Combined heat-exchange dust remover for production of expanded perlite

A technology of expanded perlite and combined heat exchange, which is applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of high cost of dust removal, dust environmental pollution, environmental damage, etc., and achieve heat exchange and Both dust removal functions, reasonable resource utilization, and scientific design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

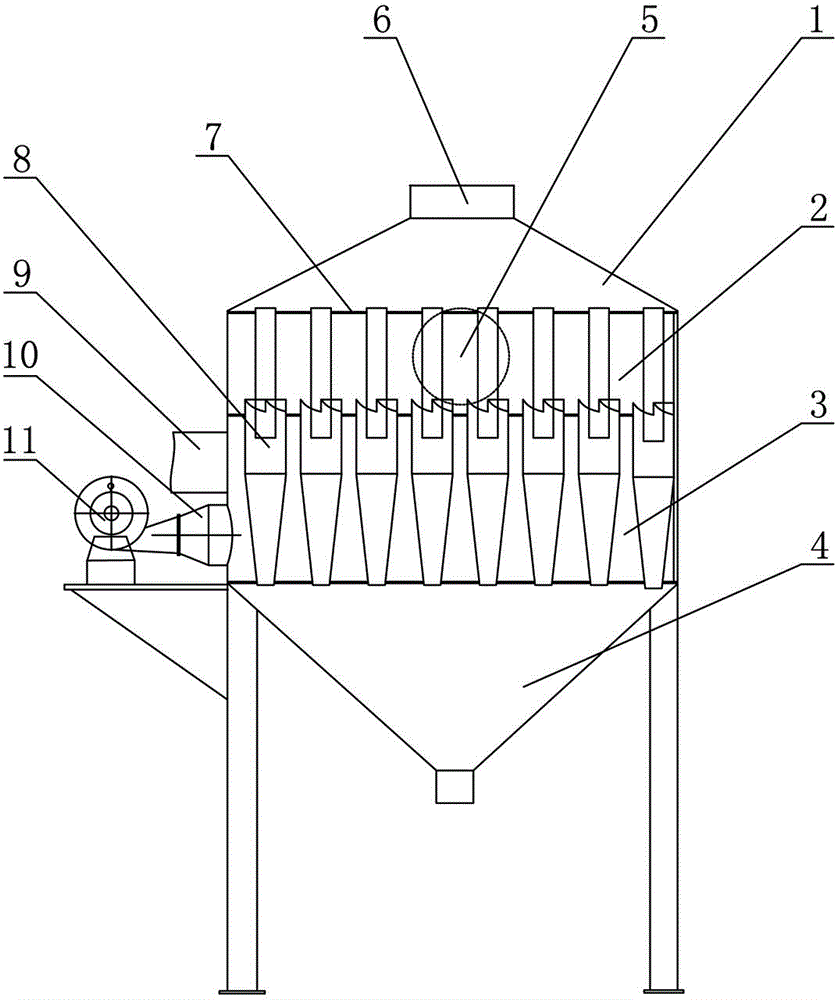

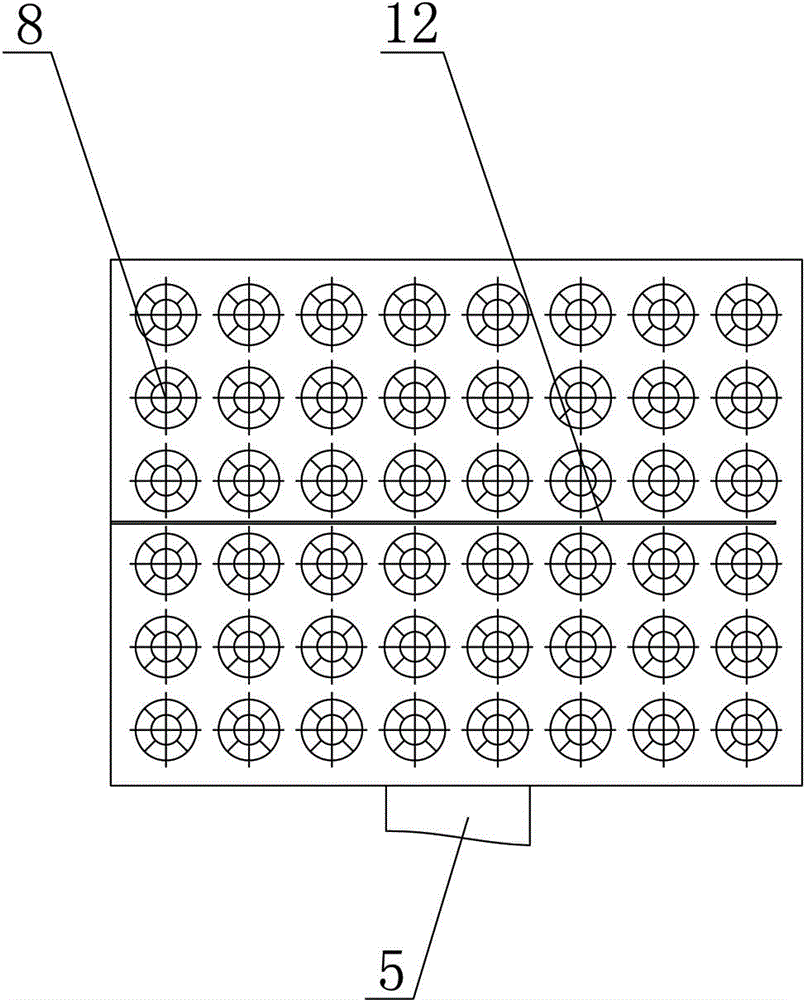

[0024] Such as figure 1 and figure 2 As shown, a combined heat exchange dust collector for expanded perlite production includes a shell, N rotors 8 evenly distributed in the shell, and a set of rotors 8 arranged in the shell from top to bottom and separated by a partition 7 Exhaust chamber 1, air intake chamber 2, heat exchange chamber 3 and dust removal chamber 4, said vortex 8 includes a vortex air inlet, a vortex air outlet and a rotator ash discharge port, and the rotator inlet of each said rotator 8 is connected The air inlet chamber 1, the air outlet of each rotor 8 communicates with the exhaust chamber 2, the rotor ash outlet of each rotor 8 communicates with the dust removal chamber 4, and the heat exchange chamber 3 is provided with There is a cold air inlet 10 and a hot air outlet 9, the cold air inlet 10 of the heat exchange chamber 3 is provided with a blower 11, the cold air inlet of the heat exchange chamber 3 is provided with a blower 11, and the heat exchange...

Embodiment 2

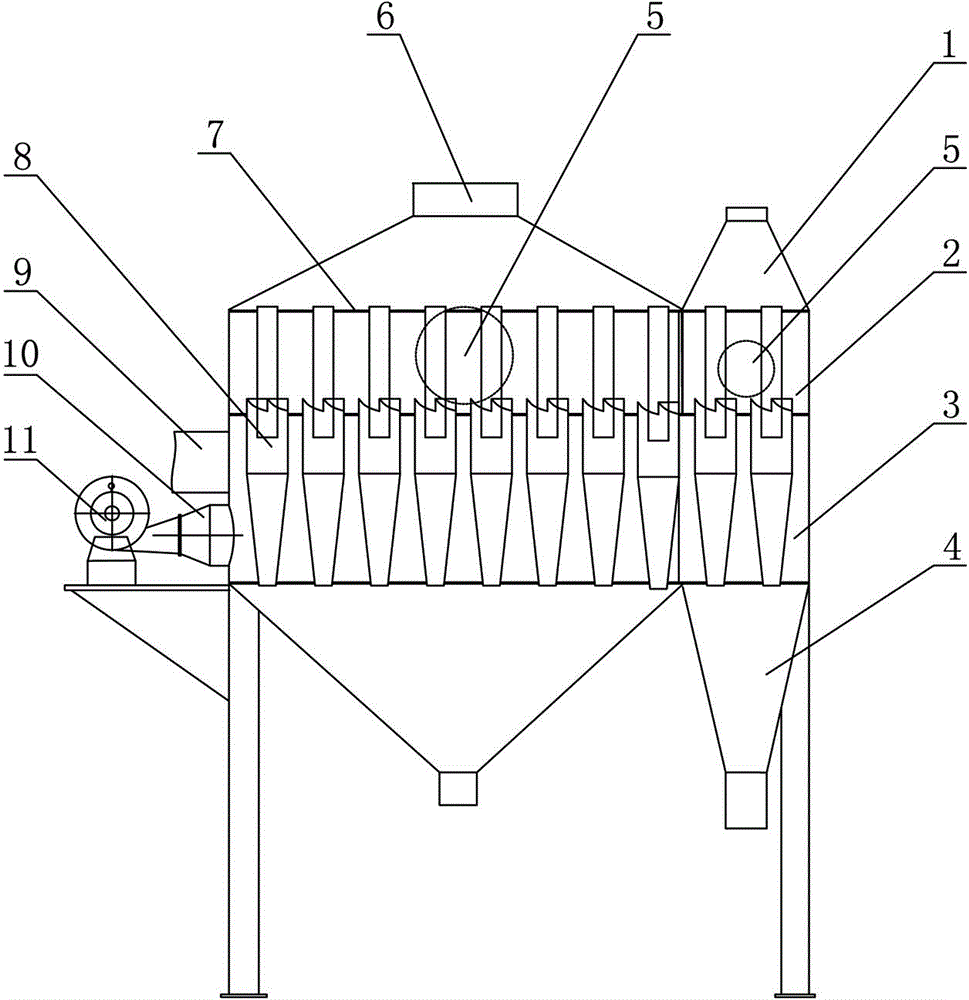

[0026] Such as image 3 and Figure 4 As shown, a combined heat exchange dust collector for expanded perlite production includes at least two close-fitting shells, and each shell is arranged in the shell from top to bottom and is separated by a partition plate Exhaust chamber 1, The air intake chamber 2, the heat exchange chamber 3 and the dust removal chamber 4, the air inlet of each rotor 8 communicates with the air intake chamber 2, and the air outlet of each rotor 8 communicates with the exhaust chamber 1 , the dust discharge port of each rotor 8 is connected to the dust removal chamber 4, and all the heat exchange chambers 3 are connected to form a heat exchange channel, and the heat exchange channel is provided with a cold air inlet and a hot air outlet, and the heat exchange chamber 3 corresponds to The cylinder part of the rotor 8 is set, the air inlet chamber 2 has a smoke inlet, the exhaust chamber 1 has an exhaust outlet, and the lower end of the dust removal chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com