Open shell and tube condenser

A shell-and-tube condenser technology, which is applied in the field of mechanical devices, can solve the problems of reduced condensation effect, inconvenient collection, and inability to detect corrosion of condenser heat transfer tubes in time, and achieve the effect of increasing height and facilitating discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

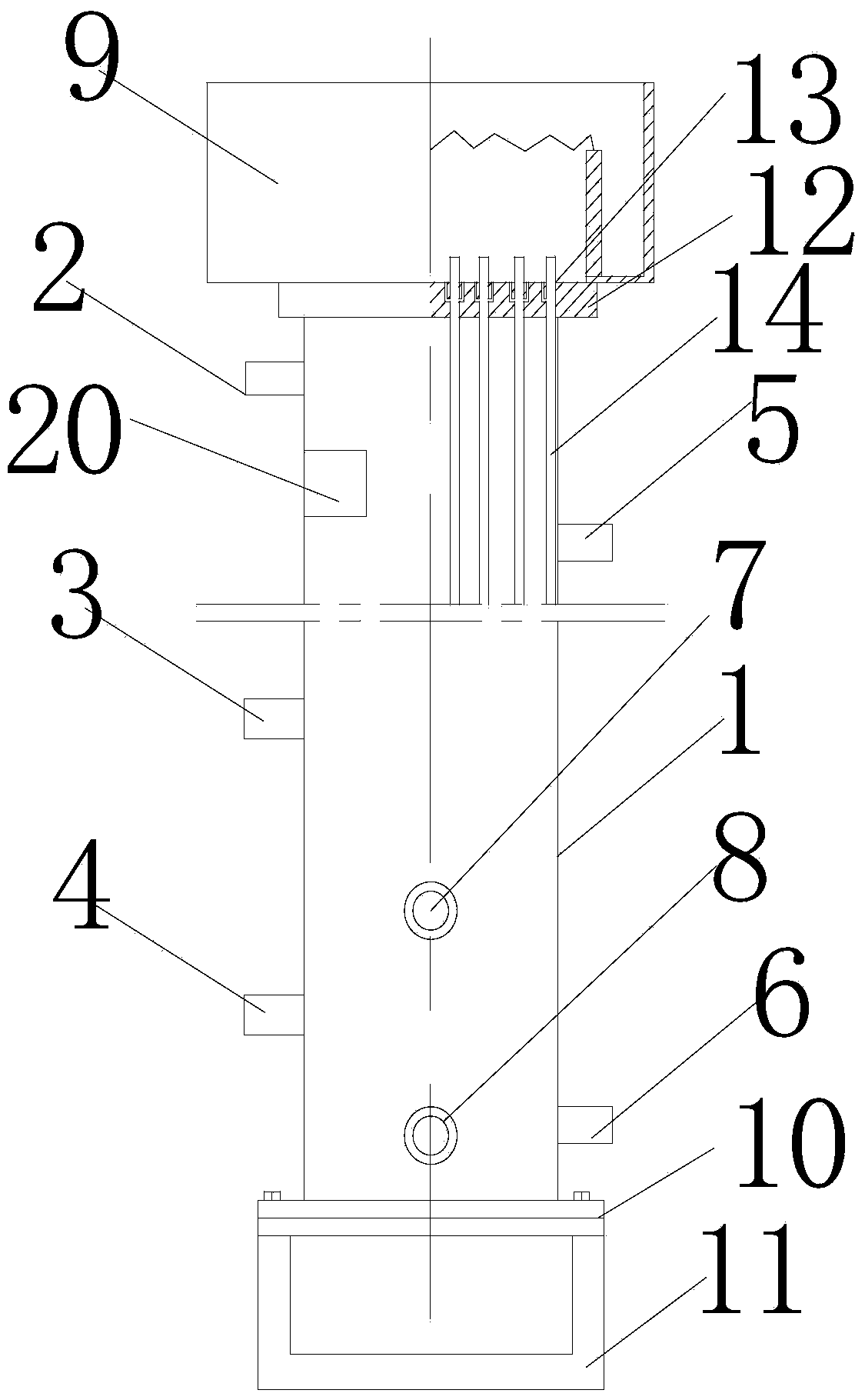

[0018] see Figure 1-Figure 4 As shown, it includes a cylindrical shell 1, one side of the shell is respectively provided with a safety valve joint 2, a pressure equalizing pipe 3, and an air release pipe 4 from top to bottom, and the other side is respectively provided with an inlet pipe from top to bottom. Air pipe 5 and liquid outlet pipe 6; the front side of the housing is provided with a pressure gauge 7 and an oil discharge pipe 8 respectively from top to bottom, a water distribution tank 9 is provided at the top of the housing, and a base 10 is provided at the bottom of the housing; Both sides of the base are connected to the support frame 11; a condensing device is provided in the housing, and the condensing device includes a tube plate 12 arranged at both ends of the housing, and a plurality of mounting holes 13 are opened on the tube plate, and the mounting holes are installed There are heat transfer tubes 14; the top of the housing is provided with a perspective win...

Embodiment 2

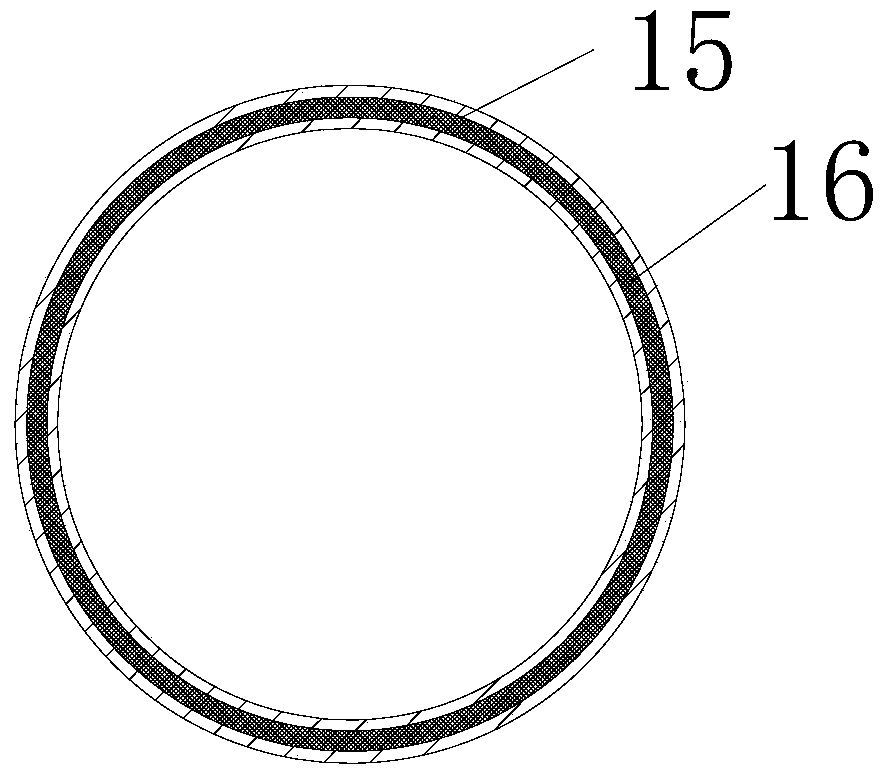

[0023] On the basis of the foregoing embodiments, an annular groove 15 is provided on the end surface of the housing along its length direction, and a damping interlayer 16 is provided in the annular groove. The damping interlayer is arranged in the annular groove, which is beneficial to shock and noise reduction.

[0024] Preferably, the damping interlayer adopts rubber and plastic damping plates.

Embodiment 3

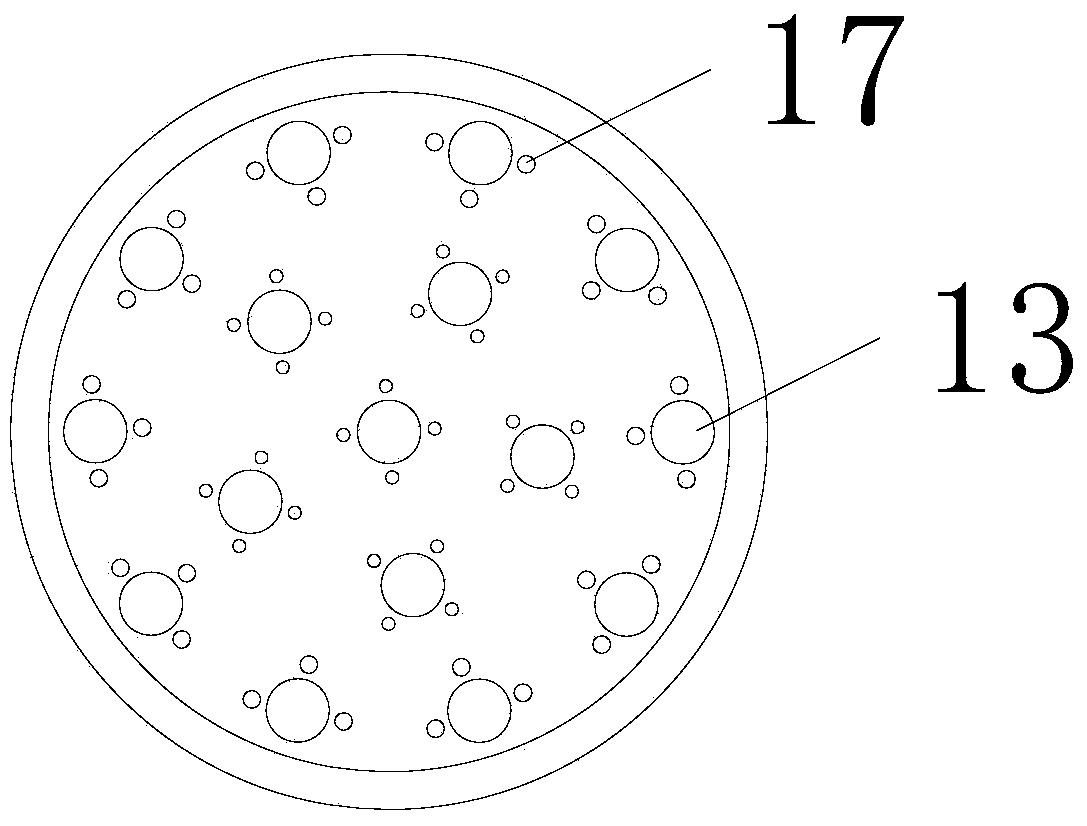

[0026] On the basis of Embodiment 1, several return holes 17 are provided around the installation holes on the tube plate. The combination of the return hole and the installation hole will form a turbulent flow when the cooling water passes through the return hole, and ensure the flow rate of the cooling water, so that the heat exchange of the cooling water is more sufficient, thereby improving the condensation efficiency of the condenser.

[0027] Preferably, the diameter of the return hole is 4-7mm. When the diameter of the return hole is 4-7 mm, the effect of generating turbulent flow is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com