A differential flap rudder control cabin structure

A technology for controlling cabins and cabins, which is applied to aircraft transmissions, aircraft power transmission, aircraft power devices, etc., can solve the problems of unseen technical reports, late start, and the control mode is not a differential control mode, and can solve the problem of installation. bad operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

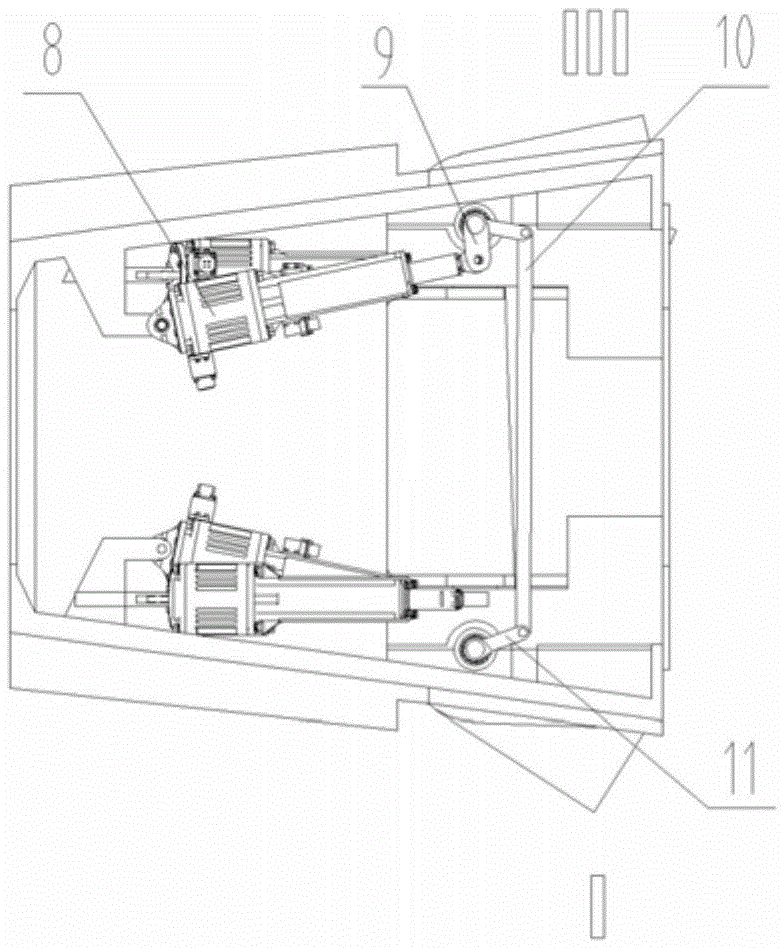

[0018] like figure 1 As shown, the yaw channel II and IV quadrants of the present invention each have a FLAP rudder, and the II rudder 6 and the IV rudder 7 are each driven by an actuator 8; the I quadrant has an I 1 Helm 3 and I 2 Rudder 5, III quadrant has III 1 Helm 2 and III 2 Rudder 4, where I 1 Helm 3 and III 1 Rudder 2 rotates synchronously, driven by an actuator 8, I 2 Helm 5 and III 2 The rudders 4 rotate synchronously, driven by an actuator 8, and the two groups of rudders rotate independently of each other to realize the differential control of the pitch channel.

[0019] like figure 2 As shown, an actuator 8 is hinged with the rocker arm I9, the rocker arm I9 is connected with the rotating shaft I19 as a whole, and the rotating shaft I19 and III 1 The rudder 2 is connected by a key, one end of the connecting rod 10 is hinged to the other fulcrum of the rocker arm I9, the other end of the connecting rod 10 is hinged to the rocker arm II11, and the rocker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com