Aeration pipe with pipe end being hemispheric aeration plate

An aeration tube and hemispherical technology, applied in the field of aeration tubes, can solve the problems of inability to achieve 360° all-round aeration, uneven spatial distribution of dissolved oxygen in water, and weak bubble diffusion effect, etc., to achieve aeration Large range, expanding the scope of aeration, eliminating the effect of aeration dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

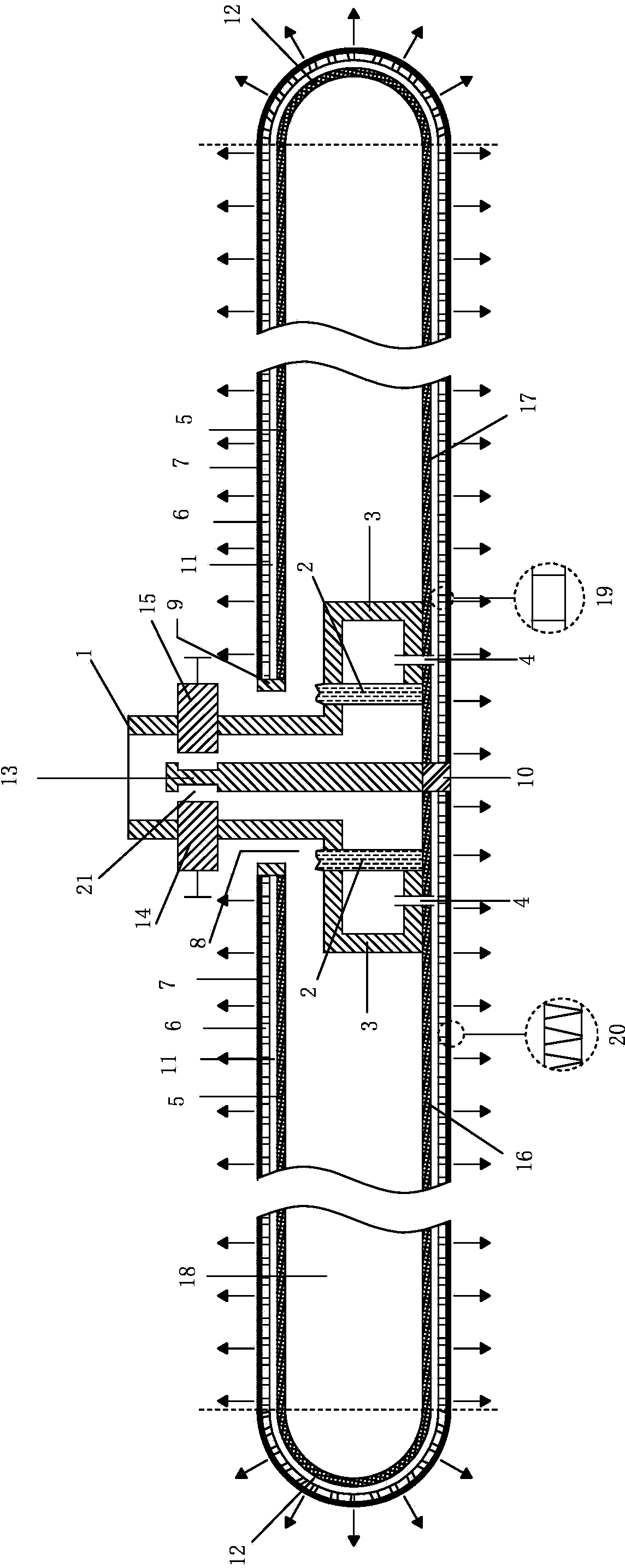

[0024] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

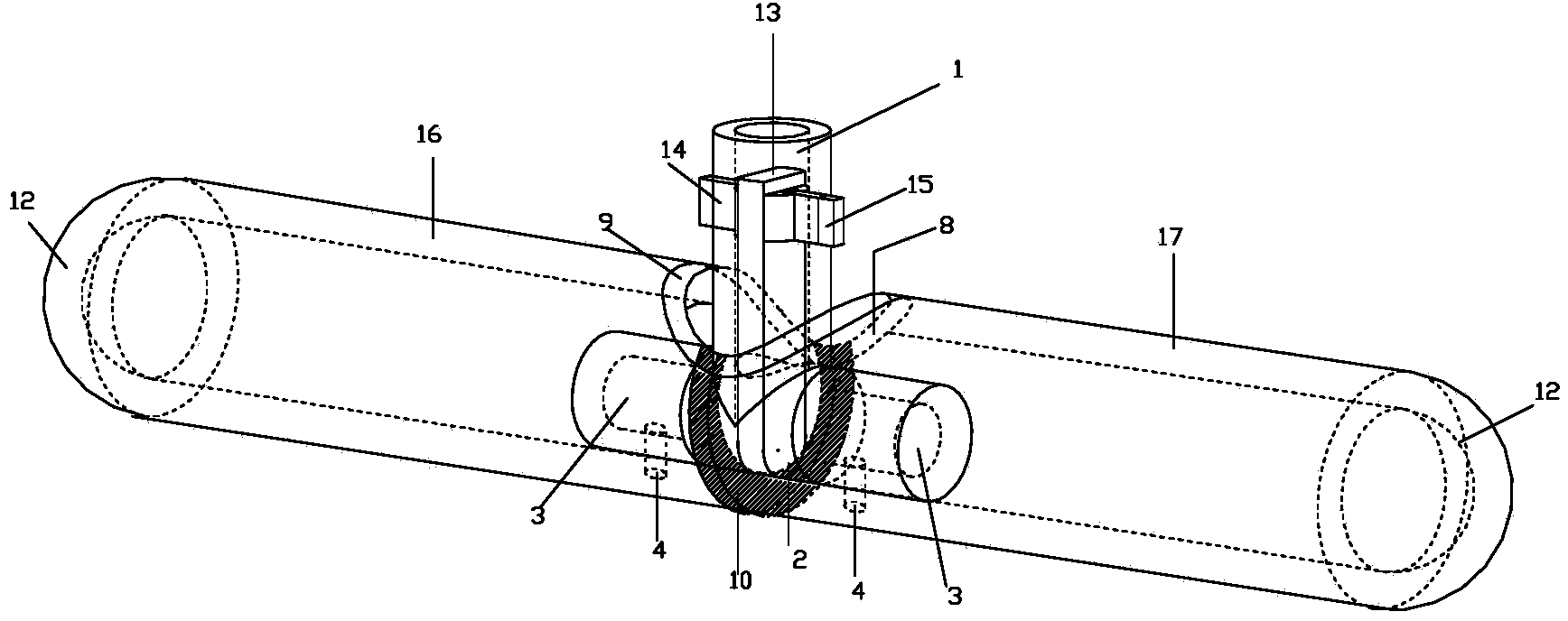

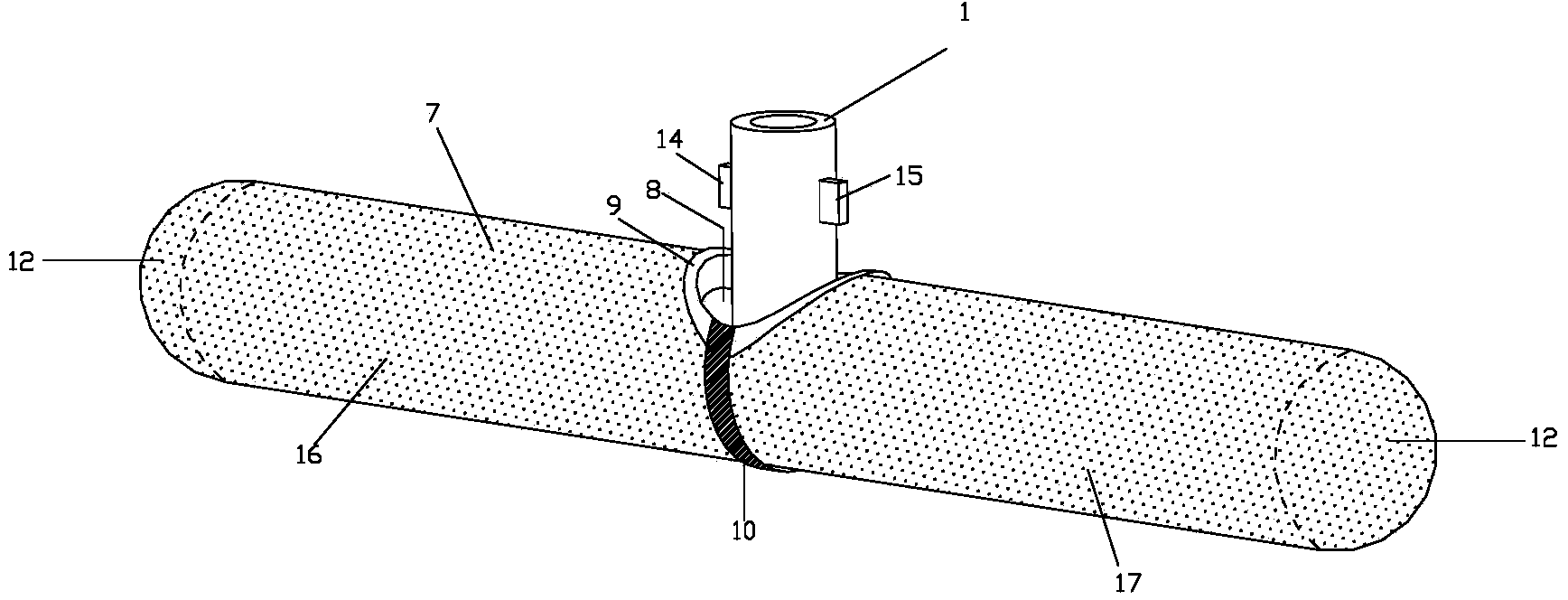

[0025] reference Figure 1-5 , The aeration pipe with a hemispherical aeration plate at the end of the present invention includes an air inlet connecting pipe 1, an air inlet sleeve 2, an air guiding chamber 3, an air guiding hole 4, an inner pipe 5, an outer pipe 6, and a rubber aeration pipe membrane 7. Water inlet channel 8, restraint ring 9, partition 10, hemispherical pipe end 12, air partition 13 and left and right control valves 14 and 15.

[0026] The outer tube 6 and the inner tube 5 are arranged in concentric circles and can be made of stainless steel, ABS or UPVC. The diameter of the inner tube 5 is slightly smaller than the outer tube 6, and an equidistant airway 11 is formed between the outer tube 6 and the inner tube 5 , The outer tube 6 is evenly distributed with a plurality of equal diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com