Pasture and biomass briquetting machine

A briquetting machine and biomass technology, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as no consideration, and achieve the effects of reducing replacement costs, high efficiency, and safe and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

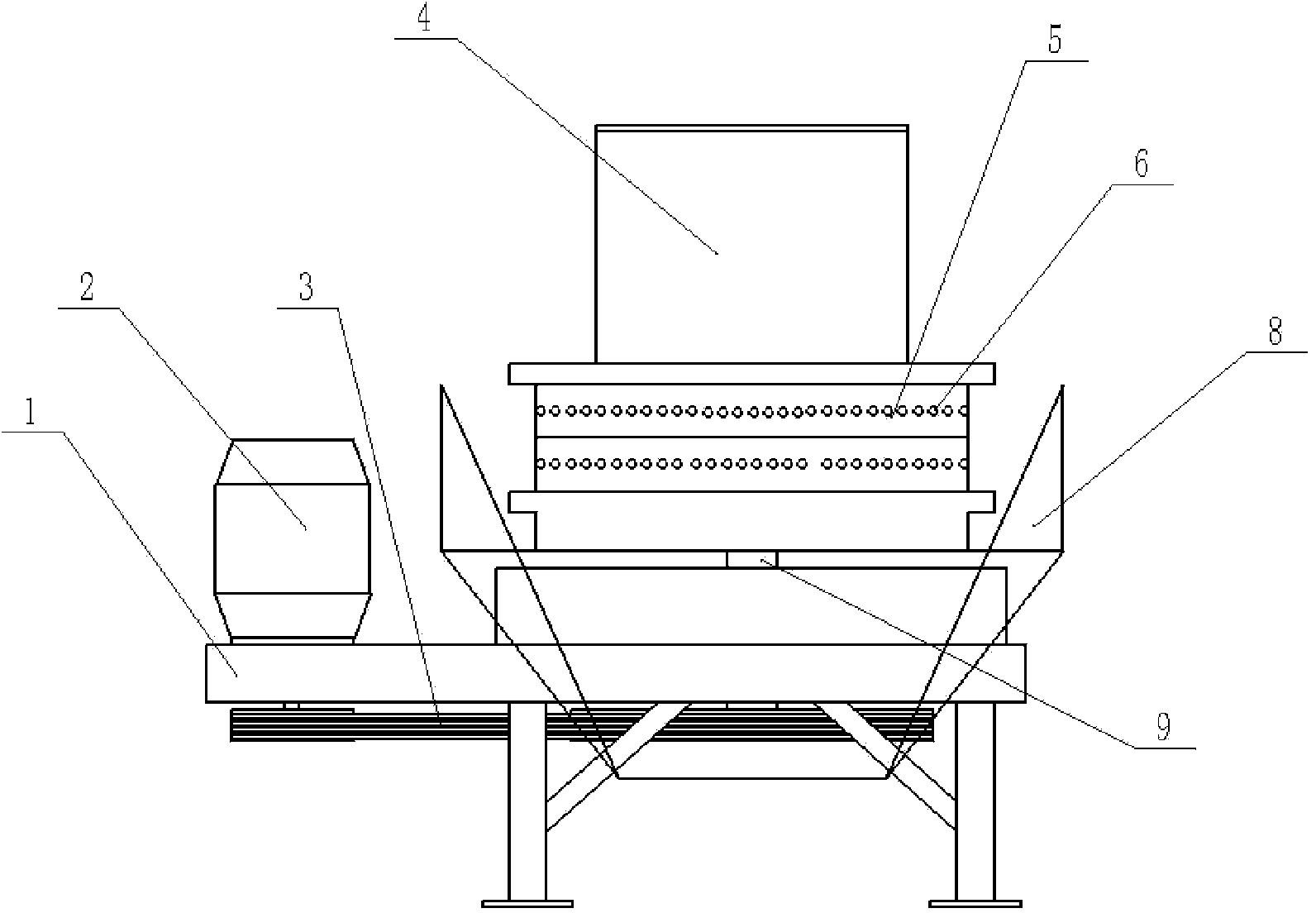

[0030] Such as figure 1 As shown, the pasture and biomass briquetting machine of the present invention include a frame 1, a motor 2, a transmission belt 3, a hopper 4, a mold plate 5, a collection discharger 8, a main shaft 9 and a plurality of die sets 7 .

[0031] Such as image 3 As shown, the mold plate 5 is a hollow disc, and its side wall is provided with a mold hole 6 that is horn-shaped toward the center of the mold plate 5, and the mold cover 7 is inserted into the mold hole 6 and is matched with the mold plate 5 clearances; The cover 7 is a horn-shaped cylindrical or cuboid cylinder facing the center of the mold plate 5. Different mold covers 7 have different lengths and / or inner diameters, such as Figure 2a~2c As shown, wherein, the length of the die sleeve 7 of the second embodiment is dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com