Experimental device for hydrate formation in combined multiphase fluid pipeline

A technology for hydrate generation and experimental equipment, which is used in measurement equipment, instruments, scientific instruments and other directions to achieve the effect of enhancing sealing, precise control, and meeting the requirements of high-precision experiments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

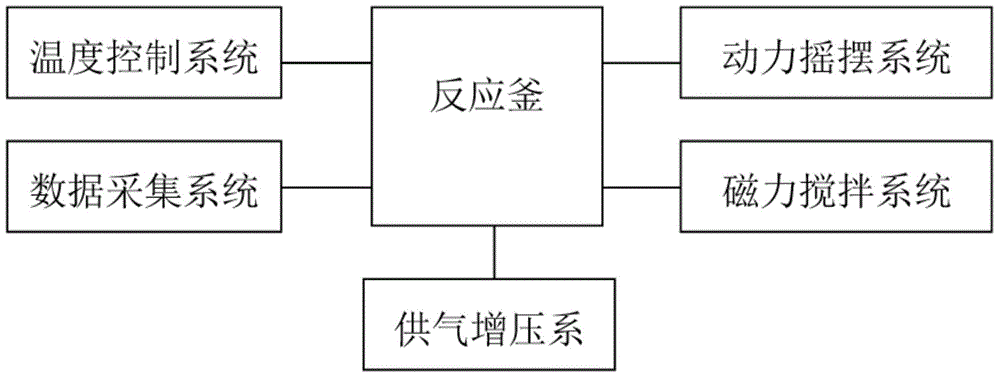

[0034] figure 1 Shown is the block diagram of the working principle of the hydrate formation experimental device in the combined multiphase fluid pipeline. After pressing, put it into the reaction kettle, turn on the temperature control water bath to control the temperature of the reaction kettle, turn on the power swing system or magnetic stirring system, so that the gas and liquid in the reaction kettle are mixed in multiphase and form hydrate. The working parameters during the reaction process are temperature, The pressure is collected and analyzed in real time by the data acquisition system. During the reaction, the camera is used to record the hydrate formation in the reactor through the visualization window.

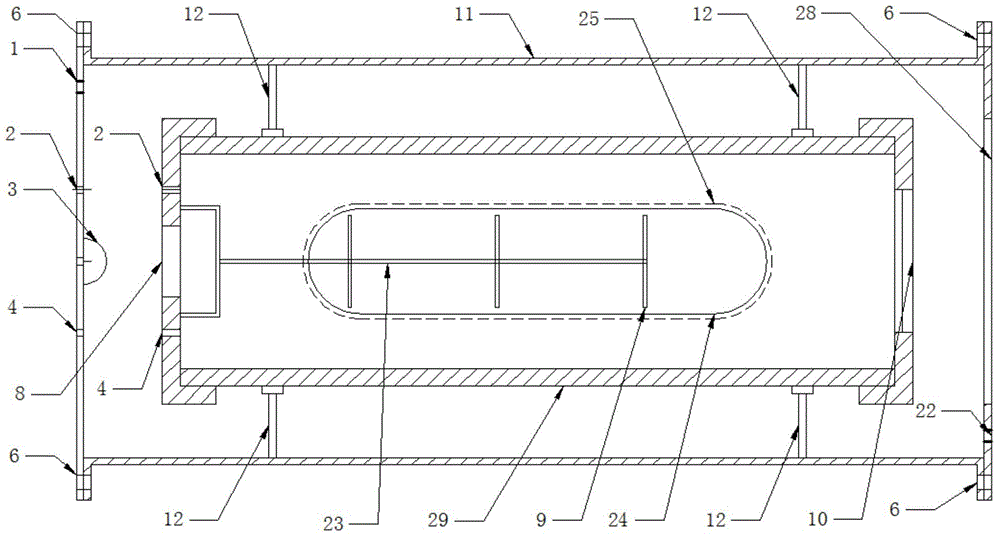

[0035] figure 2 Shown is the internal structure diagram of the reactor of the experimental device for hydrate formation in the combined multi-phase fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com