Device and method to eliminate fluff from a yarn

A technology for yarn and hair removal, which is applied in singeing, textile and papermaking, and fabric surface trimming, etc. It can solve problems such as poor process performance, vibration, and unstable yarn, so as to improve equipment efficiency, increase efficiency, and reduce The effect of unit energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

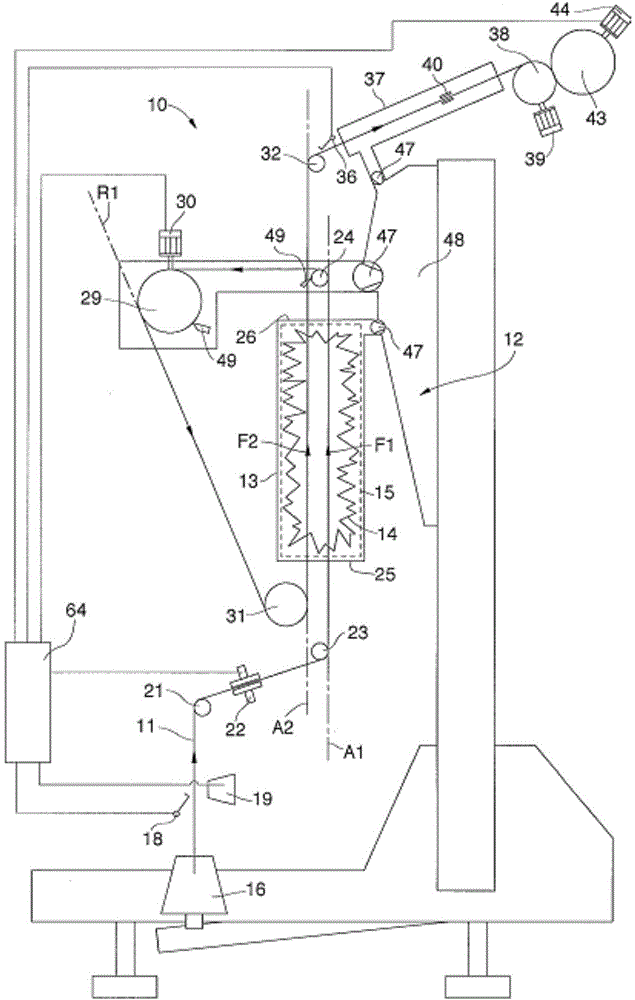

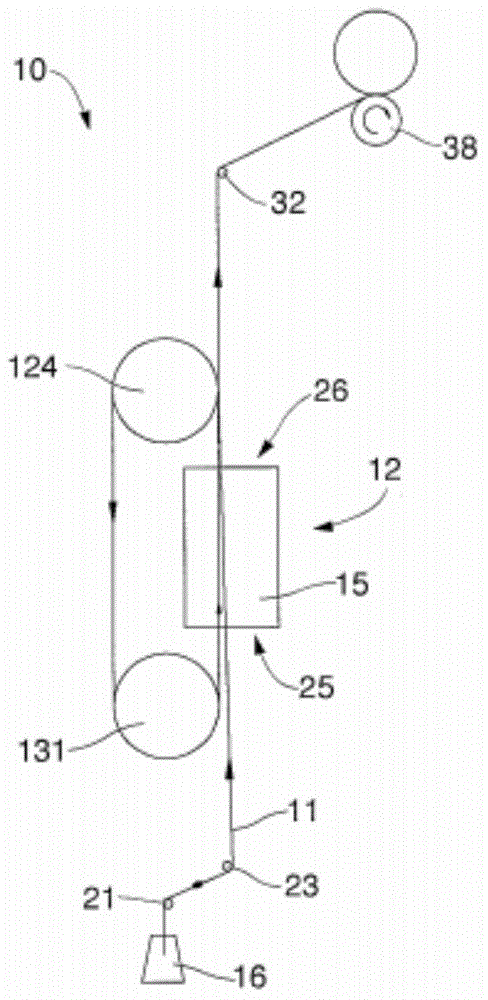

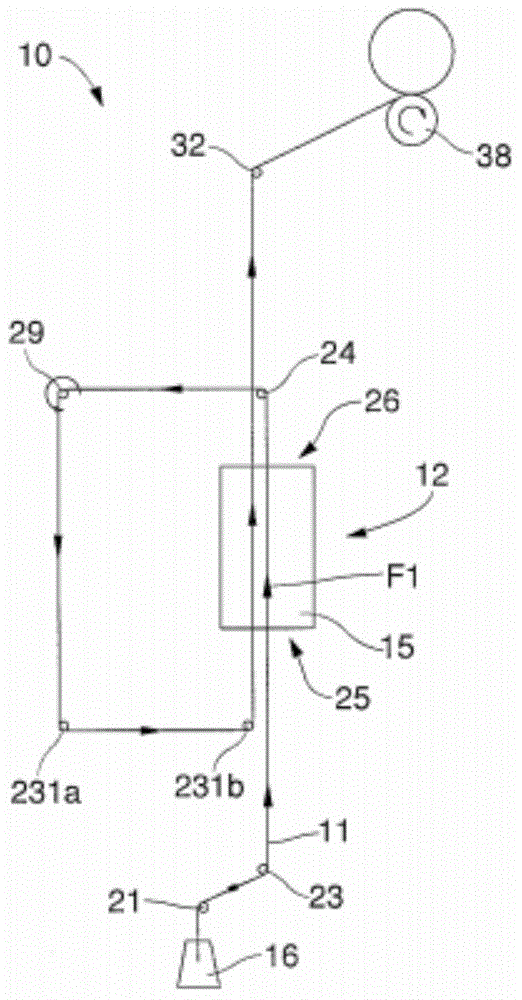

[0050] refer to figure 1 , according to the present invention, a kind of device for eliminating hairiness of yarn 11, its whole is marked by reference number 10, is provided with a singeing machine 12 in it, and this singeing machine 12 comprises a generator device 13 for generating energy source 14, It defines a treatment area 15 into which the yarn 11 is transferred and subjected to a dehairing treatment.

[0051] Energy source 14 may be, for example, a flame produced by a gas burner. However, other energy sources may be used instead, such as an energy source capable of producing an electric arc or other sources of energy suitable for the combustion treatment of the yarn, in accordance with the teachings of the present invention.

[0052] Hereinafter, we will mainly describe flames as the above-mentioned non-limiting means.

[0053] Such as figure 1 A kind of embodiment mode shown, yarn 11 is unclamped from reel 16, is controlled by the first sensor of probe 18, and hairi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com