Clamping hoop curved tooling and clamping hoop U-shaped forming mold

A technology for forming molds and clamps, applied in the directions of forming tools, manufacturing tools, feeding devices, etc., can solve the problems of inaccurate bending radius, time-consuming processing, and troublesome processing and use, so as to improve processing efficiency and processing quality. , Guarantee position accuracy and machining accuracy, avoid the effect of left and right offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

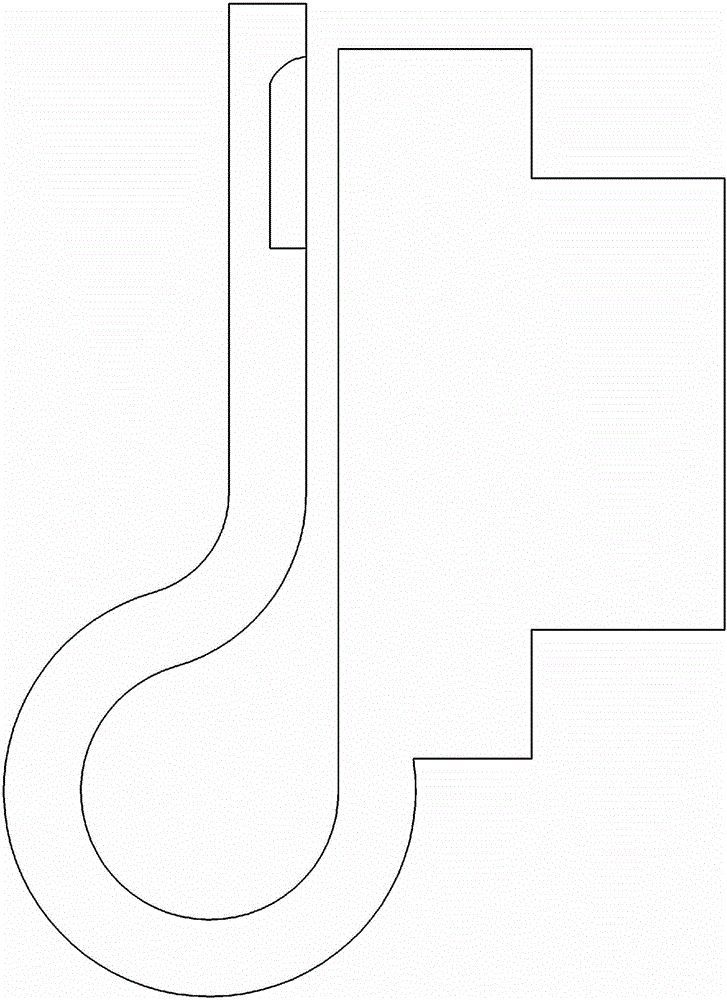

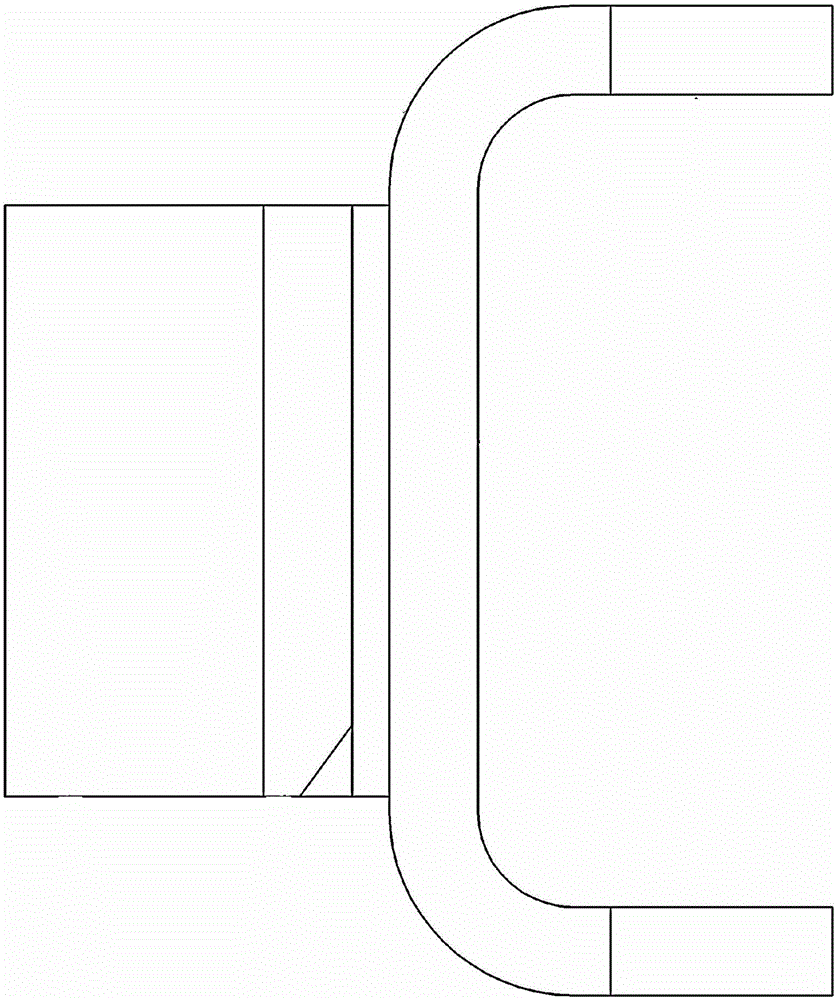

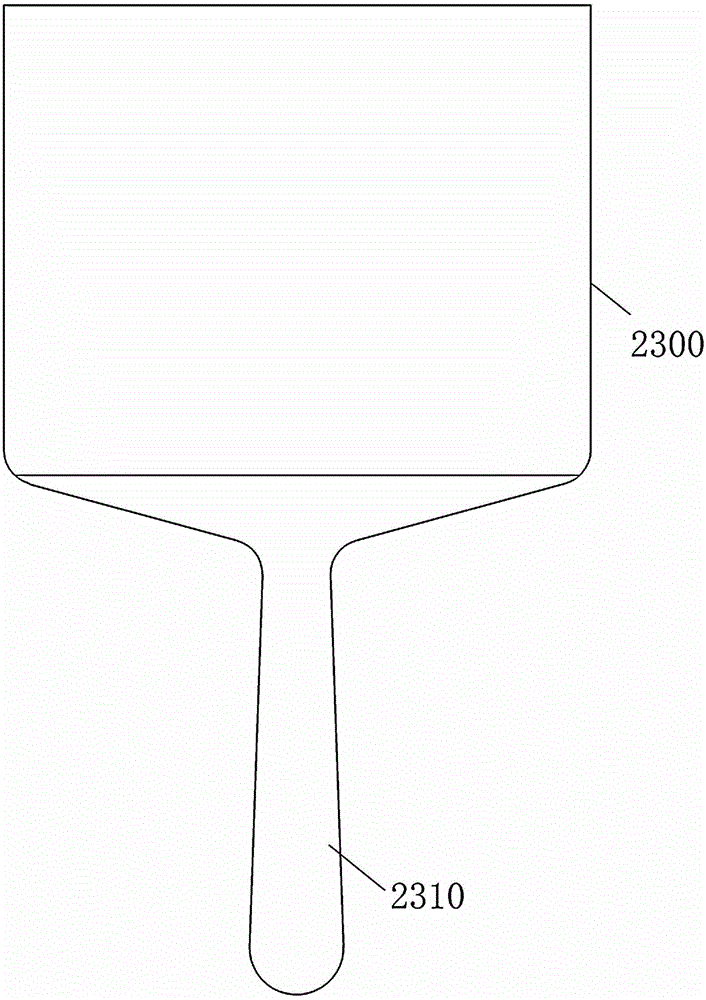

[0033] Embodiment of a kind of hoop bending tooling of the present invention: as Figure 6-19 As shown, the clamp bending tooling includes three sets of molding dies for sequentially completing the three processing steps, and the three sets of molding dies include upper and lower dies, as shown in Figure 6-9 Shown is the double lug forming tool used to process the first process, such as Figure 10-14 Shown is the clamp U-shape forming die used for processing the second process, such as Figure 15-19 Shown is the hoop arc forming mold for processing the third process. Of course, this embodiment provides a double-ear forming mold for processing the first process and a hoop arc forming mold for processing the third process. , in other embodiments, the first process and the third process can be replaced by existing manual processing.

[0034] The following is a detailed description of the three sets of molds in turn according to the drawings:

[0035] like Figure 6-7 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com