Pendulous eddy current tuned mass damper vibration reduction control device

A technology of tuning mass damping and eddy current damping, which is applied to bridge parts, building components, bridges, etc., to achieve the effects of ensuring stability, simple adjustment methods, and ensuring sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

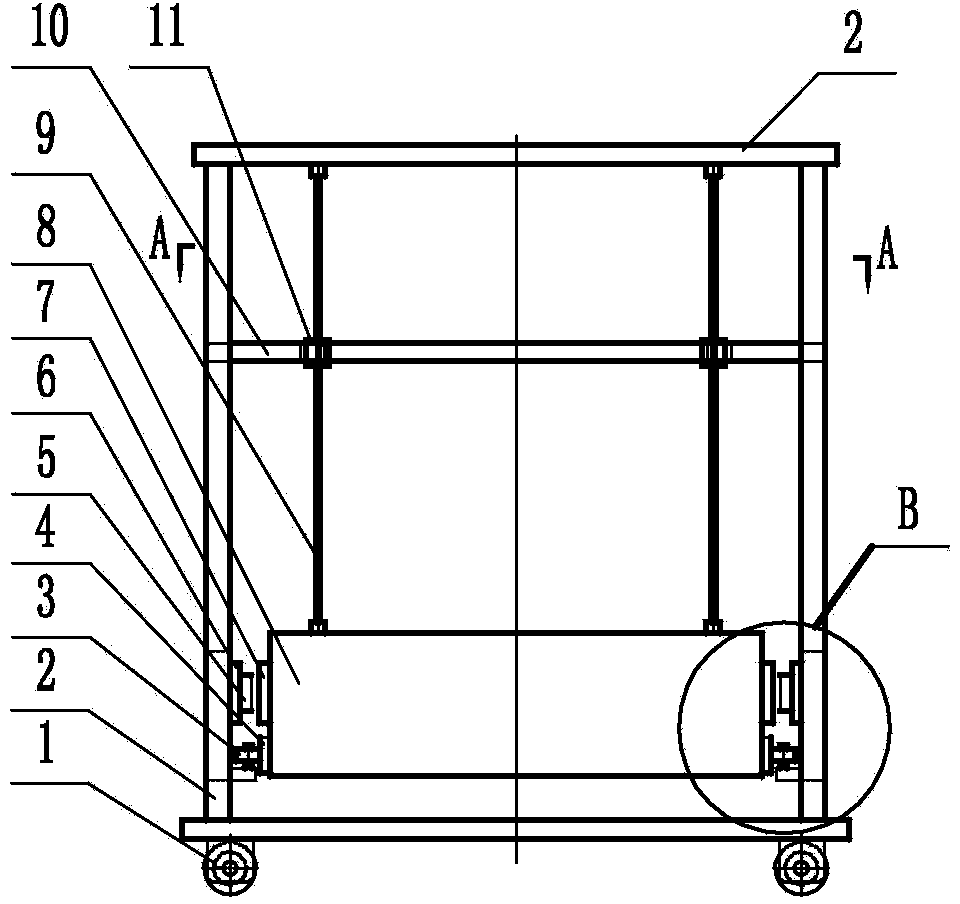

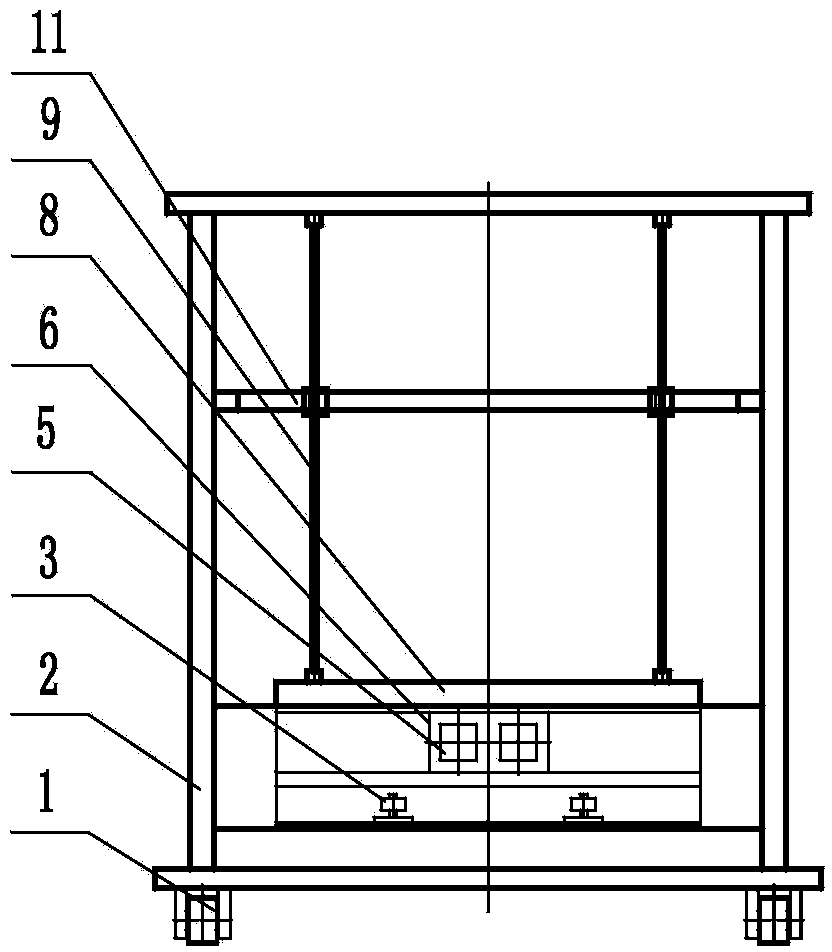

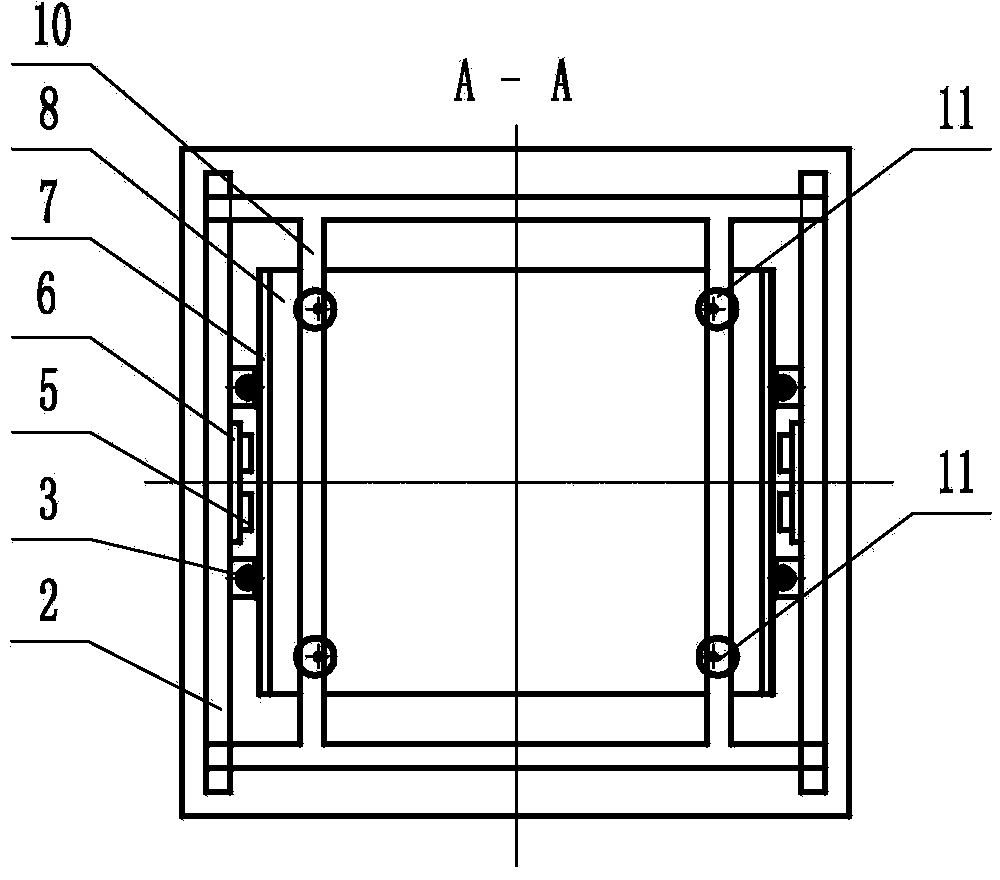

[0042] A pendulum type eddy current tuned mass damper vibration reduction control device, comprising a bracket 2, a mass 8, an eddy current damping system and a guide mechanism, the mass is suspended on the bracket 2 by four pendulum ropes 9;

[0043] The eddy current damping system is installed on one side or both sides of the swing direction of the mass block. The eddy current damping system includes a permanent magnet 5 and a conductor plate 7. The conductor plate 7 is installed on the side of the mass block. The permanent magnet 5 passes through the permanent magnet. The mounting plate 6 is installed on the inner side of the bracket corresponding to the conductor plate, and maintains a certain gap with the conductor plate 7; It is fixed on both sides of the mass block, and the guide bearing is installed on both sides of the bracket corresponding to the guide plate, and is in rolling contact with the guide plate;

[0044] The pendulum length adjustment part 10 is installed on...

Embodiment 2

[0047] A pendulum-type eddy-current tuned mass damper vibration control device, the basic structure of which is the same as that of Embodiment 1, including a bracket, a mass, an eddy-current damping system and a guiding mechanism; the difference is:

[0048] The mass block is suspended on the top of the support by 2 pendulum ropes (see attached Figure 5 ~ Figure 7 ).

Embodiment 3

[0050] A pendulum-type eddy-current tuned mass damper vibration control device, the basic structure of which is the same as that of Embodiment 1, including a bracket, a mass, an eddy-current damping system and a guiding mechanism; the difference is:

[0051] The mass block is suspended on the top of the support by a pendulum rope (see attached Figure 8 ~ Figure 10 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com