Insulation puncture cable connecting device

A connecting device and insulation piercing technology, applied in the direction of needle tip/slotted plate contact and conductive connection used for connecting and penetrating insulated wire/cable core wire, can solve the problems of low installation efficiency, inconvenient operation, etc. Simple on-site construction and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

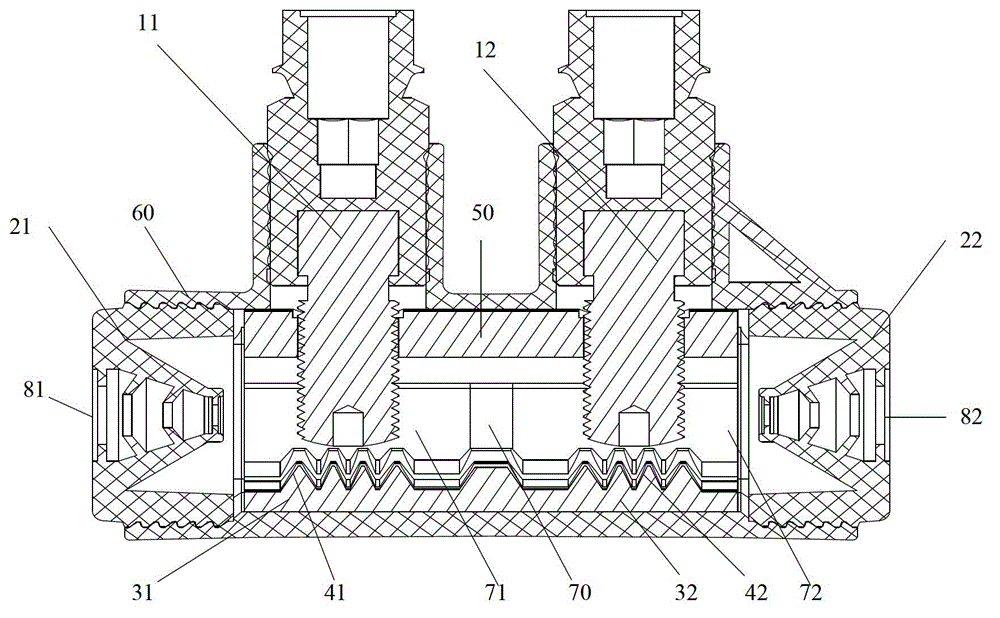

[0024] figure 1 It is a cross-sectional view of an insulation piercing cable connection device in a preferred embodiment of the present invention, such as figure 1 As shown, the insulation piercing cable connection device involved in this embodiment includes: torque bolt 11, torque bolt 12, cable receiving part 50, tapered pier array 41, tapered pier array 42, anvil 31 and anvil 32;

[0025] Wherein, the cable accommodating part 50 is used for accommodating the cables to be connected; the torque bolts 11 and the torque bolts 12 are used to provide thrust for the cables extending into the cable accommodating part 50; the anvil 31 and the anvil 32 are placed in the cable accommodating part 50, used to clamp the cable together with the torque bolt 11 and the torque bolt 12 respectively in the direction of thrust;

[0026] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com