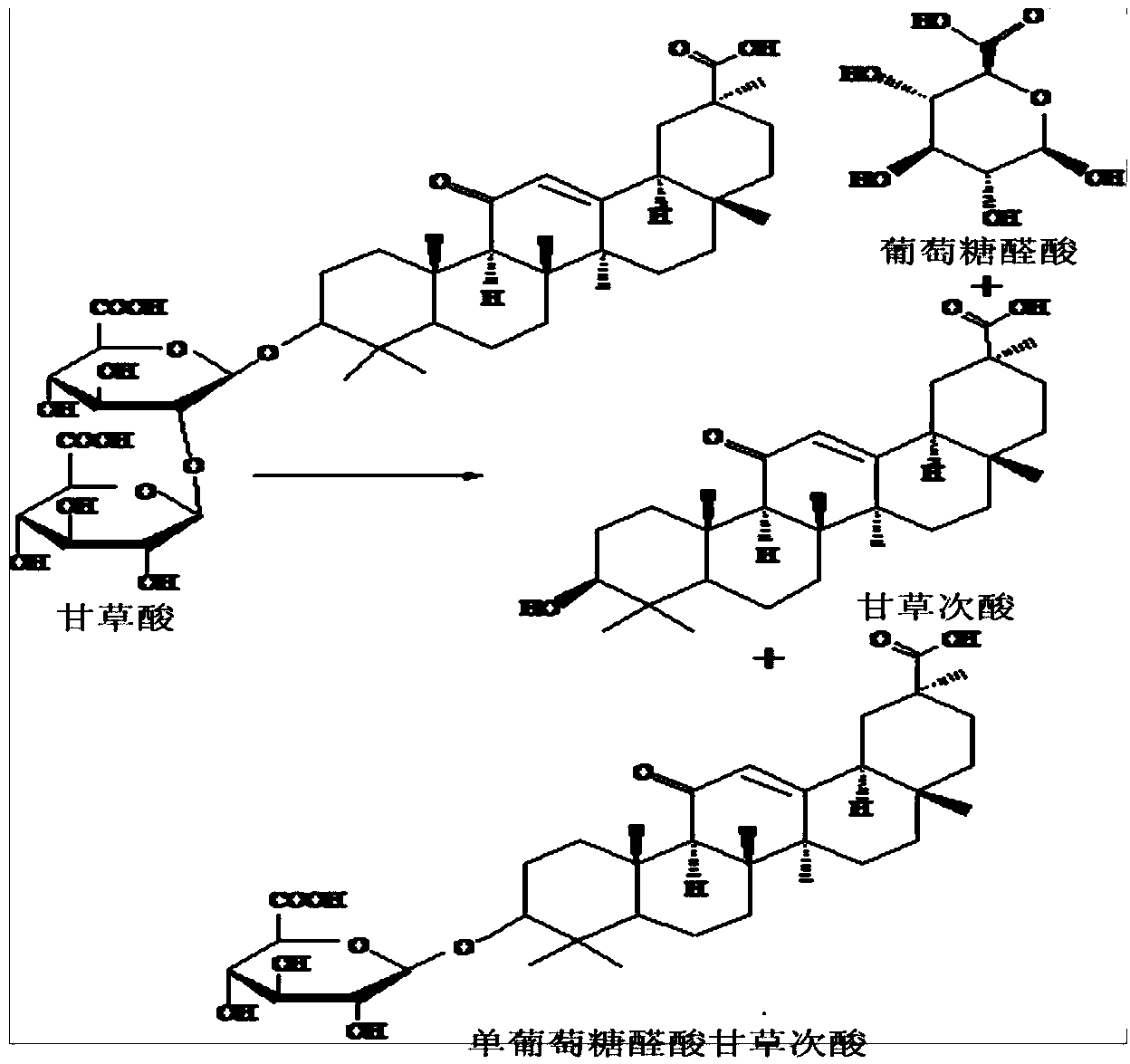

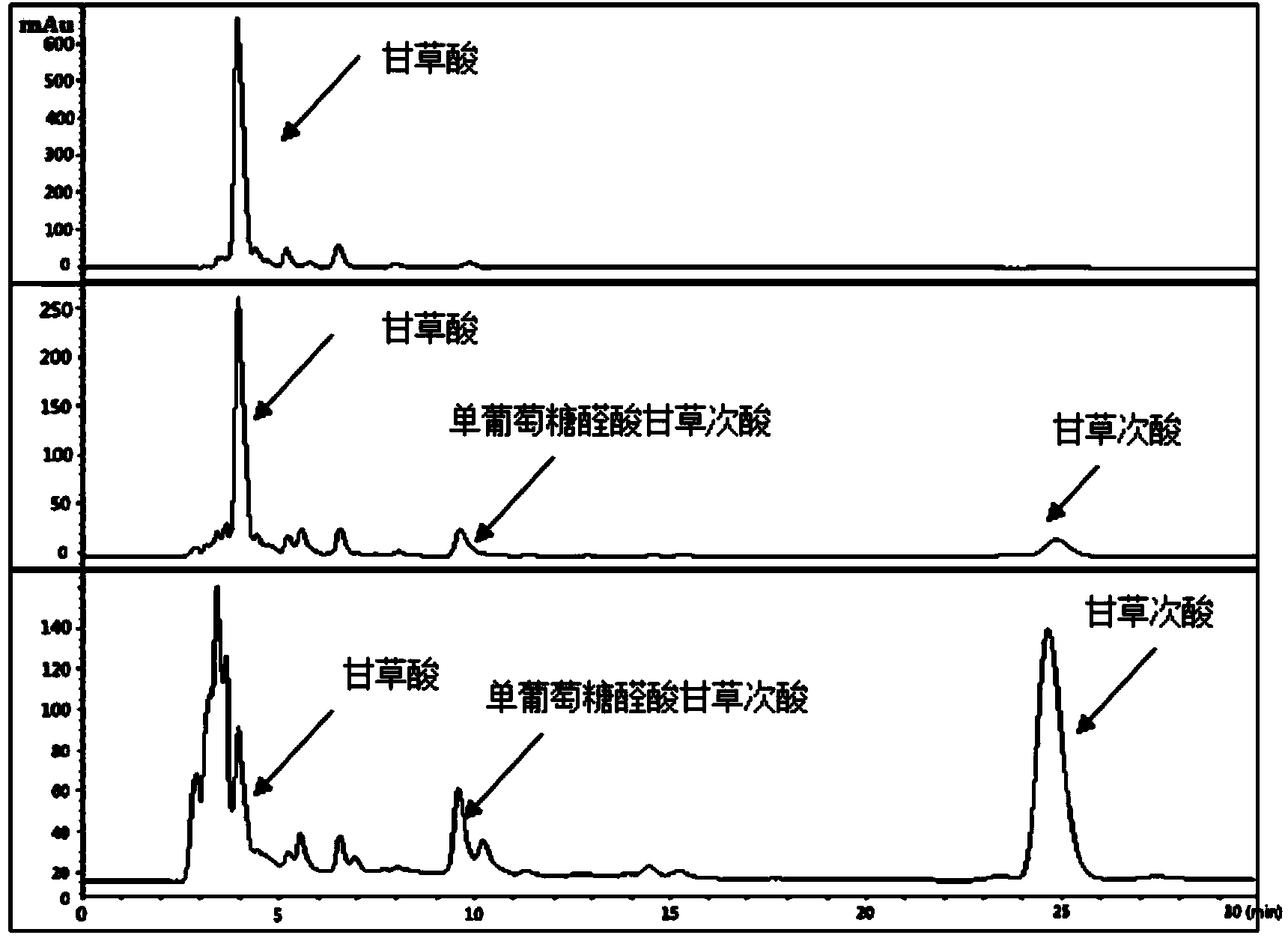

[0028] according to figure 1 The process flow diagram of the preparation of glycyrrhizic acid derivatives by the subcritical hydrolysis reaction shown, prepares monoglucuronic acid glycyrrhetinic acid and glycyrrhetinic acid through subcritical hydrolysis reaction from glycyrrhizic acid, comprising the following steps:

[0029] (1) Raw material dissolution: Dissolve glycyrrhizic acid in 30% ethanol-water solution at 65°C, then add acetic acid to adjust pH=3 to obtain a glycyrrhizic acid solution with a concentration of 1.8%;

[0030] (2) Subcritical hydrolysis reaction: pump the glycyrrhizic acid solution into the subcritical reaction kettle through a high-pressure infusion pump, and carry out stirring reaction under high temperature and high pressure. The reaction temperature is 120°C, the pressure is 5MPa, the time is 50min, and the stirring speed is 100rpm , after the reaction finishes, collect the reaction solution;

[0031] (3) Centrifugal treatment: the above reaction s...

Embodiment 2

[0039] This embodiment discloses a method for preparing glycyrrhetinic acid monoglucuronate and glycyrrhetinic acid from glycyrrhizic acid through subcritical hydrolysis reaction, comprising the following steps:

[0040] (1) Raw material dissolution: Dissolve glycyrrhizic acid in 70% ethanol-water solution at 65°C, then add acetic acid to adjust pH=2 to obtain a glycyrrhizic acid solution with a concentration of 1.8%;

[0041] (2) Subcritical hydrolysis reaction: pump the glycyrrhizic acid solution into the subcritical reaction kettle through a high-pressure infusion pump, and carry out stirring reaction under high temperature and high pressure. The reaction temperature is 160°C, the pressure is 9MPa, the time is 20min, and the stirring speed is 200rpm , after the reaction finishes, collect the reaction solution;

[0042] (3) Centrifugal treatment: the above reaction solution was centrifuged to obtain a clarified liquid, the centrifugal speed was 4200rpm, and the time was 10mi...

Embodiment 3

[0049] This embodiment discloses a method for preparing glycyrrhetinic acid monoglucuronate and glycyrrhetinic acid from glycyrrhizic acid through subcritical hydrolysis reaction, comprising the following steps:

[0050] (1) Raw material dissolution: Dissolve glycyrrhizic acid in 30% ethanol-water solution at 65°C, then add acetic acid to adjust pH=2 to obtain a glycyrrhizic acid solution with a concentration of 3.6%;

[0051] (2) Subcritical hydrolysis reaction: pump the glycyrrhizic acid solution into the subcritical reaction kettle through a high-pressure infusion pump, and carry out stirring reaction under high temperature and high pressure. The reaction temperature is 140°C, the pressure is 7MPa, the time is 70min, and the stirring speed is 150rpm , after the reaction finishes, collect the reaction solution;

[0052] (3) Centrifugal treatment: the above reaction solution was centrifuged to obtain a clarified liquid, the centrifugal speed was 4200rpm, and the time was 10mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com