A continuous stamping die for manufacturing antenna terminals of wearable belt devices

An antenna terminal, stamping die technology, applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of high production cost, reduced enterprise efficiency, waste of human resources, etc., to reduce usage, improve production efficiency, reduce The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

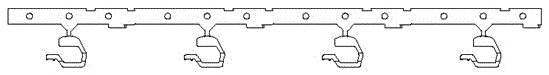

[0021] Design a continuous progressive mold that includes all processing steps for the manufacture of antenna terminals for wearable belt devices, and a set of molds can achieve high-precision terminal production.

[0022] The main template of the mold includes an upper mold and a lower mold. The upper mold includes: upper mold base 1, upper backing plate 2, upper splint 3, stop plate 4, stripping plate 5, and the lower mold includes: lower template 8, lower backing plate 9 , Lower mold base 10. Assembly method: the upper backing plate 2 is fixed on the upper die base 1, the upper splint 3 is locked on the upper die base 1 with the long bolts passing through the upper backing plate 2, the upper splint 3 and the die base 1 are positioned with long pins, The baffle plate 4 is fixed on the stripper plate 5, the lower backing plate 9 is fixed on the lower mold base 10, the lower template 8 is locked on the lower mold base 10 with the long bolts passing through the lower backing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com