Composite counter-weight block grinding ultra-flat production line

A technology for counterweights and production lines, applied in grinding/polishing equipment, grinding/polishing safety devices, grinders, etc., can solve problems such as occupational health and safety injuries of employees, inability to guarantee production quality, and serious pollution on the job site. The effect of reducing labor intensity of workers, controlling product flatness and dimensional accuracy requirements, and reasonable overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects provided by the present invention will be described in detail as follows:

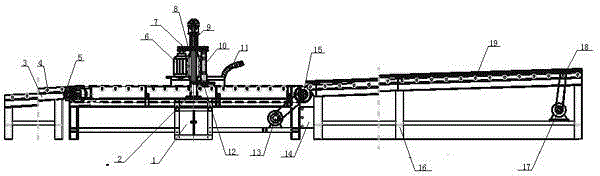

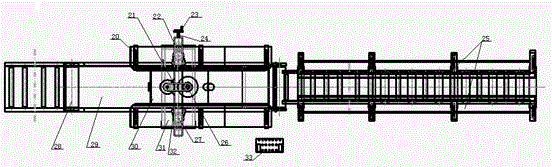

[0012] Such as figure 1 and figure 2 As shown, a compound counterweight grinding ultra-flat production line, including the upper part, the lower part, the host part, the main machine feeding and feeding part and the electric control console, can be adjusted arbitrarily according to the width of the compound counterweight during work. The workpiece automatically enters the grinding surface of the main machine through the upper active roller table 16, and is discharged from the lower active roller table 3, with a total length of 10.35 meters. The host part is composed of host body 1 and guide column 2, dust collector suction port 11, connecting plate 14, adjustment screw 20, dust cover 30, positioning mobile baffle 31, drive shaft motor 6, pulley 7, power b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com